Construction method for long-span handle-basket arch bridge steel arch rib fastening and hanging system in high speed railway

A technology for high-speed railways and construction methods, applied to arch bridges, bridges, bridge parts, etc., can solve the problems of large-span arch bridge construction line shape control difficulty, auxiliary support erection difficulties, etc., to reduce the input of auxiliary materials, save the overall construction period, save The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

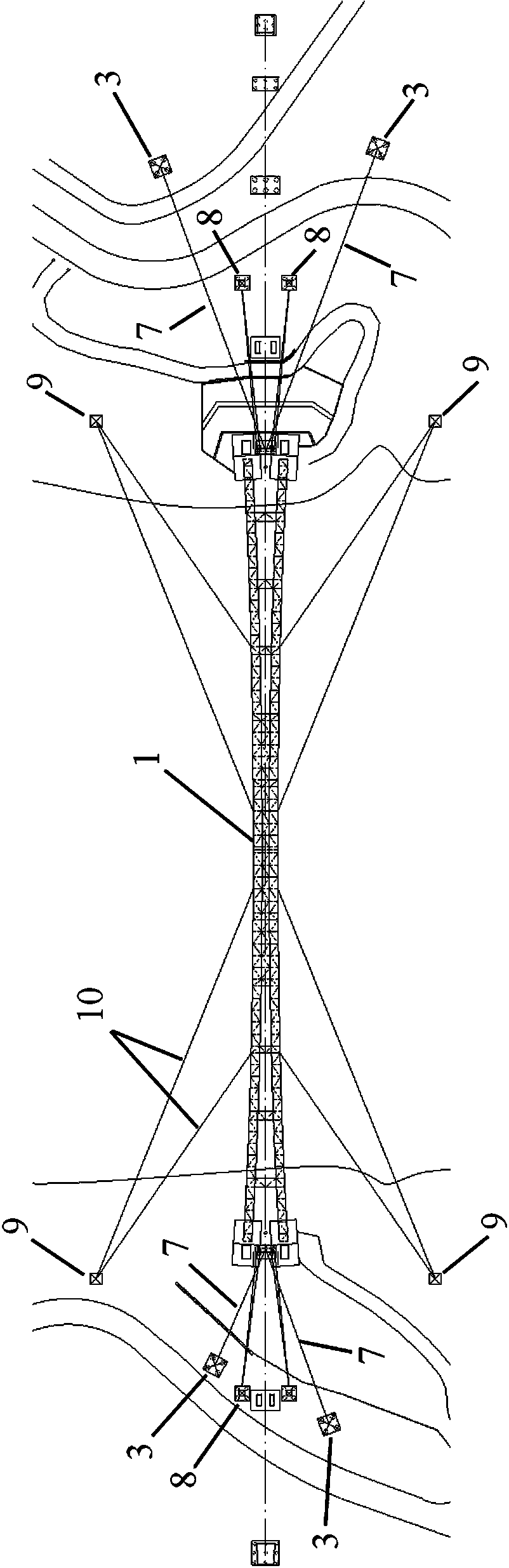

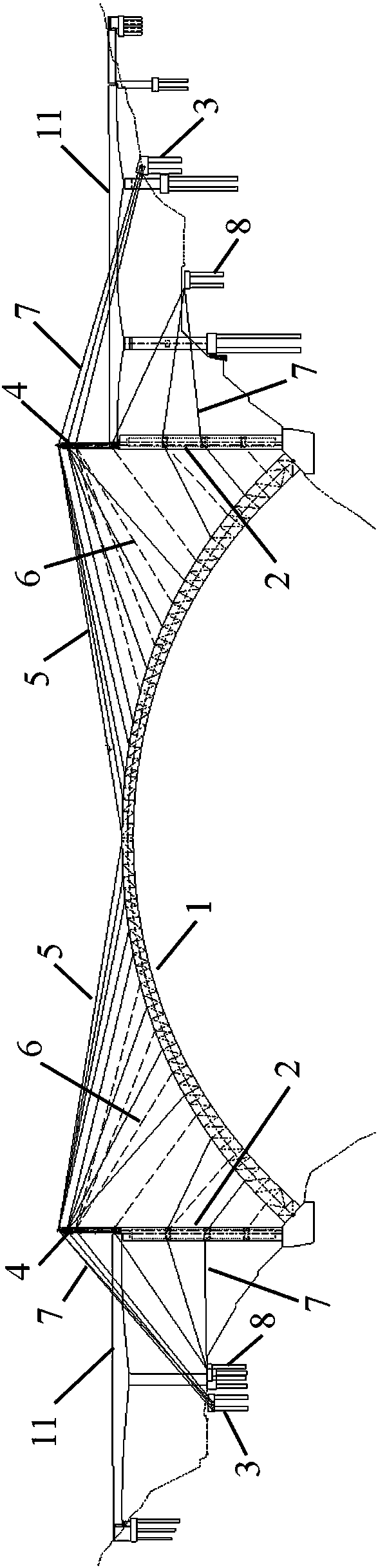

[0038] see Figure 1 to Figure 6 , arrange buckle tower 4 on the partial main bridge side of cross-strait junction pier 2 pier top, arrange anchor cable anchorage 3, cable tower foundation 8 and crosswind cable anchorage 9, buckle tower 4 on the hillside on both banks and behind the arch foot A three-layer tensioning platform 12 is arranged on the top, and anchor holes 13 are arranged on the tensioning platform 12 .

[0039] The main temporary facilities such as the anchor cable anchorage 3 and the buckle tower 4 are reasonably arranged after accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com