Crack extraction method based on iterative phase consistency and application

An extraction method and consistent technology, applied in image data processing, instruments, calculations, etc., can solve problems such as slow calculation speed, difficulty in selecting image thresholds, difficulty in meeting real-time application requirements, etc., and achieve small calculation and extraction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A crack extraction method based on iterative phase consistency, the specific steps are as follows:

[0056] ⑴Combine morphological operations and denoising algorithms to preprocess CT images to reduce the influence of background and noise on images;

[0057] (2) Perform polar coordinate transformation on the preprocessed image to obtain the image PolarImg;

[0058] (3) iteratively calculate the phase consistency of the image PolarImg in the polar coordinate system, and enhance the image;

[0059] (4) Perform polar coordinate inverse transformation on the enhanced image;

[0060] (5) According to the unimodal thresholding algorithm, the threshold value of the enhanced image is automatically selected, and then the enhanced image is segmented by 1.5 times of the threshold value to obtain the cracks in the image.

[0061] Preferably, the specific steps of said step (1) are as follows:

[0062] Use the non-local mean algorithm to denoise the original CT image;

[0063] U...

Embodiment 2

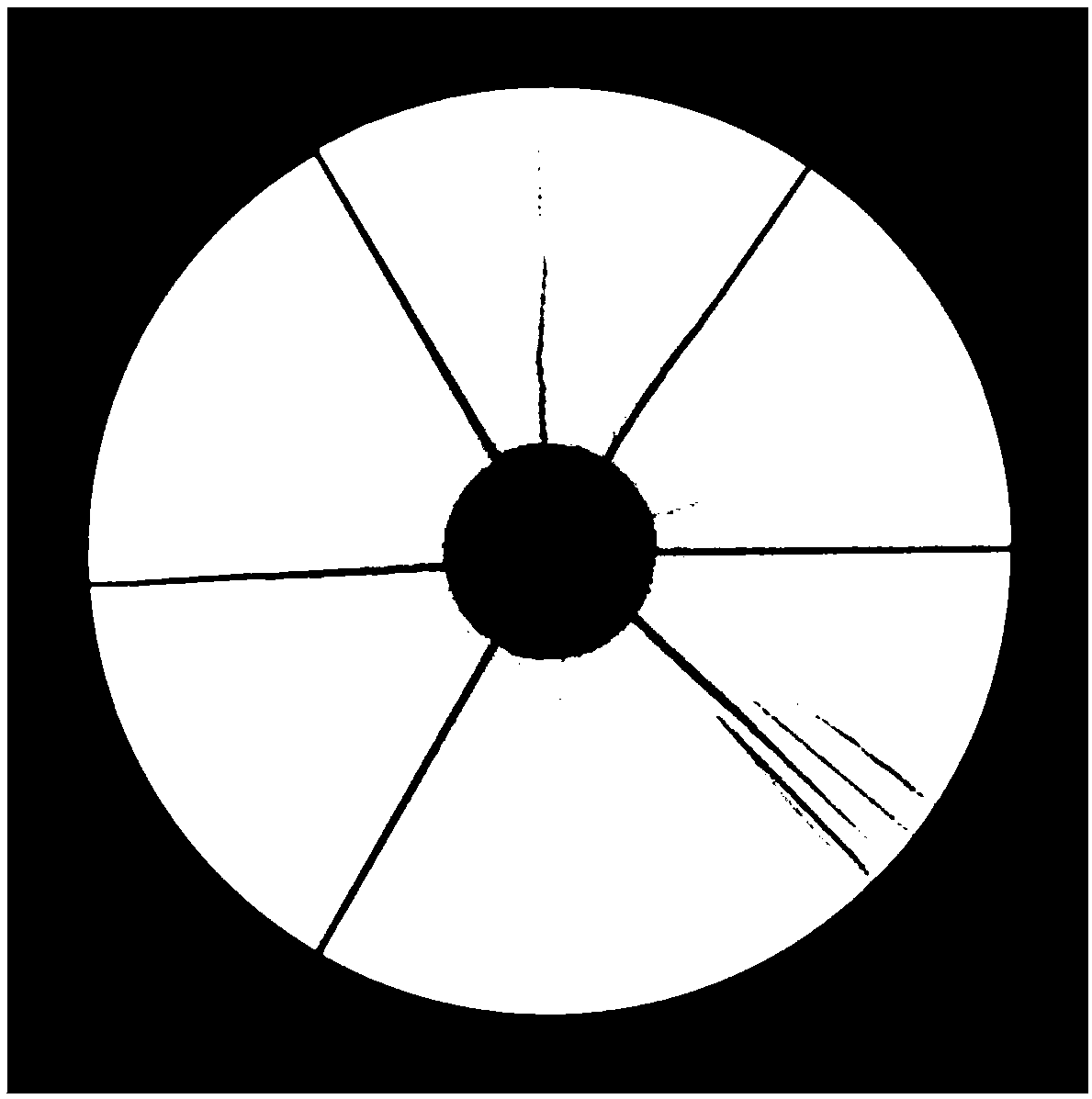

[0095] A crack extraction method based on iterative phase consistency, the method for CT images of cylindrical workpieces such as figure 1 , figure 2 Cracks are automatically extracted as shown.

[0096] Proceed as follows:

[0097] S0 combines the bottom hat transformation and denoising algorithm to preprocess the CT image to reduce the influence of background and noise on the image;

[0098] S1 performs polar coordinate transformation on the preprocessed image to obtain the image PolarImg;

[0099] S2 iteratively calculates the phase consistency of the image PolarImg in the polar coordinate system, and enhances the image;

[0100] S3 performs polar coordinate inverse transformation on the enhanced image;

[0101] S4 selects an appropriate threshold for the enhanced image, and then extracts the cracks in the image by threshold segmentation such as Figure 9 , Figure 10 shown.

[0102] The more specific steps of S2 are as follows:

[0103] Use PolarImg to represent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com