Vacuum processing device

The technology of a vacuum processing device and a vacuum tank is applied in the directions of vacuum evaporation coating, transportation and packaging, ion implantation coating, etc. , the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

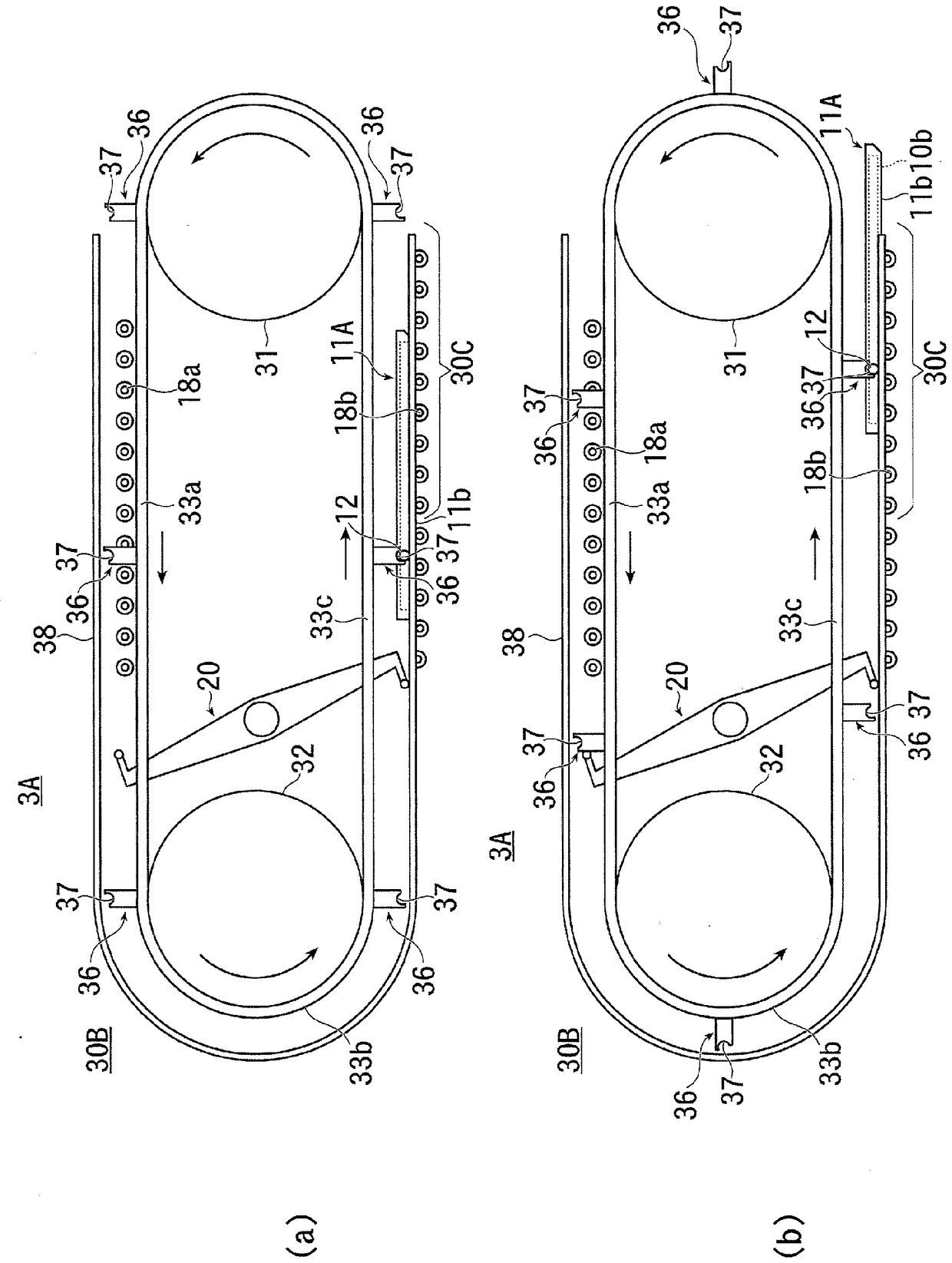

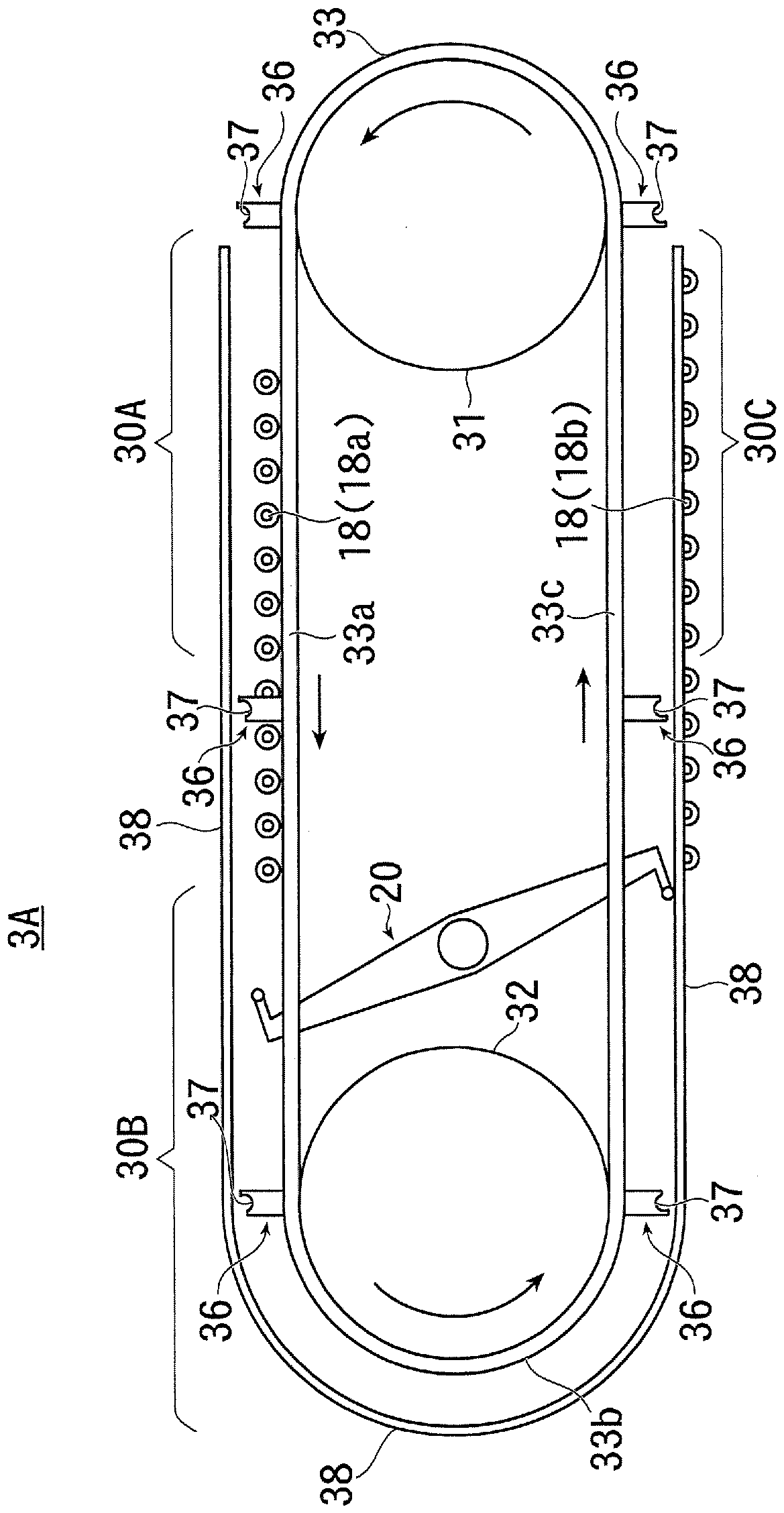

[0062] Embodiments of the present invention will be described in detail below with reference to the drawings.

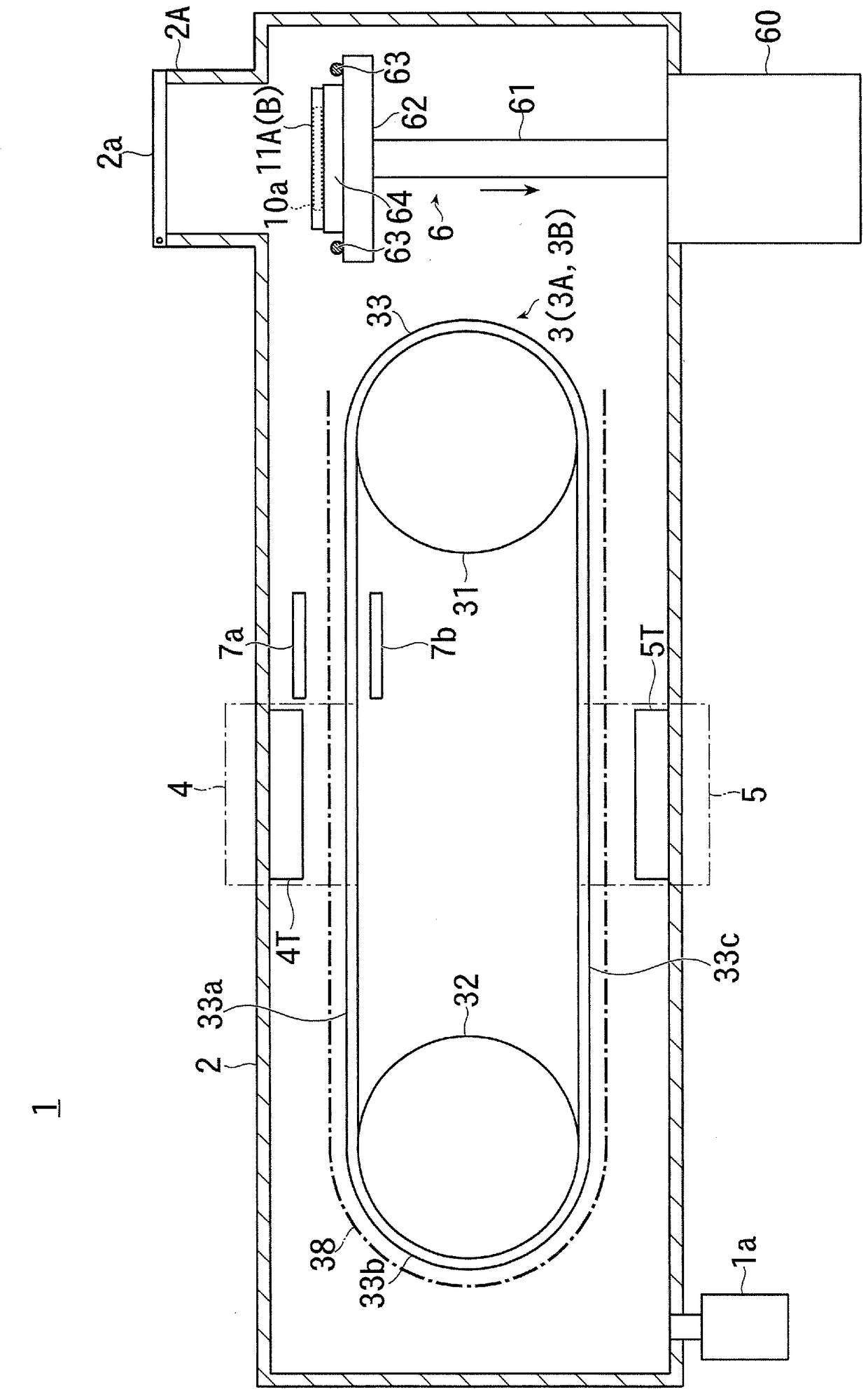

[0063] figure 1 It is a schematic configuration diagram showing the whole of an embodiment of the vacuum processing apparatus according to the present invention.

[0064] Such as figure 1 As shown, the vacuum processing apparatus 1 of this embodiment has the vacuum tank 2 which is connected to the vacuum exhaust device 1a and forms a single vacuum atmosphere.

[0065] Inside the vacuum chamber 2 is provided a substrate holder transport mechanism 3 for transporting a substrate holder 11 to be described later along a transport path.

[0066] The substrate holder transport mechanism 3 is configured to continuously transport a plurality of substrate holders 11 holding the substrate 10 via, for example, trays.

[0067] Here, the detailed structure of the substrate holder conveying mechanism 3 will be described later. The substrate holder conveying mechanism 3 has, for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com