Toll for preventing missing cutting clamp spring grooves of welding fork product

A circlip groove and welding fork technology is applied in the field of welding fork product circlip groove leak-proof cutting tooling, which can solve the problem of product prevention that cannot completely prevent the leakage of products from leaking processes, the leakage process products flow into the next process, and the products that cannot be circlip grooves. Error and other problems, to achieve the effect of automatic screening, realization of error prevention effect, and elimination of outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the drawings:

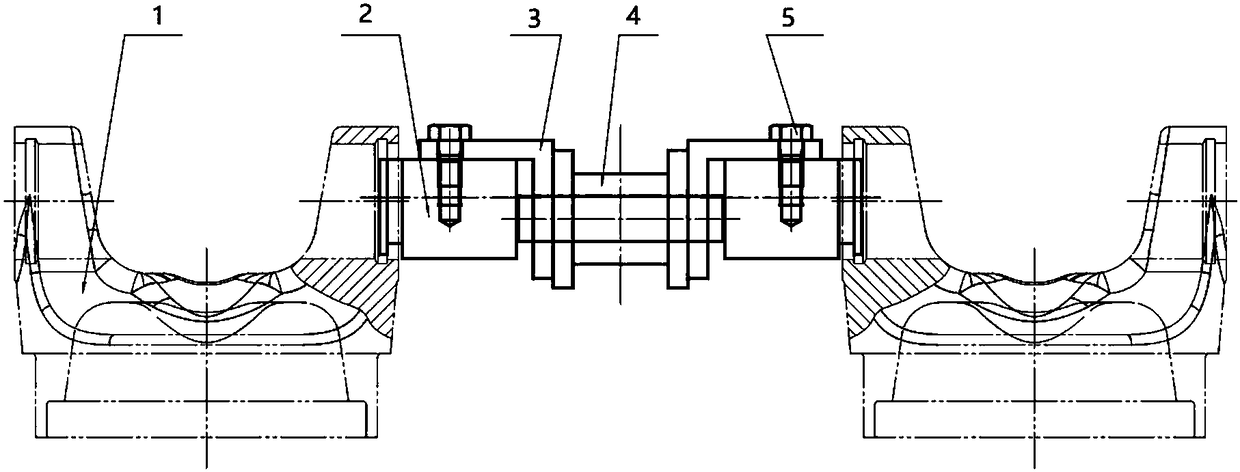

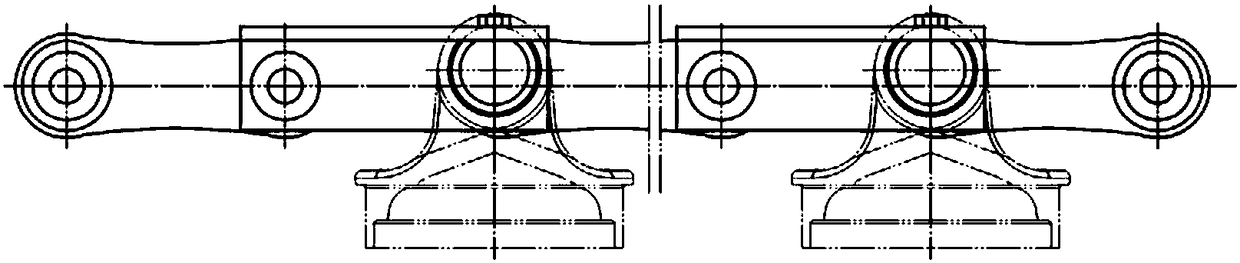

[0019] As shown in the figure, this kind of welding fork product circlip groove leak-proof cutting tooling mainly includes welding fork 1, positioning pin 2, chain plate 3, chain 4, hexagon bolt 5, chain plate 3 is installed at both ends of chain 4 , The chain plate 3 is connected and fixed to the positioning pin shaft 2 by the hexagonal bolt 5, and the outer end of the positioning pin shaft 2 is matched with the welding fork 1 installed.

[0020] The welding fork 1 is an axially symmetrical part. Both sides of the welding fork 1 are provided with ear holes 11 and a retaining ring groove 12, and the retaining ring groove 12 is positioned in cooperation with the positioning shaft diameter 21 on the positioning pin 2. The ear hole 11 and the circlip groove 12 are used to position the workpiece, and the workpiece circlip groove 12 is inserted into the conveyor chain. If the product fails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com