Semi-solid flow battery with ion-embedded solid negative electrode

An ion intercalation and semi-liquid flow technology, applied in the field of electrochemistry, can solve problems such as unsatisfactory performance, capacity attenuation, and limited system power density, and achieve no risk of fire and explosion, high power energy density, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

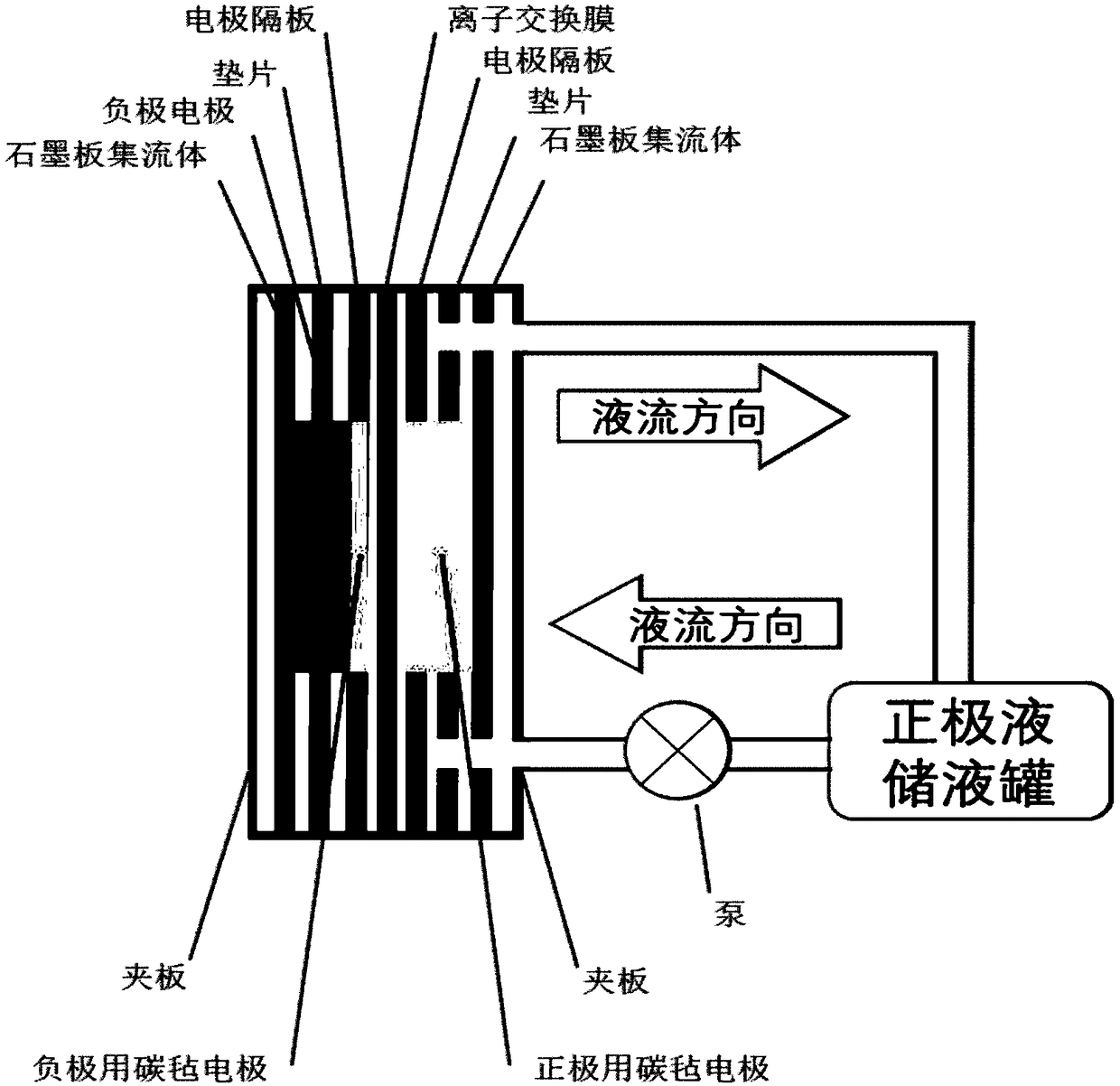

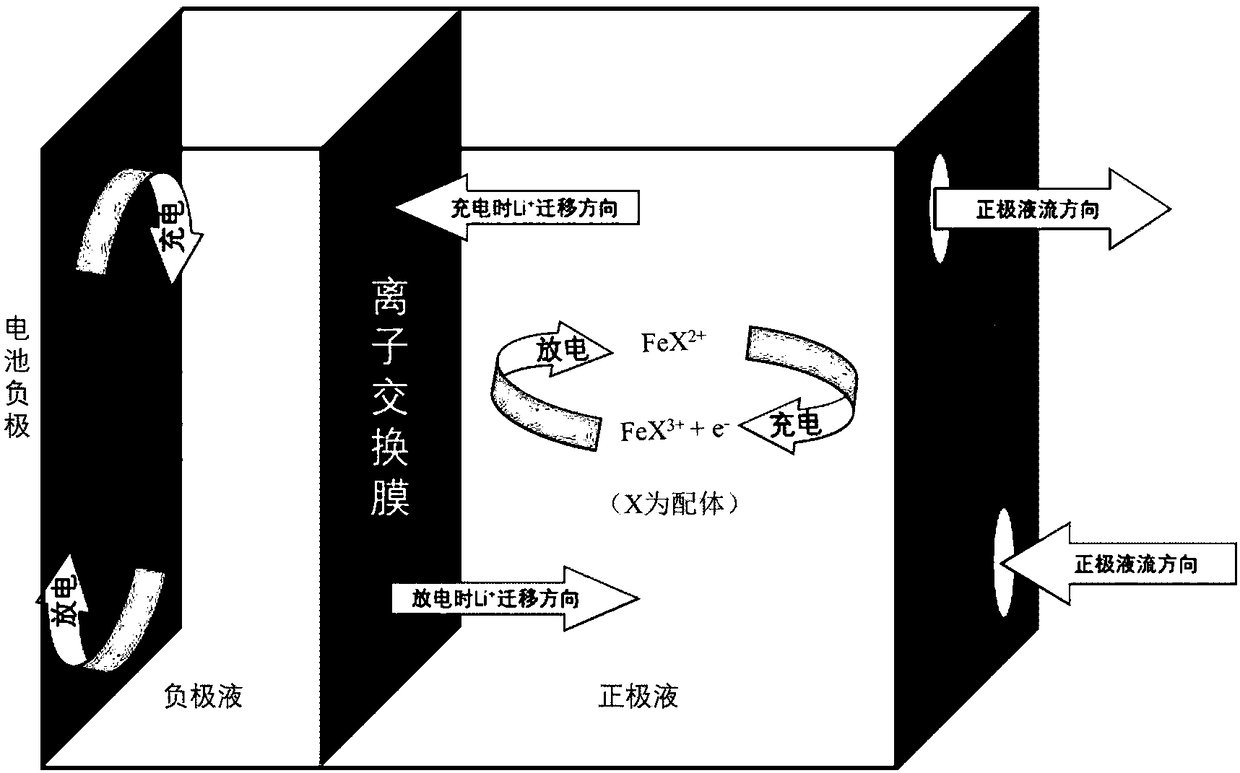

[0034] Example 1: A semi-fluid flow battery based on a sodium titanium phosphate negative electrode and an iron-glycine complex, and the positive and negative electrolytes are sodium sulfate.

[0035] In this example, 2 mol / L iron-glycine solution (10 mL) was used for the positive electrode, and 2.0 mol / L Na 2 SO 4 . The diaphragm is Nafion 115 membrane. The negative electrode is carbon-coated sodium titanium phosphate, and the negative electrode film is prepared as follows: According to the mass ratio of active material (sodium titanium phosphate): conductive agent (carbon nanotubes): binder (polytetrafluoroethylene) is 8:1:1 After mixing, it is rolled into a uniform film, and after drying, it is cut into electrodes with a size of 3 cm*3.5 cm, and is evenly pressed with a titanium mesh collector in a sandwich structure, so that the thickness of the final finished electrode is about 0.5 mm, and the active material is charged. Loaded at 400 mg cm -2 about. at 40 mA cm -2 ...

Embodiment 2

[0036] Example 2: A semi-fluid flow battery based on a sodium titanium phosphate negative electrode and an iron-glycine complex, and the positive and negative electrolytes are sodium sulfate.

[0037] In this example, 1 mol / L iron-glycine solution (20 mL) was used for the positive electrode, and 2.0 mol / L Na 2 SO 4 . The diaphragm is Nafion 115 membrane. The negative electrode is carbon-coated sodium titanium phosphate, and the negative electrode film is prepared as follows: According to the mass ratio of active material (sodium titanium phosphate): conductive agent (carbon nanotubes): binder (polytetrafluoroethylene) is 8:1:1 After mixing, it is rolled into a uniform film, and after drying, it is cut into electrodes with a size of 3 cm*3.5 cm, and is evenly pressed with a titanium mesh collector in a sandwich structure, so that the thickness of the final finished electrode is about 0.5 mm, and the active material is charged. Loaded at 400 mg cm -2 about. at 40 mA cm -2 ...

Embodiment 3

[0038] Embodiment 3: A semi-fluid flow battery based on a lithium titanium phosphate negative electrode and an iron-glycine complex, and the positive and negative electrolytes are lithium sulfate.

[0039] In this example, 2 mol / L iron-glycine solution (10 mL) was used for the positive electrode, and 2.0 mol / LLi 2 SO 4 . The diaphragm is Nafion 115 membrane. The negative electrode is carbon-coated lithium titanium phosphate, and the negative electrode film is prepared as follows: according to the mass ratio of active material (lithium titanium phosphate): conductive agent (carbon nanotubes): binder (polytetrafluoroethylene) is 8:1:1 After mixing, it is rolled into a uniform film, and after drying, it is cut into electrodes with a size of 3 cm*3.5 cm, and is evenly pressed with a titanium mesh collector in a sandwich structure, so that the thickness of the final finished electrode is about 0.5 mm, and the active material is charged. Loaded at 400 mg cm -2 about. at 40 mA c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com