Slurry mixing and stirring equipment for battery pole piece processing

A technology of mixing and stirring and battery pole pieces, which is applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve problems such as unevenness, adhesion to slurry mixing, and influence of slurry coating, etc., to achieve The structure of the equipment is simple and the effect of avoiding the increase of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

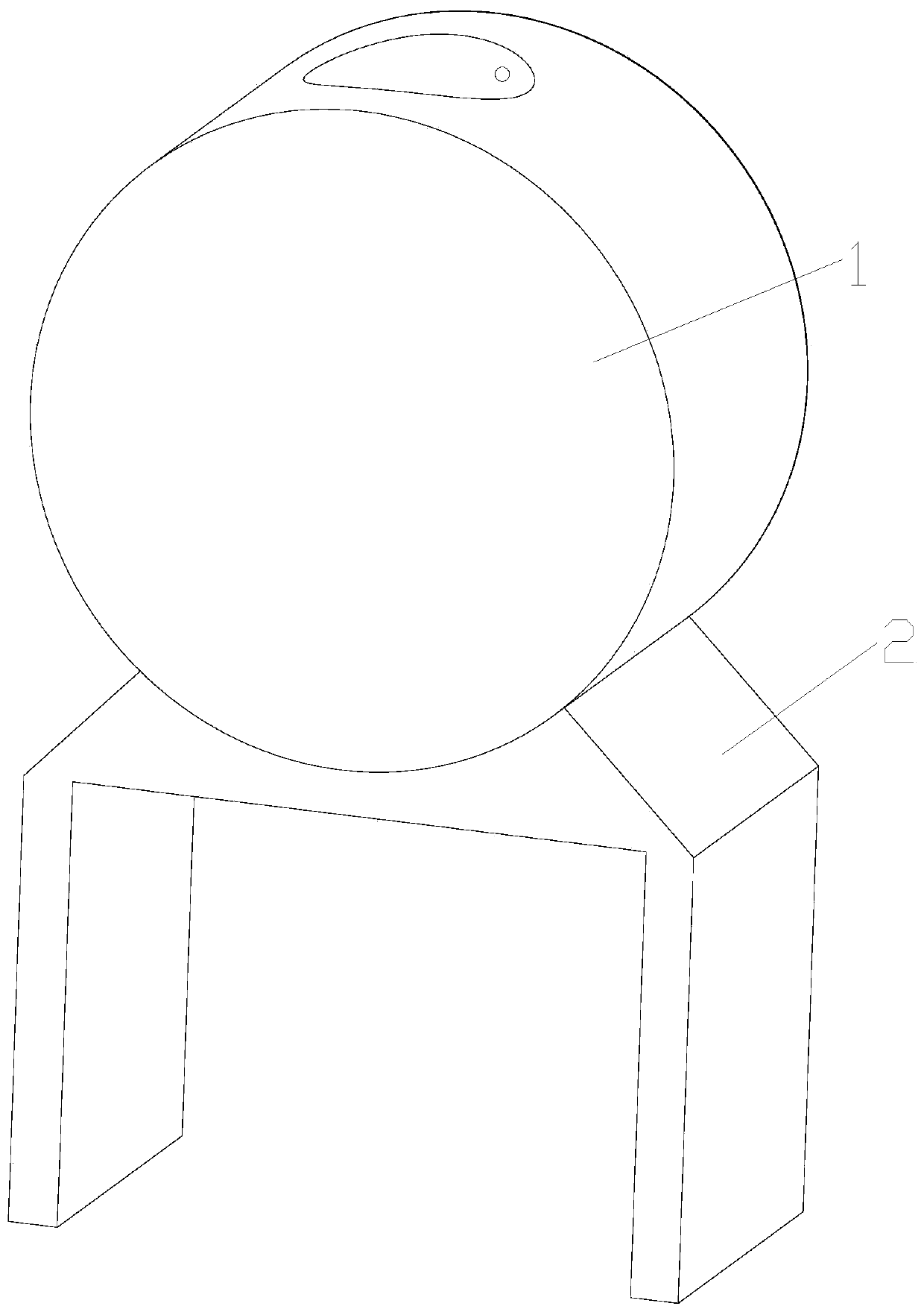

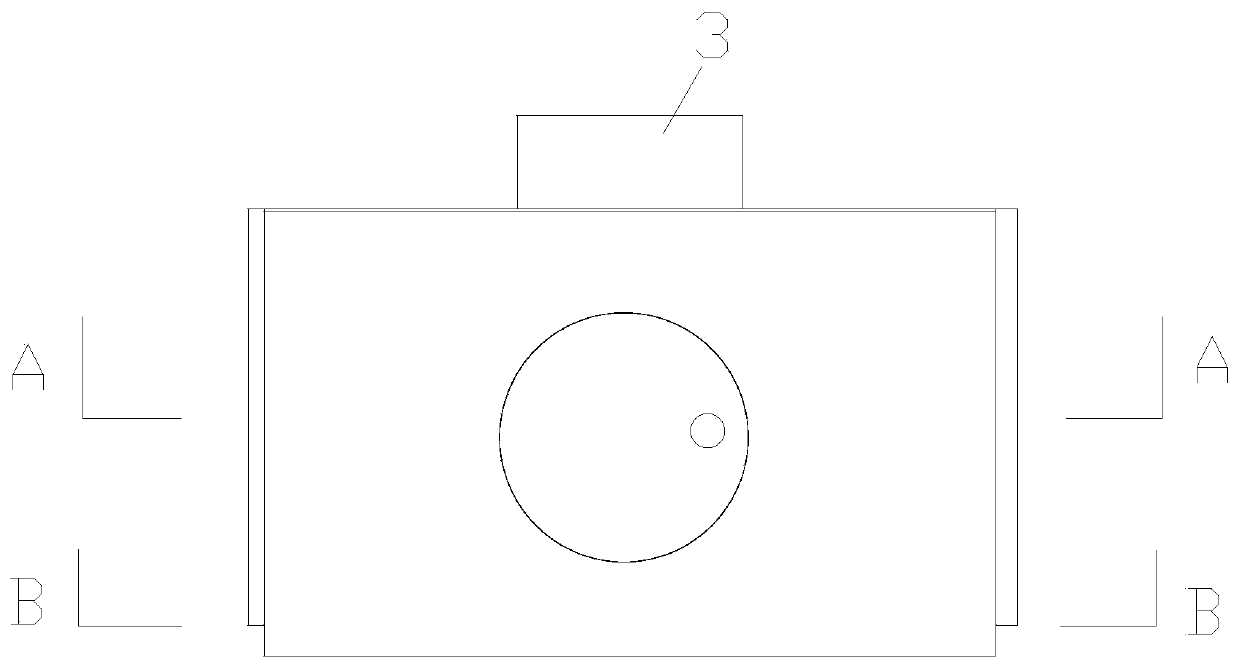

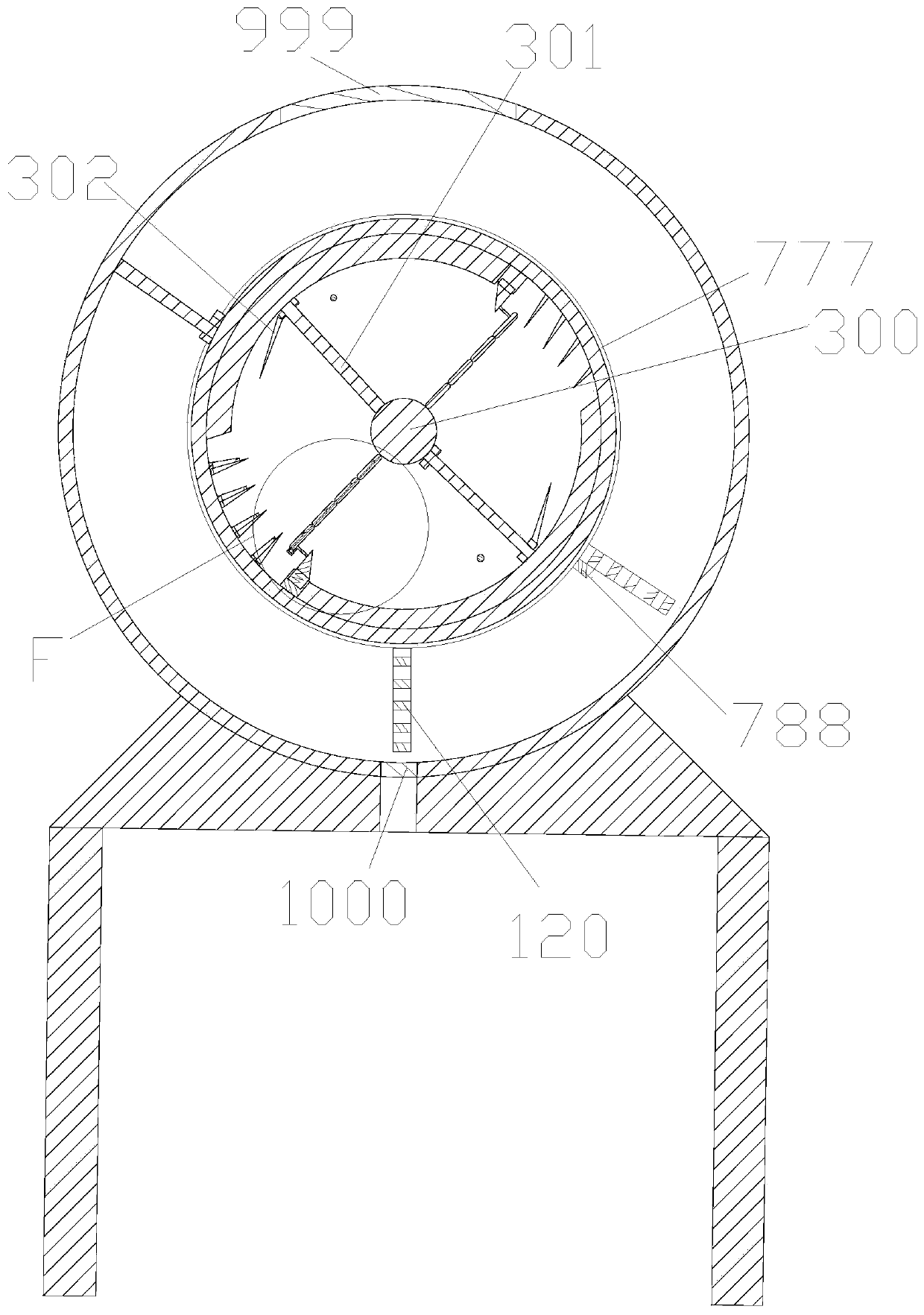

[0021] Such as Figure 1-11 As shown, a slurry mixing and stirring equipment for battery pole piece processing includes a fixed housing 1, a fixed space arranged in the fixed housing 1, a support seat 2 fixedly arranged on the lower end surface of the fixed housing 1, a fixed The motor 3 arranged on the rear end surface of the fixed housing 1, the installation groove arranged on the rear end wall of the fixed space, the transmission shaft fixedly arranged on the output end of the motor 3 and located in the installation groove, and the stirring device arranged on the transmission shaft; The stirring device includes a rotating housing 4 fixedly arranged on the transmission shaft, a rotating space 5 arranged on the end surface of the rotating housing 4, and two scraping members evenly distributed on the inner wall of the rotating space in the circumferential direction.

[0022] The scraping member includes a groove arranged on the rotating space 5, a plurality of rotating plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com