A magnetorheological fluid transmission device of high-temperature gear variable multi-face

A magneto-rheological fluid and multi-working surface technology, which is applied in fluid transmission devices, transmission devices, belts/chains/gears, etc., can solve problems such as increasing contact area, reducing transmission torque, and poor torque transmission stability , to achieve the effect of good torque stability, guaranteed torque size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

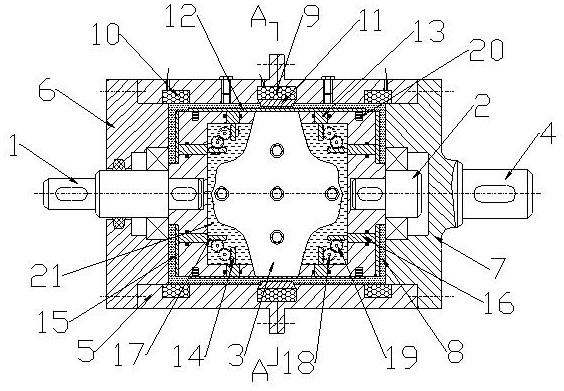

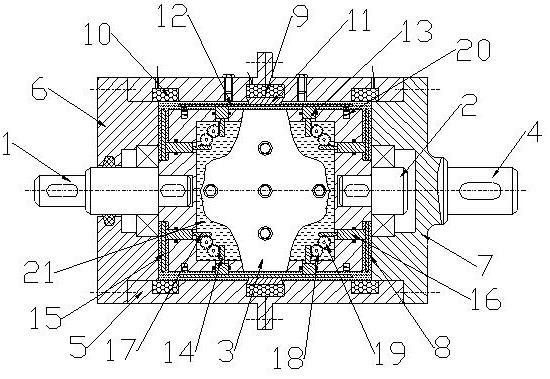

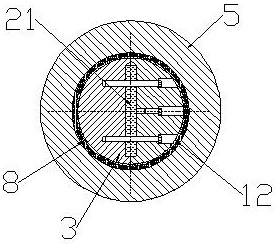

[0022] Example: see figure 1 , figure 2 as well as image 3 , a magneto-rheological fluid transmission device of high-temperature gear variable multi-face, including a left driving shaft 1, a right driving shaft 2, a driving inner cylinder 3, a driven shaft 4, a driven outer cylinder 5, and a left end cover 6 and Right end cap 7. Wherein, the right end cover 7 is formed by expanding the left end of the driven shaft 4; the left end cover 6 and the right end cover 7 are fixedly connected with the left and right ends of the driven outer cylinder 5 respectively. The two ends of the active inner cylinder 3 are closed structures; the right end of the left drive shaft 1 passes through the left end cover 6 and is fixedly connected with the left end of the active inner cylinder 3, and is connected with the left end cover 6 through a bearing, and the right drive shaft 2 The left end of the left end is fixedly connected with the right end of the driving inner cylinder 3, and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com