Thermosensitive CTP plate production technology

A production process, heat-sensitive technology, applied in the field of printing plates, can solve the problems of CTP plate dot reproducibility, photosensitive development characteristics, poor printing force, oxide film compactness, poor thickness and porosity, etc., to achieve Improve dot reproducibility and printing durability, improve storage performance and printing durability, and prevent staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

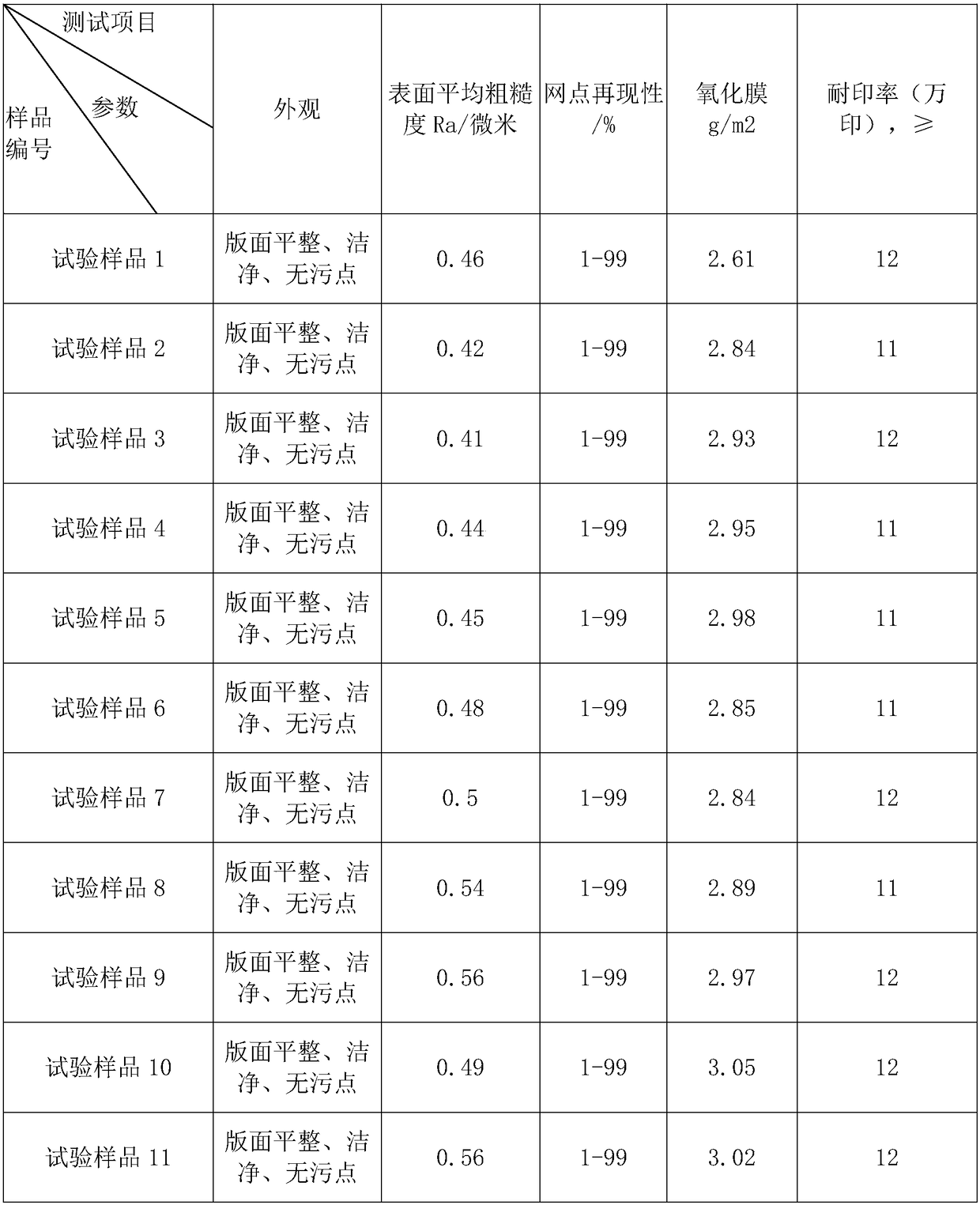

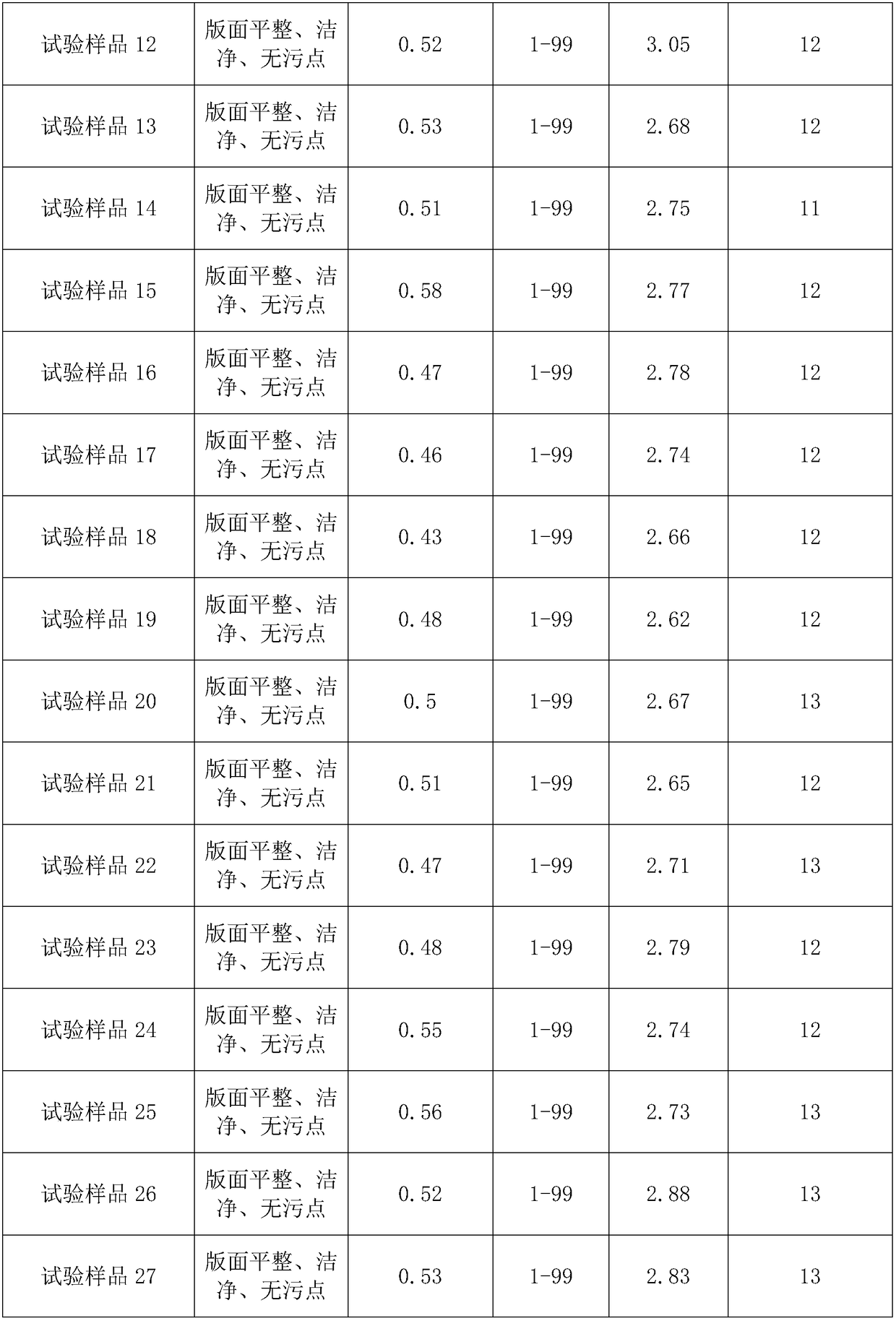

Embodiment 1

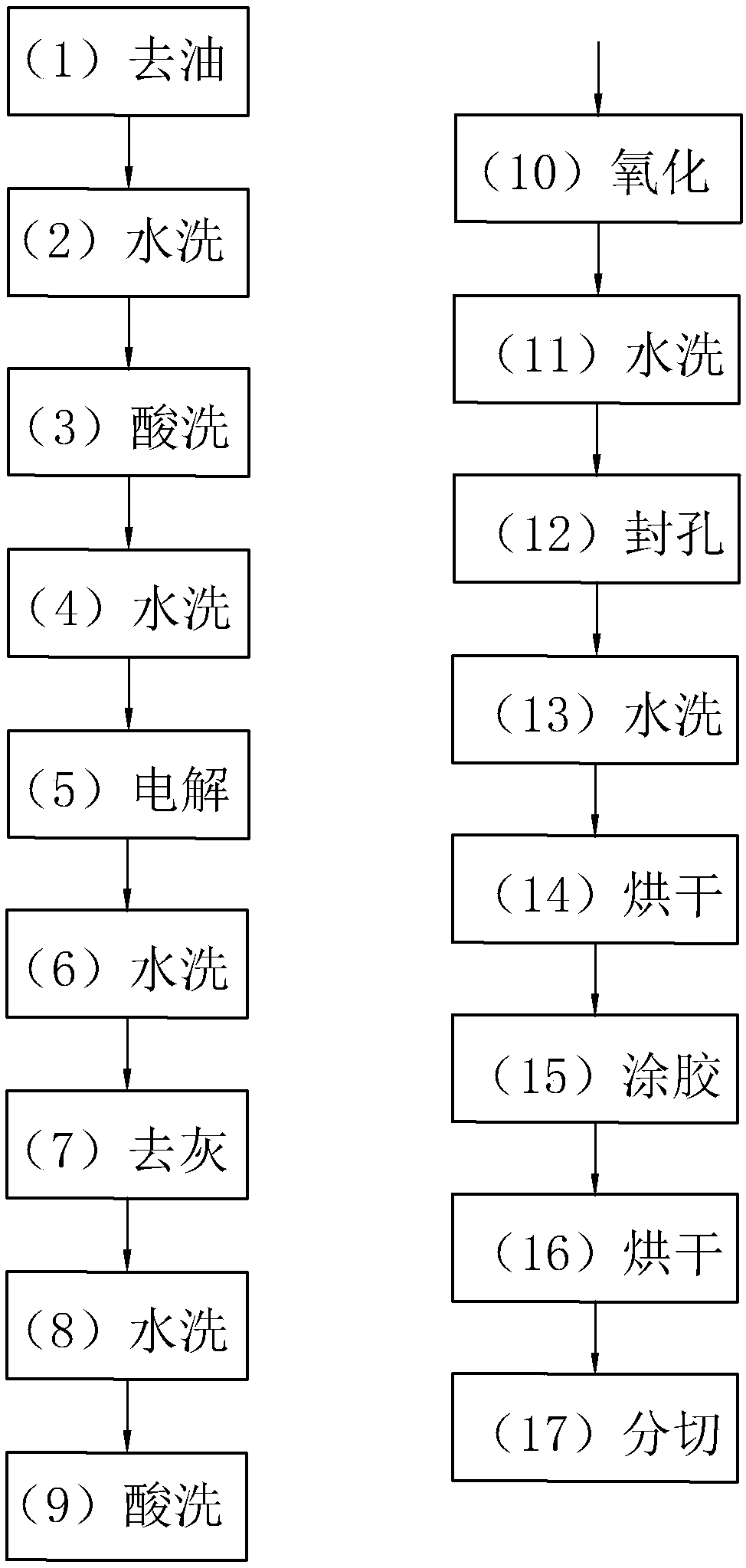

[0046] Example 1: Such as figure 1 As shown, a heat-sensitive CTP plate production process is prepared through the following steps:

[0047] (1) Degreasing: mix sodium hydroxide, sodium phosphate, corrosion inhibitor and water into a solution in proportion, and spray the aluminum substrate to remove oil, sodium hydroxide, sodium phosphate, and corrosion inhibitor in parts by weight The ratio is 2:1:1, the solution concentration is 40g / L, the solution temperature is 56°C, and the oil removal time is 15s;

[0048] (2) Washing: Use pure water at room temperature to spray the degreasing aluminum plate substrate with water for 6s;

[0049] (3) Pickling: The sulfuric acid is configured as an aqueous solution with a mass concentration of 80g / L, and the aluminum plate substrate after washing is sprayed and pickled, and the pickling time is 6s;

[0050] (4) Washing: Use pure water at room temperature to spray the acid-washed aluminum substrate with water for 6 seconds;

[0051] (5) Electrolysi...

Embodiment 2

[0065] Embodiment 2: A heat-sensitive CTP plate production process, which is different from Embodiment 1 in that the concentration of the solution in step (1) is 42 g / L.

Embodiment 3

[0066] Embodiment 3: A heat-sensitive CTP plate production process, which is different from Embodiment 1 in that the concentration of the solution in step (1) is 45 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com