Knife grinder for hay cutter

A knife sharpening device and chaff cutter technology, which is applied in the direction of grinding automatic control device, grinding workpiece support, grinding machine tool parts, etc., can solve the problems of blade damage, safety accidents of sparks and iron filings, uneven blade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is realized through the following technical solutions:

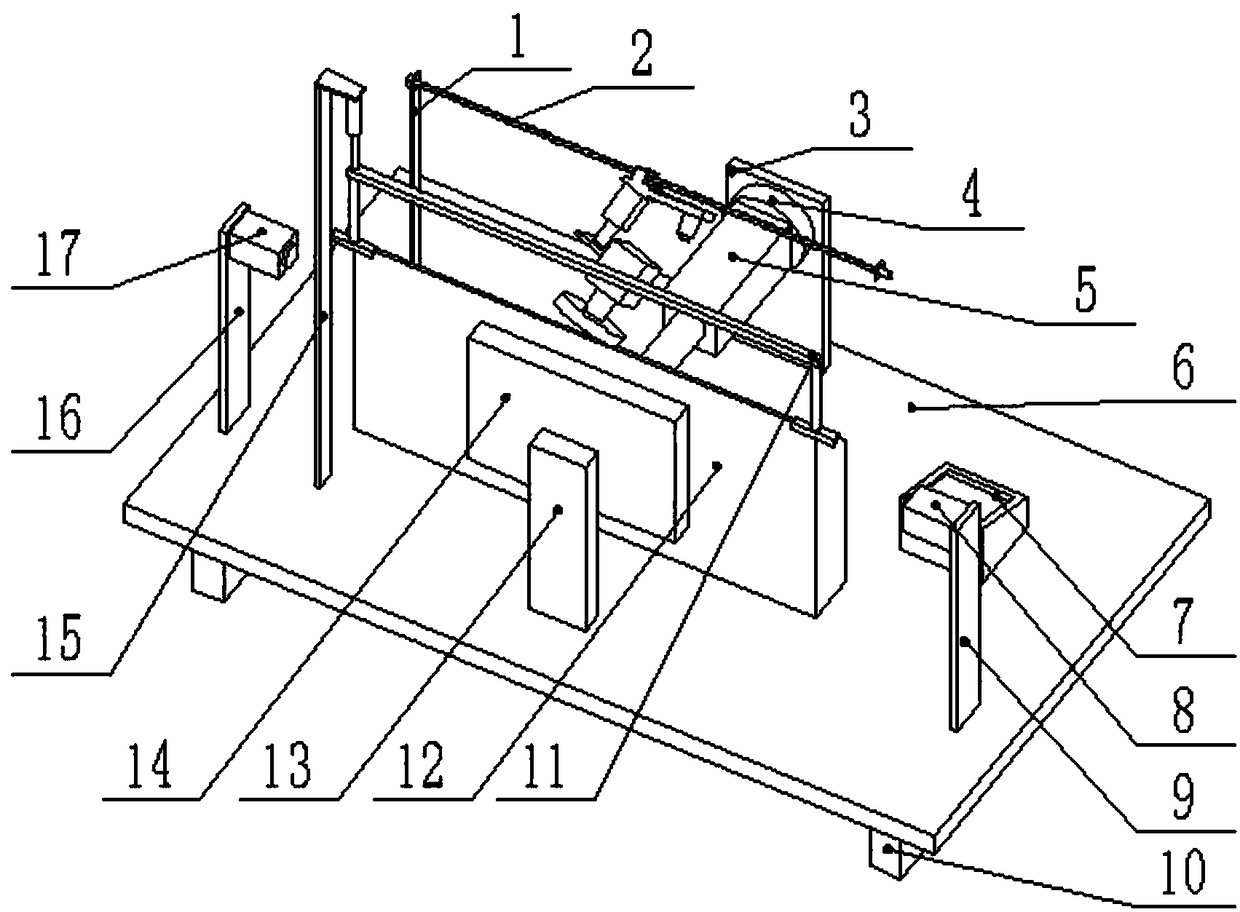

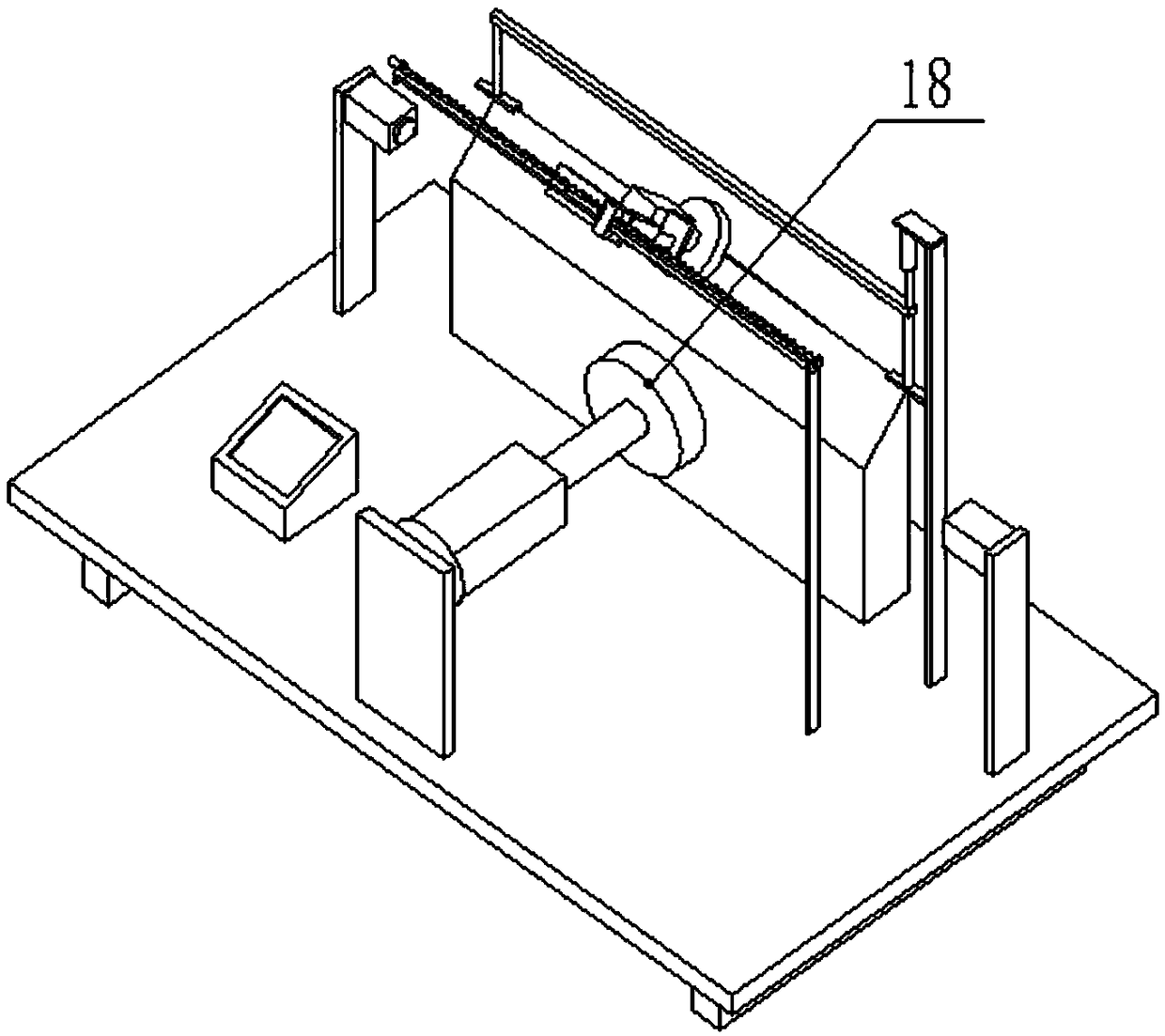

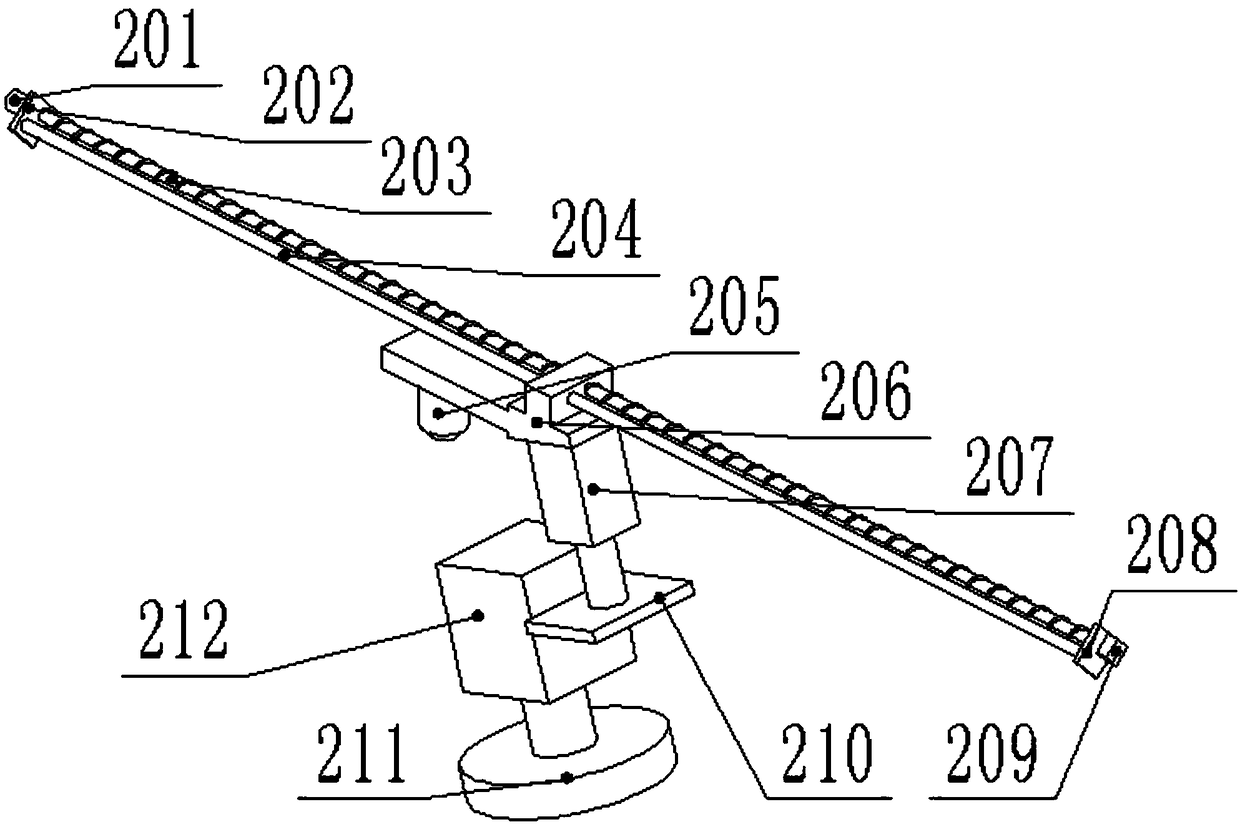

[0017] A knife sharpening device for a hay cutter, comprising a first bracket 1, a grinding device 2, a second bracket 3, a pressure sensor 4, a first hydraulic cylinder 5, a workbench 6, a controller 7, a first ultrasonic sensor 8, a second Three brackets 9, supporting legs 10, limiting device 11, blade 12, the fourth bracket 13, limiting plate 14, the fifth bracket 15, the sixth bracket 16, the second ultrasonic sensor 17 and rubber backing plate 18, the first A support 1 is fixed on the workbench 6, the grinding device 2 is installed on the top of the first support 1, the second support 3 is fixed on the center of the rear end of the workbench 6, and the pressure sensor 4 is installed on the second support 3 , used to detect the pressure between the rubber pad 18 and the blade 12 to prevent excessive pressure from damaging the blade 12, the first hydraulic cylinder 5 is installed on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com