Multi-layer in-situ agent injection method for contaminated site

A multi-level, drug injection technology, applied in the field of contaminated soil remediation, can solve the problems of increasing the vertical distance of conveying, repairing drug waste, increasing the difficulty of drug injection, etc., to reduce loss, prevent blockage, and improve the effect of drug utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

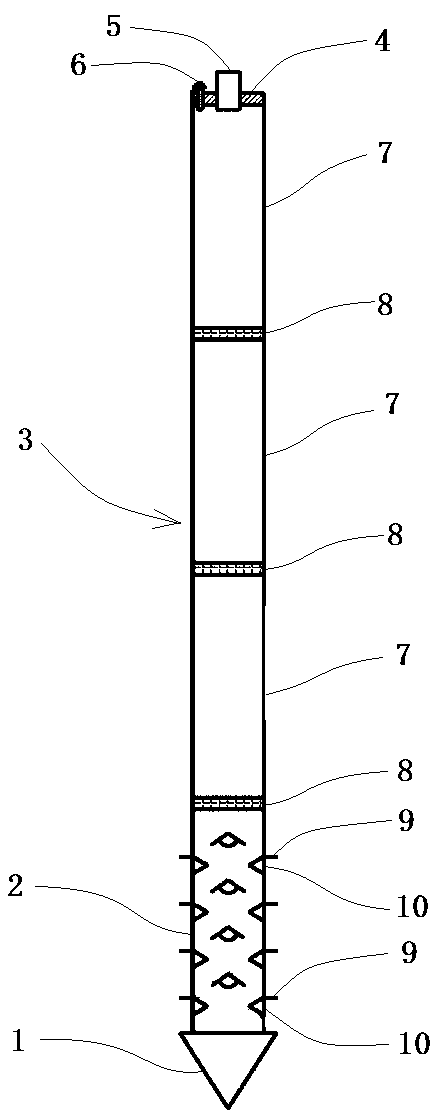

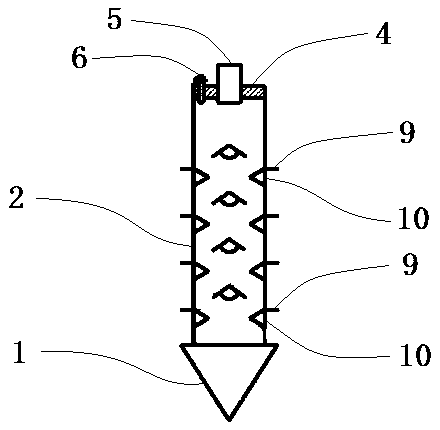

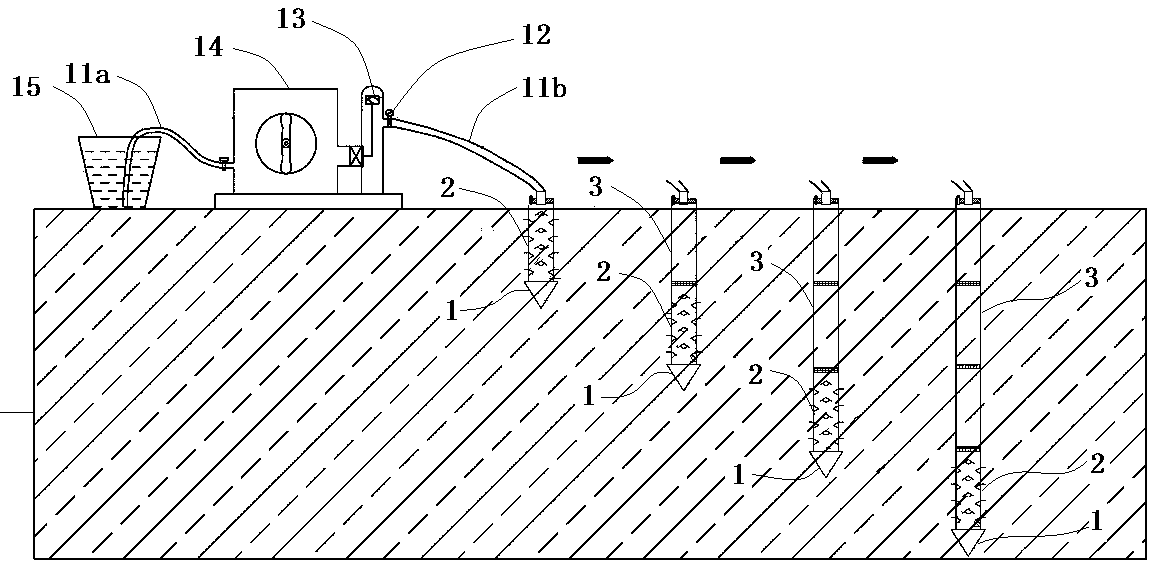

[0021] Example: such as figure 1 , 2 , 3, this embodiment specifically relates to a multi-level in-situ injection method for contaminated sites, the injection method specifically includes the following steps:

[0022] (1) Obtain the stratum distribution of the contaminated area to be repaired through exploration, and then evenly arrange a number of injection points within the contaminated area to be repaired; the injection point layout spacing is set to 2m * 2m, and the spacing can be densely arranged in severely polluted areas; at the same time , in each injection point, determine the depths at all levels that need to be repaired by injection. For example, in this embodiment, the depth of the first level is 0.5m, the depth of the second level is 1.0m, and the depth of the third level is 1.5m... the nth level The level depth is 0.5n m;

[0023] (2) Complete the preparation of the repairing medicine solution in the medicine mixing tank 15, and connect the medicine mixing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com