Processing method for improving quality of purple red bud tea tree variety of black tea

A processing method and technology of tea trees, which are applied in the field of processing to improve the quality of black tea of the purple red bud tea tree variety, can solve the problems of insufficient fragrance of tea soup, heavy bitterness and astringency, and affect market expansion, so as to improve the quality of raw tea, promote degradation and transformation, and degrade with a clear effect on transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

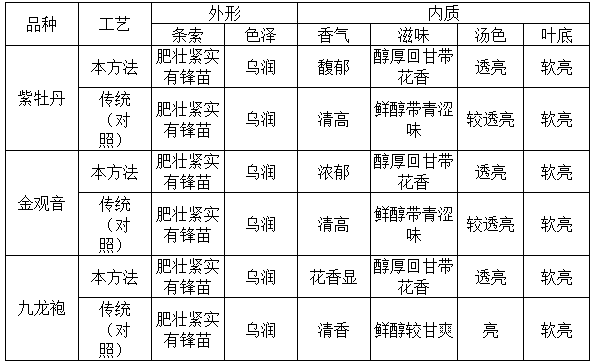

Embodiment 1

[0026] A processing method for improving the quality of black tea of a variety of purple red bud tea tree, comprising the following method steps: new shoots of one bud, two leaves and three leaves of the purple peony tea tree variety → cooling → withering → kneading → ultra-dry fermentation (environmental temperature is controlled at 35-45°C , relative humidity below 50%)→drying→picking→roasting→refined tea products.

[0027] Include the following steps:

[0028] (1) Picking fresh leaves: After the dew dries up on a sunny day, pick the first batch of young shoots with one bud and two and three leaves in spring from the purple peony tea tree variety planted in Fu’an tea area of Fujian and tea areas with similar climates as raw materials;

[0029] (2) Cooling: After the fresh leaves are returned to the field, lightly spread them evenly on a clean and transparent water sieve to cool the greens;

[0030] (3) Withering: the cool green leaves obtained in step (2) are moved into...

Embodiment 2

[0041] A processing method for improving the quality of black tea of Zihongbud tea tree variety, comprising the following method steps: new shoots of one bud, two leaves and three leaves of Jinguanyin tea tree variety → cooling → withering → kneading → ultra-dry fermentation (environmental temperature is controlled at 35-45°C , relative humidity below 50%)→drying→picking→roasting→refined tea products.

[0042] Include the following steps:

[0043] (1) Picking of fresh leaves: After the dew dries up on a sunny day, pick the first batch of young shoots with one bud and two and three leaves in spring of the Jinguanyin tea tree variety planted in Fu’an tea area of Fujian and tea areas with similar climates as raw materials;

[0044] (2) Cooling: After the fresh leaves are returned to the field, lightly spread them evenly on a clean and transparent water sieve to cool the greens;

[0045] (3) Withering: the cool green leaves obtained in step (2) are moved into an air-conditioned...

Embodiment 3

[0056] A processing method for improving the quality of black tea of Zihongbud tea tree variety, comprising the following method steps: new shoots of one bud, two leaves and three leaves of Jiulongpao tea tree variety → cooling → withering → kneading → ultra-dry fermentation (environmental temperature is controlled at 35-45°C , relative humidity below 50%)→drying→picking→roasting→refined tea products.

[0057] Include the following steps:

[0058] (1) Picking fresh leaves: After the dew dries up on a sunny day, pick the first batch of young shoots with one bud and two and three leaves in spring of the Jiulongpao tea tree variety planted in Fu’an tea area of Fujian and tea areas with similar climates as raw materials;

[0059] (2) Cooling: After the fresh leaves are returned to the field, lightly spread them evenly on a clean and transparent water sieve to cool the greens;

[0060] (3) Withering: the cool green leaves obtained in step (2) are moved into an air-conditioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com