Whitening and pigment removing liquid and preparation method thereof

A discoloration and whitening technology, applied in the field of whitening and discoloring solution and its preparation, can solve the problems of skin darkening, pigment rebound, loss of activity, etc., and achieve the effects of skin tenderness, moisturizing, transdermal absorption, and anti-aging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of whitening discoloration liquid, comprise the raw material of following percentage: Comprising the raw material of following percentage: water is 55%, butylene glycol is 5%, propylene glycol is 5%, phenylethyl resorcinol is 0.8%, coagulant is 1%, glycerin 8%, collagen 4%, hyaluronic acid 0.9%, grape fruit extract 4%, arnica flower extract 4%, oligopeptide-1 4%, oligopeptide-5 4% for oligopeptide-2 and 0.3% for methylparaben.

Embodiment 2

[0048] A whitening and color-removing solution, 60% of water, 7% of butylene glycol, 7% of propylene glycol, 0.5% of phenylethyl resorcinol, 0.7% of blood coagulant, 6% of glycerin, and 3% of collagen , hyaluronic acid 0.6%, grape fruit extract 3%, arnica flower extract 3%, oligopeptide-1 3%, oligopeptide-5 3%, oligopeptide-2 3% and Methylparaben is 0.2%.

Embodiment 3

[0050] A kind of whitening discoloration liquid, comprise the raw material of following percentage: Comprising the raw material of following percentage: water is 65%, butylene glycol is 9.5%, propylene glycol is 9.5%, phenylethylresorcinol is 0.2%, blood coagulant is 0.5%, glycerin 5%, collagen 2%, hyaluronic acid 0.2%, grape fruit extract 1%, arnica flower extract 1%, oligopeptide-1 2%, oligopeptide-5 2% for oligopeptide-2 and 0.1% for methylparaben.

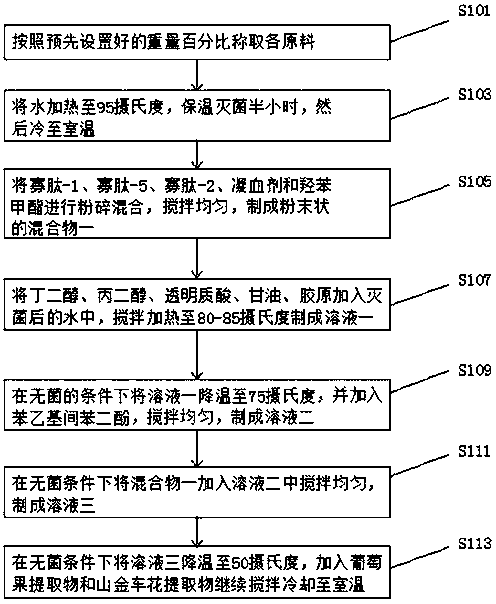

[0051] Such as figure 1 As shown, according to the embodiment of the present invention, a method for making the whitening and discoloring liquid is also provided.

[0052] Include the following steps:

[0053] Step S101, weighing each raw material according to the preset weight percentage;

[0054] Step S103, heating the water to 95 degrees Celsius, heat preservation and sterilization for half an hour, and then cool to room temperature;

[0055] Step S105, pulverizing and mixing oligopeptide-1, oligopeptide-5, oligopeptide-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com