Lithium positive electrode surface protective coating and method for preparing same

A protective coating and anode technology, applied in the field of lithium anode surface protective coating and its preparation, achieves the effects of high lithium ion conductivity, simple operation and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

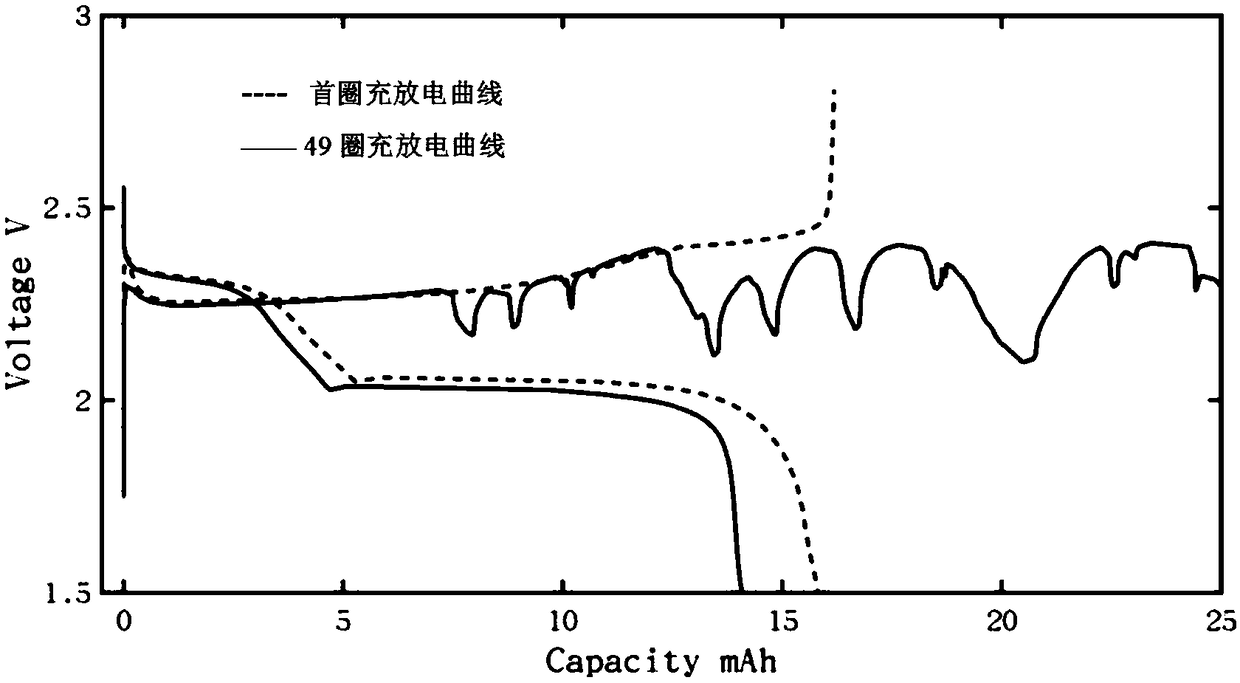

Examples

Embodiment 1

[0040] Such as figure 1 As shown, the lithium anode surface protective coating provided in this embodiment is formed by stacking nanoparticles with a particle size of 20-50 nm, and the pores between the stacked nanoparticles are filled with solid electrolyte particles; Silicon, solid electrolyte can use lithium sulfide.

[0041] The protective coating 2 is arranged between the lithium anode 1 and the separator 3 of the lithium metal battery to protect the lithium anode 1; wherein, the thickness of the protective coating 2 can be 2 μm, 10 μm, 18 μm or 30 μm.

[0042] The protective coating provided by the present embodiment can be made by the following methods:

[0043] Step 1: Take 40 parts of silica nanoparticles with a particle size of 20-50 nm, take 50 parts of elemental sulfur powder, put them into a ball mill tank, mix and ball mill for 2 hours to obtain a uniform composite material;

[0044] Step 2: Add 8 parts of polyoxyethylene binder to the ball mill tank to mix wit...

Embodiment 2

[0049] Such as figure 1 As shown, the lithium anode surface protective coating provided in this embodiment is formed by stacking nanoparticles with a particle size of 10-100 nm, and the pores between the stacked nanoparticles are filled with solid electrolyte particles; the nanoparticles are trioxide Dialuminum, lithium phosphide can be used as the solid electrolyte.

[0050] The protective coating 2 is arranged between the lithium anode 1 and the diaphragm 3 of the lithium metal battery to protect the lithium anode 1; the thickness of the protective coating 2 can be 6 μm, 9 μm, 15 μm or 45 μm.

[0051] The protective coating provided by the present embodiment can be made by the following methods:

[0052] Step 1: Take 60 parts of aluminum oxide nanoparticles with a particle size of 10-80nm, take 30 parts of simple red phosphorus powder, put them in a heater and heat for 2 hours to obtain a uniform composite material;

[0053] Step 2: Add 10 parts of polyacrylonitrile binder...

Embodiment 3

[0058] Such as figure 1 As shown, the lithium anode surface protective coating provided in this embodiment is formed by stacking nanoparticles with a particle size of 100-150 nm, and the pores between the stacked nanoparticles are filled with solid electrolyte particles; Silicon, solid electrolyte can use lithium nitride.

[0059] The protective coating 2 is arranged between the lithium anode 1 and the separator 3 of the lithium metal battery to protect the lithium anode 1; the thickness of the protective coating 2 can be 50 μm, 75 μm, 90 μm or 100 μm.

[0060] The protective coating provided by the present embodiment can be made by the following methods:

[0061] Step 1: Take 60 parts of silicon dioxide nanoparticles with a particle size of 100-150nm, take 60 parts of copper nitride powder, put them into a ball mill tank and heat for 2 hours to obtain a uniform composite material;

[0062] Step 2: Add 10 parts of polyvinylidene fluoride binder to the ball mill tank to mix w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com