Non-setting adhesive marking machine continuous work control method and device based on digital printing information

A digital printing and scribing machine technology, applied in the direction of collaborative operation device, printing device, printing, etc., can solve the problems of label waste, human error, defective label products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

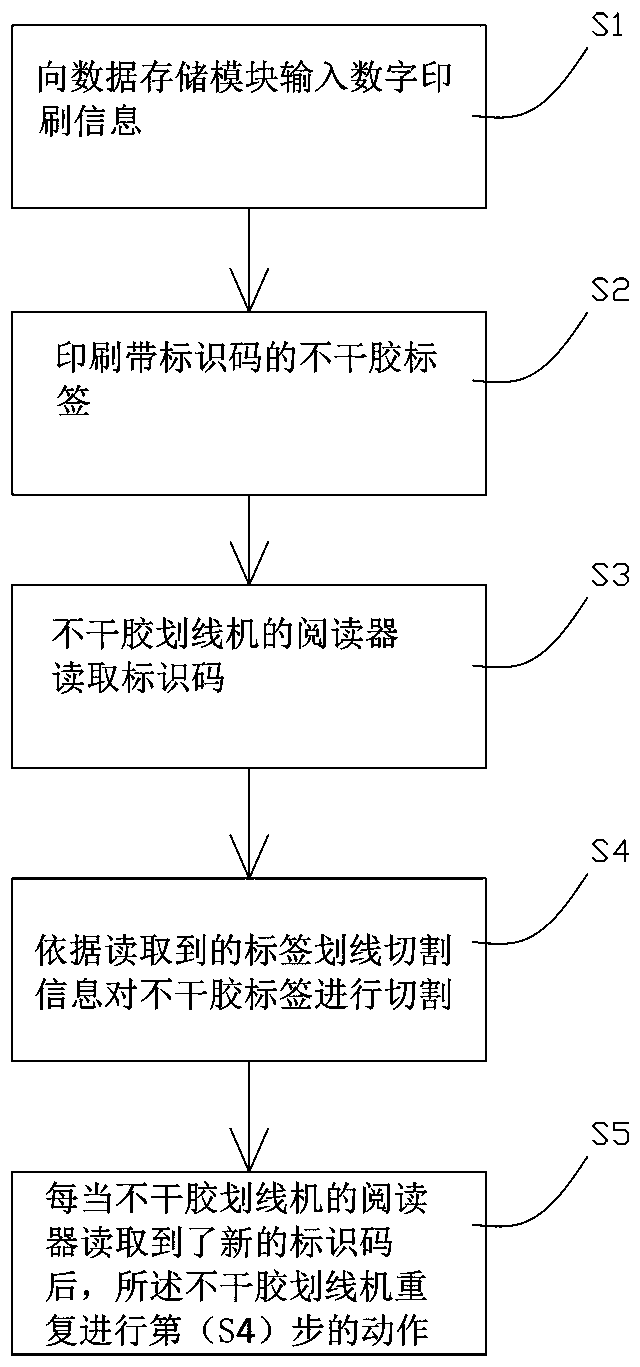

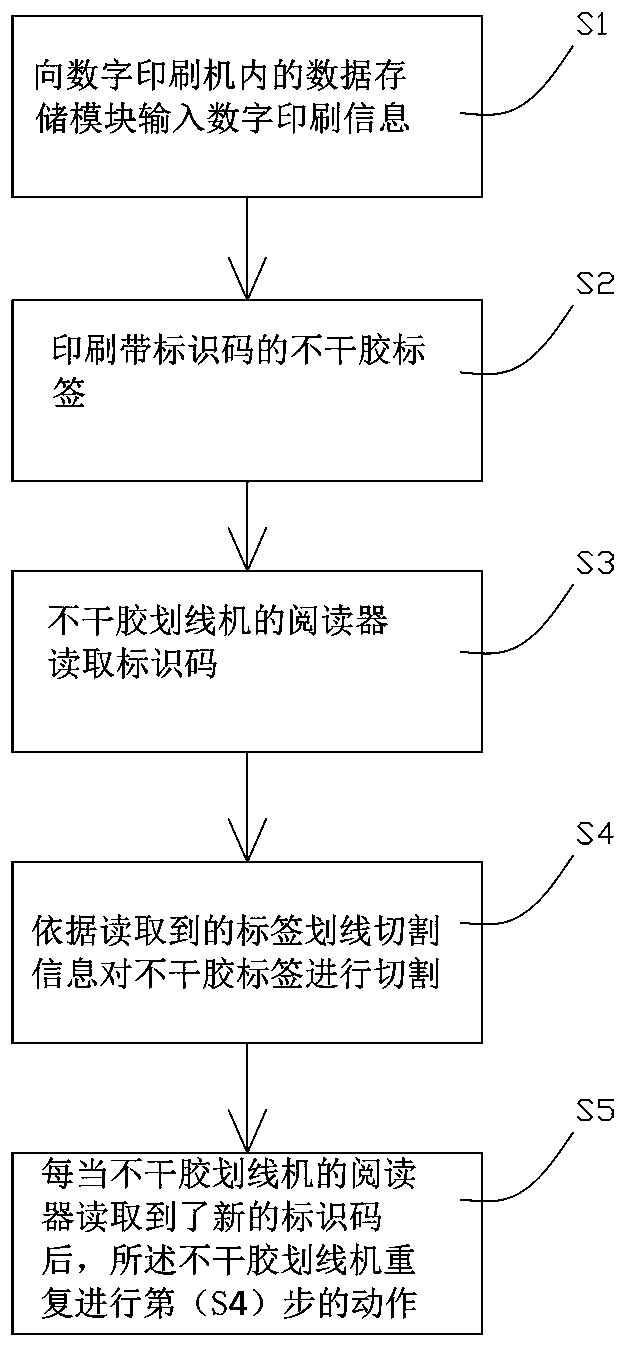

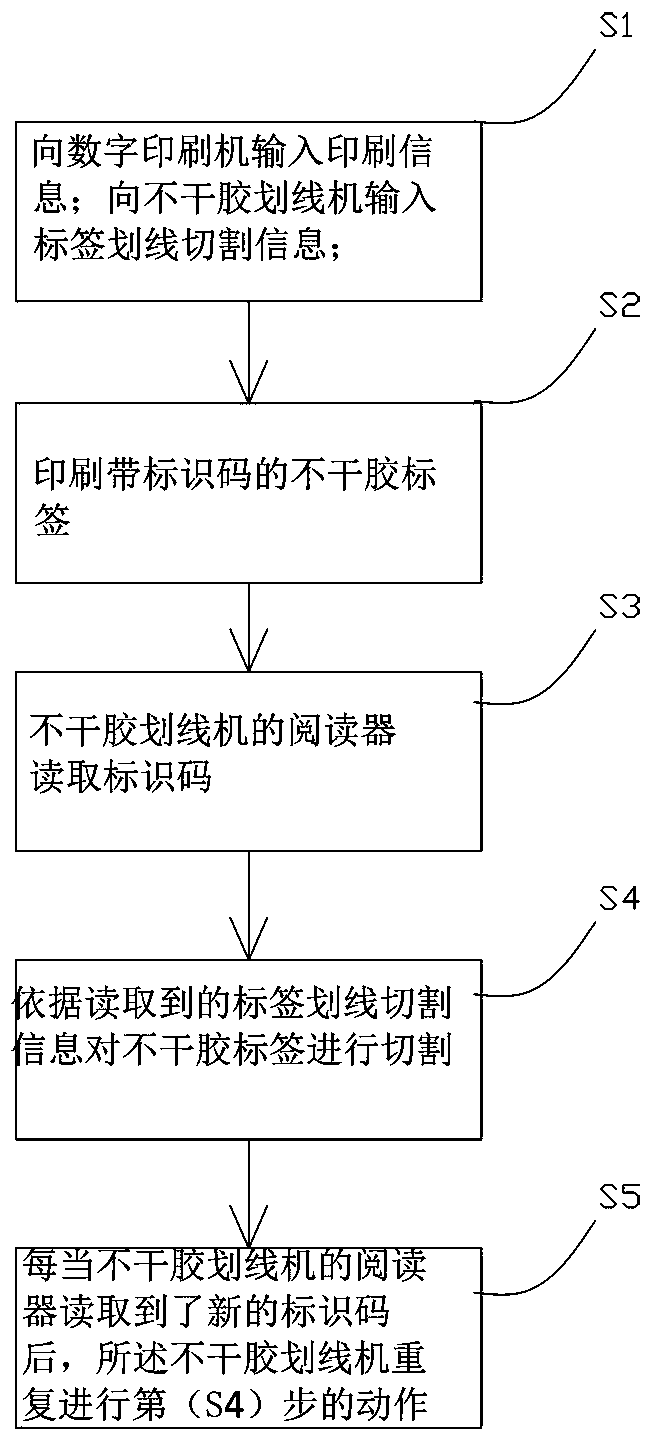

[0038] See figure 2 , figure 2 Disclosed is a second implementation of the method for controlling the continuous operation of the self-adhesive scribing machine based on digital printing information. In this embodiment, the data storage module and the control module of the digital printing machine are combined into one. Including the following steps:

[0039] S1. Input digital printing information to the control module of the digital printing machine, wherein the digital printing information includes printing information for printing self-adhesive labels and label scribing and cutting information for cutting self-adhesive labels;

[0040] S2. The digital printing machine prints the self-adhesive label according to the printing information, and at least prints the identification code with the label type information at the predetermined position of the first self-adhesive label;

[0041] S3. After the reader of the self-adhesive marking machine reads the identification code,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com