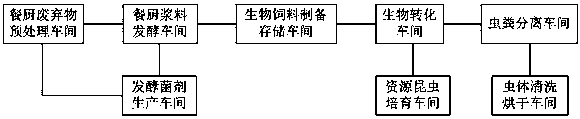

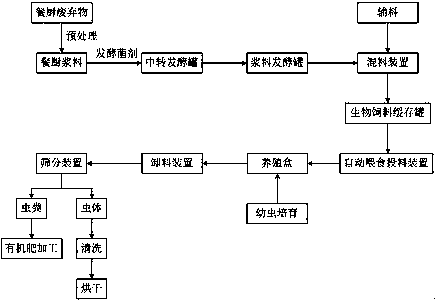

Kitchen waste resource utilization and non-pollution treatment system and method

A kitchen waste and treatment system technology, which is applied in the field of kitchen waste resource utilization and pollution-free treatment system, can solve the problems of high processing difficulty, low efficiency, and reduced calorific value, and achieves low cost, high efficiency, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For the convenience of description, the "left", "right", "upper" and "lower" referred to hereinafter are consistent with the directions of "left", "right", "upper" and "lower" of the accompanying drawings of the present invention. It should be noted that, under the condition that the technical solutions do not conflict or contradict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0050] The term “kitchen waste” in this embodiment refers to the waste generated by units and individuals engaged in catering services, unit meals, food production and processing (hereinafter collectively referred to as catering enterprises, or units that produce kitchen waste) in the process of production and operation. Garbage such as food residues, food processing waste, waste edible oils and fats (including inedible animal and vegetable oils and various oil-water mixtures) generated in the environment. The types of kitchen was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com