A kind of fly ash synthetic zeolite and its preparation method and application

A technology for synthesizing zeolite and fly ash, applied in the field of selenium fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 fly ash synthetic zeolite

[0030] 1. Preparation of fly ash synthetic zeolite

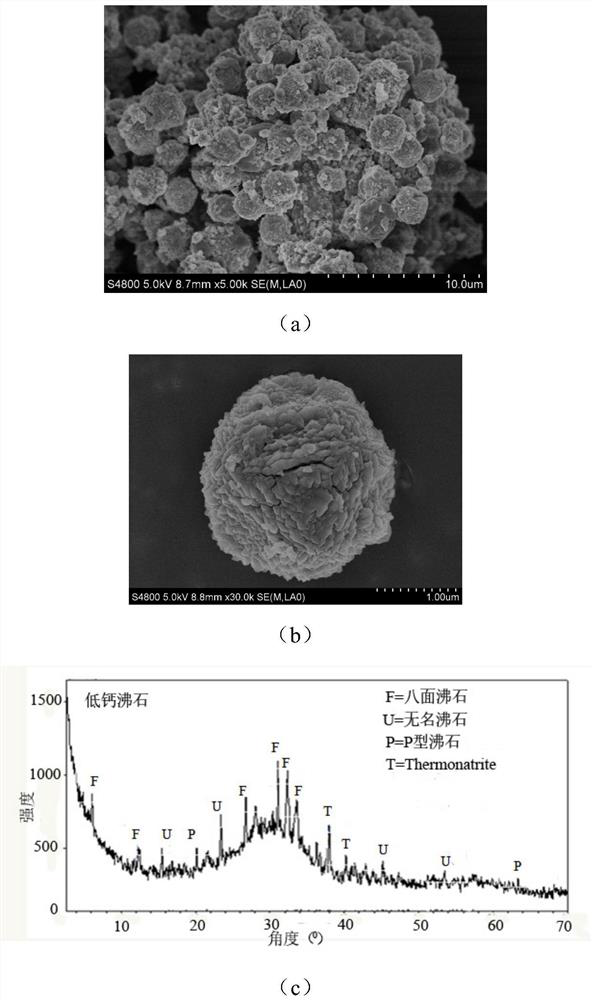

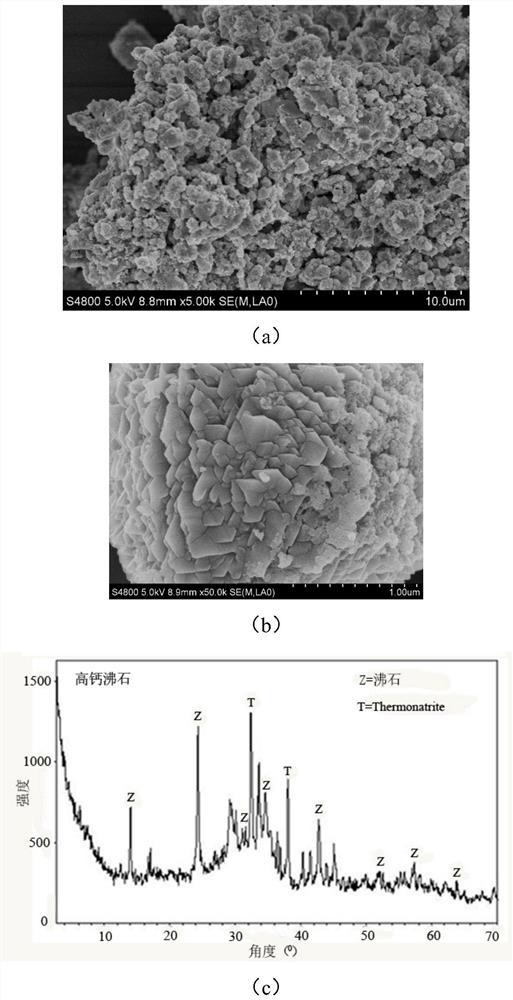

[0031] The zeolite was synthesized by alkali fusion-hydrothermal method, and the specific synthesis process was as follows: Accurately weighed 12g of sodium hydroxide (analytical pure) solid and 10g of fly ash, put them into a pulverizer and mixed them evenly, and then put the mixture into a 600°C horsepower Melt in a Furnace for 3 hours, take it out after cooling and pulverize the melt, weigh it and add the mixture into distilled water according to the ratio of solid to liquid 17.25%, then put it into a constant temperature water bath and stir slowly at 80°C for 2 hours. After taking it out, put it into a reaction kettle and place it in an oven at 100°C for 9 hours to crystallize. Take out the solid and wash it with distilled water until the pH is 9-10, then place it in a watch glass and put it in an oven at 100°C for 12 hours.

[0032] 2. Characterization...

Embodiment 2

[0039] The specific application of embodiment 2 fly ash synthetic zeolite as adsorbent

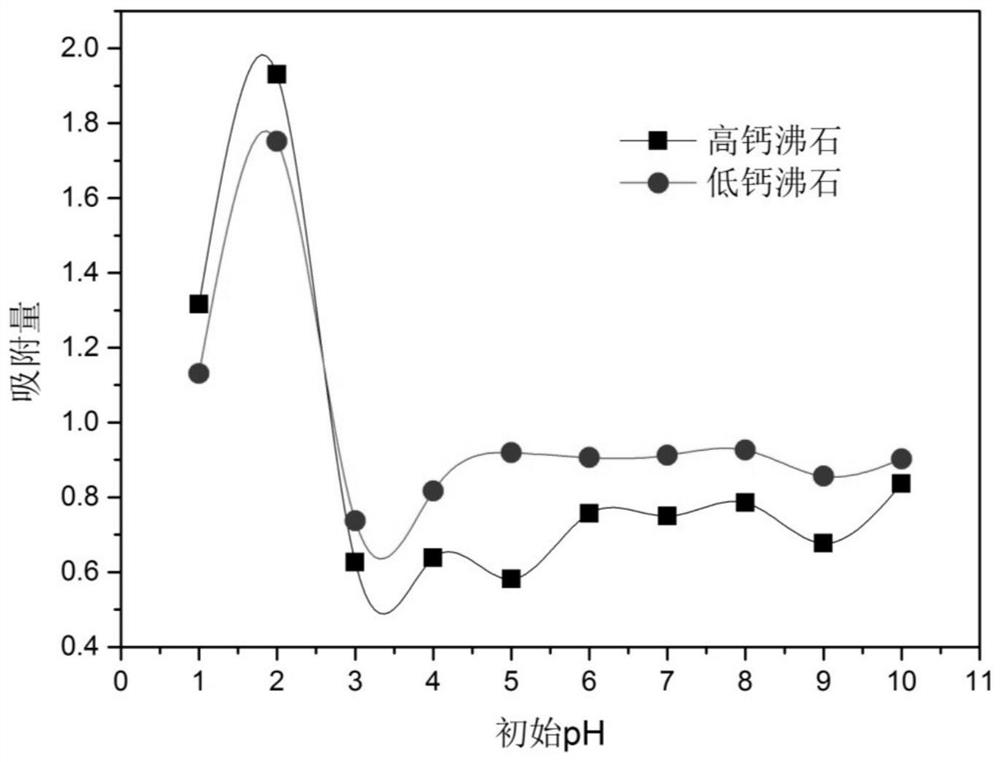

[0040] 1. Adsorption

[0041] Sodium selenite (Na2SeO3), synthetic zeolite from fly ash, and water are used to configure a solution in a ratio of 219:500:10000, and the pH of the solution is adjusted to 2.0±0.05. The mixed solution was shaken and adsorbed at 25°C and 150rpm in a constant temperature shaking incubator for 6h. After shaking the adsorption equilibrium, the mixture was centrifuged, and the adsorbed saturated solid was taken out and dried in a constant temperature oven at 100°C for 12 hours, and then ground into a powder for future use.

[0042] 2. Desorption (release)

[0043] The adsorption saturated zeolite product and water were formulated into a solution at a ratio of 1:200, the pH of the solution was adjusted to about 7, and the mixed solution was shaken and released at 25°C and 150rpm in a constant temperature shaking incubator for 6 hours. Then spray the solution eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com