Step-by-step dewatering method for biomass pyrolysis liquid hydrogenation combined device

A combined device and pyrolysis liquid technology, used in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of narrow adaptability, easy pollution and damage, and high relative energy consumption, so as to improve product quality and economy. Benefit, the effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail by Embodiment 1 below. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Adjustment still belongs to the protection scope of the present invention.

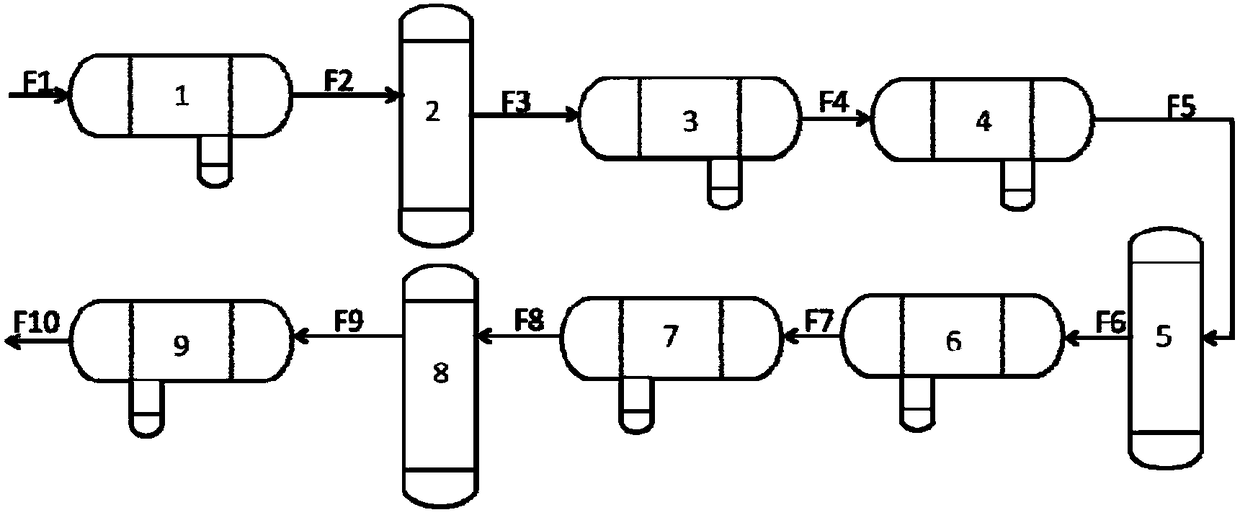

[0048] An energy company's 30,000 tons / year biomass pyrolysis liquid hydrogenation combined pilot plant, consisting of biomass pyrolysis liquid hydrodeoxygenation unit (BDO unit), biomass pyrolysis liquid hydrocracking unit (OTM unit) and bio-oil The separation unit (COU unit) is combined. The main function of the combined unit is to process the raw material of biomass pyrolysis liquid through hydrodeoxygenation process and hydrocracking process, and finally produce common fossil fuels such as light diesel oil, heavy diesel oil and naphtha. product. However, during the operation of the device, it was found that the water content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com