Industrial waste gas treatment device of U-shaped washing tower

An industrial waste gas and treatment device technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of low water and gas separation efficiency, excessive volume, etc., to improve the spray process and dehumidification efficiency, reduce wind resistance, Low wind resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the invention content, features and effects of the present invention, the following embodiments are exemplified and described in detail with reference to the accompanying drawings.

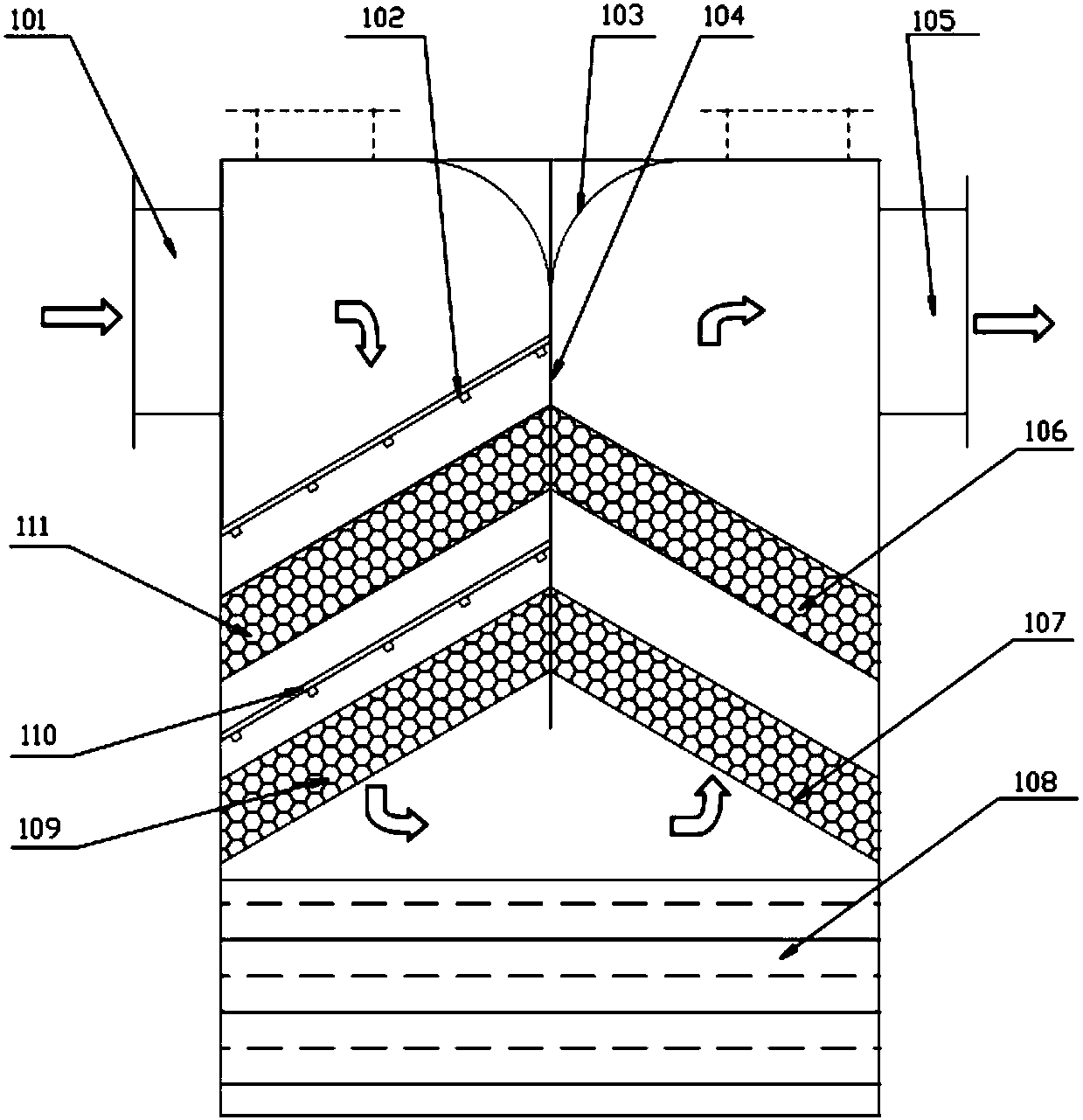

[0025] see figure 1 :

[0026] An industrial waste gas treatment device for a U-shaped washing tower, including a water tank, the upper part of the water tank is provided with a partition plate 104, and the partition plate 104 divides the upper part of the water tank into an air inlet chamber and an air outlet chamber, and the water tank is provided with a wall connected to the air inlet chamber. The air inlet 101 and the air outlet 105 communicated with the air outlet chamber; the air inlet chamber 101 and the air outlet chamber 105 are all provided with a multi-layered inclined packing layer, and the upper part of the packing layer located in the air inlet chamber is provided with Atomizing and spraying nozzles; circulating water is provided at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com