Device for receiving substrates in pairs

A technology for equipment and substrates, used in gaseous chemical plating, coatings, electrical components, etc., can solve problems such as unavailability, and achieve the effects of reducing thermal mass, reducing production costs, and improving temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

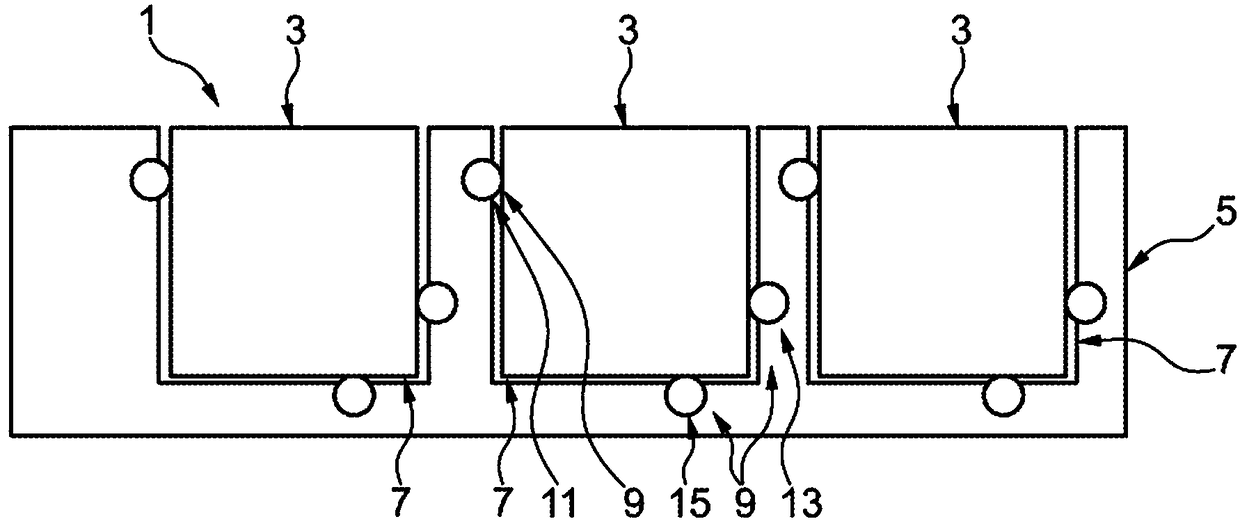

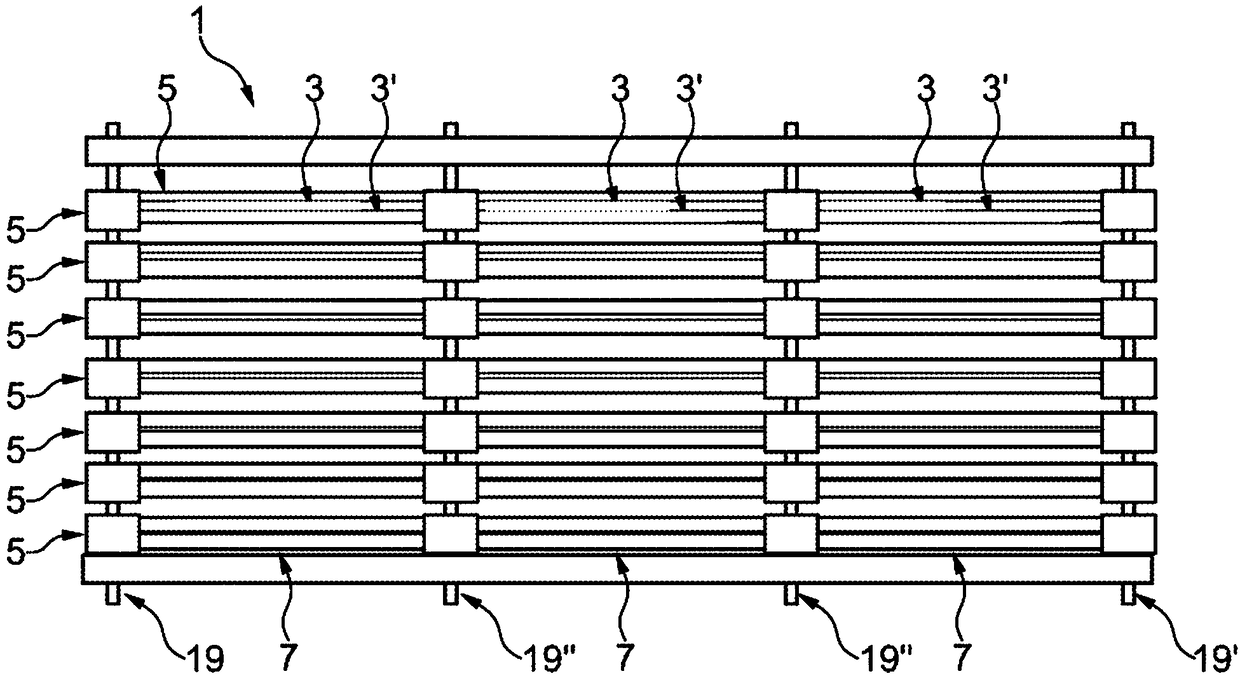

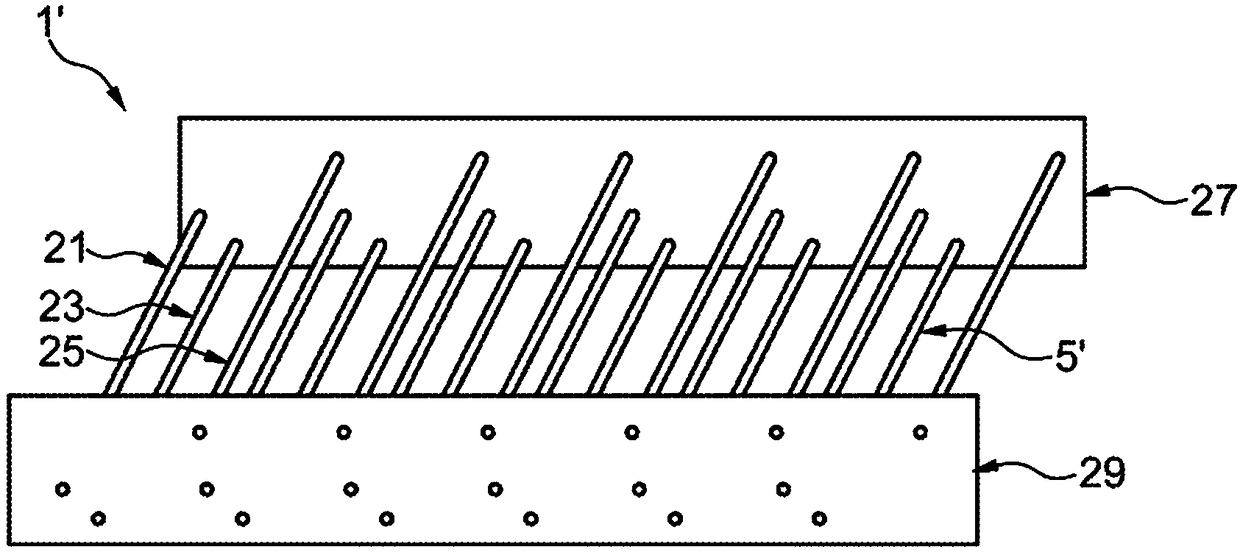

[0049] exist figure 1 with figure 2 A first embodiment of the device according to the invention in the form of a plasma boat 1 for receiving sheet-like substrates 3 is shown in . A substrate 3 can be processed by means of a plasma boat 1 in a processing device (not shown), in particular a plasma CVD system (PECVD). In this case, the plasma boat 1 includes a holding device 5 for holding and fixing a substrate 3 in a holding area 7 .

[0050] In this case, two substrates 3, 3' are arranged in each receiving area 7, the rear side of the first substrate 3 directly abutting the rear side of the second substrate 3'. The receptacle 5 and the receptacle region 7 consist of or include an electrically conductive, refractory material, in this example graphite, which is inert to the process gas used in the PECVD system.

[0051] As shown, the accommodation area 7 of the accommodation device 5 is formed U-shaped and is designed and configured to accommodate two substrates 3, 3' arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com