Pipe casting method based on stainless steel and carbon steel bimetallic mixed solution

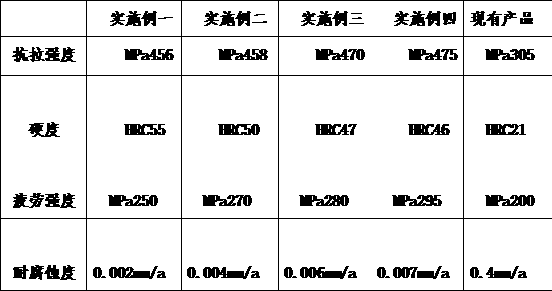

A casting method, stainless steel technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of rust hardness and other problems, achieve the effects of not easy to deform and bend, improve practicability, and good fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A pipe casting method based on a stainless steel and carbon steel bimetallic liquid mixture, the manufacturing method comprising the following steps:

[0029] S1, weigh stainless steel according to the weight percentage (its composition is C: 0.12%, Si: 0.74%, Mn: 0.90%, S: 0.025%, P: 0.030%, Cr: 16.00%, Ni: allowed to contain 0.55%, the remaining The amount is iron) and carbon steel raw materials (its composition is C: 0.22%, Si: 0.15%, Mn: 0.3%, P: 0.025%, S: 0.025%, the balance is iron), stainless steel raw materials and carbon steel Raw material ratio is 2:1;

[0030] S2, putting the stainless steel raw material and carbon steel raw material weighed in step S1 into two melting and casting furnaces to be melted and cast into casting liquid respectively, and the vacuum degree in the vacuum melting furnace is 1Pa, for standby;

[0031] S3, raising the temperature of the centrifuge mold to 300°C, then injecting the stainless steel casting liquid and carbon steel castin...

Embodiment 2

[0035] A pipe casting method based on a stainless steel and carbon steel bimetallic liquid mixture, the manufacturing method comprising the following steps:

[0036] S1, weigh stainless steel according to the weight percentage (its composition is C: 0.12%, Si: 0.73%, Mn: 0.80%, S: 0.024%, P: 0.029%, Cr: 16.60%, Ni: allowed to contain 0.40%, the remaining The amount is iron) and carbon steel raw materials (its composition is C: 0.24%, Si: 0.17%, Mn: 0.36%, P: 0.24%, S: 0.24%, the balance is iron), stainless steel raw materials and carbon steel Raw material ratio is 2:1;

[0037] S2, putting the stainless steel raw material and carbon steel raw material weighed in step S1 into two casting furnaces to be melted and cast into a casting liquid respectively, and the vacuum degree in the vacuum melting furnace is 1.1Pa, for standby;

[0038] S3, raising the temperature of the centrifuge mold to 320°C, then injecting the stainless steel casting liquid and carbon steel casting liquid ...

Embodiment 3

[0042] A pipe casting method based on a stainless steel and carbon steel bimetallic liquid mixture, the manufacturing method comprising the following steps:

[0043] S1, weigh stainless steel according to the weight percentage (its composition is C: 0.12%, Si: 0.70%, Mn: 0.70%, S: 0.023%, P: 0.028%, Cr: 16.70%, Ni: allowed to contain 0.30%, the remaining The amount is iron) and carbon steel raw materials (its composition is C: 0.25%, Si: 0.18%, Mn: 0.37%, P: 0.25%, S: 0.25%, the balance is iron), stainless steel raw materials and carbon steel Raw material ratio is 2:1;

[0044] S2, putting the stainless steel raw material and carbon steel raw material weighed in the step S1 into two casting furnaces to be melted and cast into a casting liquid respectively, and the vacuum degree in the vacuum melting furnace is 1.2Pa, for standby;

[0045] S3, raising the temperature of the centrifuge mold to 330°C, then injecting the stainless steel casting liquid and carbon steel casting liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com