High wind pressure resistant plastic steel window structure

A wind pressure, plastic-steel technology, used in windows/doors, building components, building structures, etc., can solve problems such as reduced sealing performance, overall damage to windows, safety accidents, etc., achieve strong wind pressure resistance, and improve structural strength. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0018] In many areas, due to excessive wind pressure, there are many potential safety hazards in the application of plastic-steel windows, especially for windows with large compartments. The structural strength of the existing plastic-steel window structure is difficult to support the entire window well. , bringing quality and safety issues.

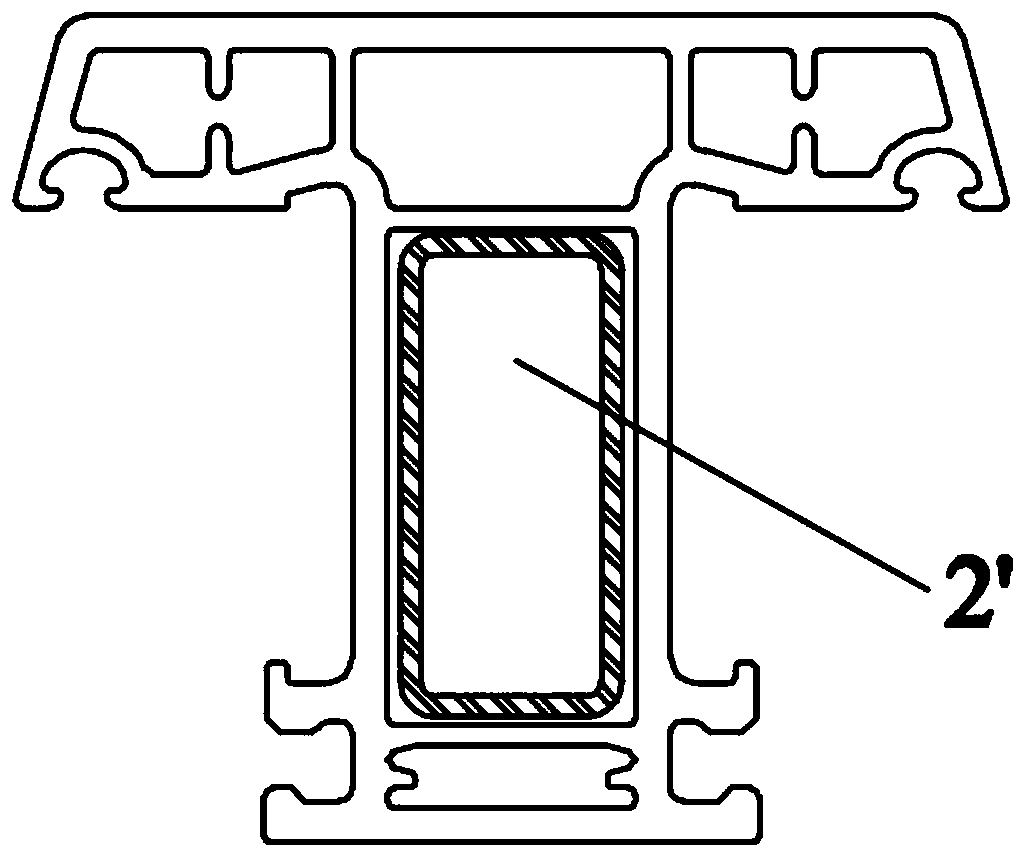

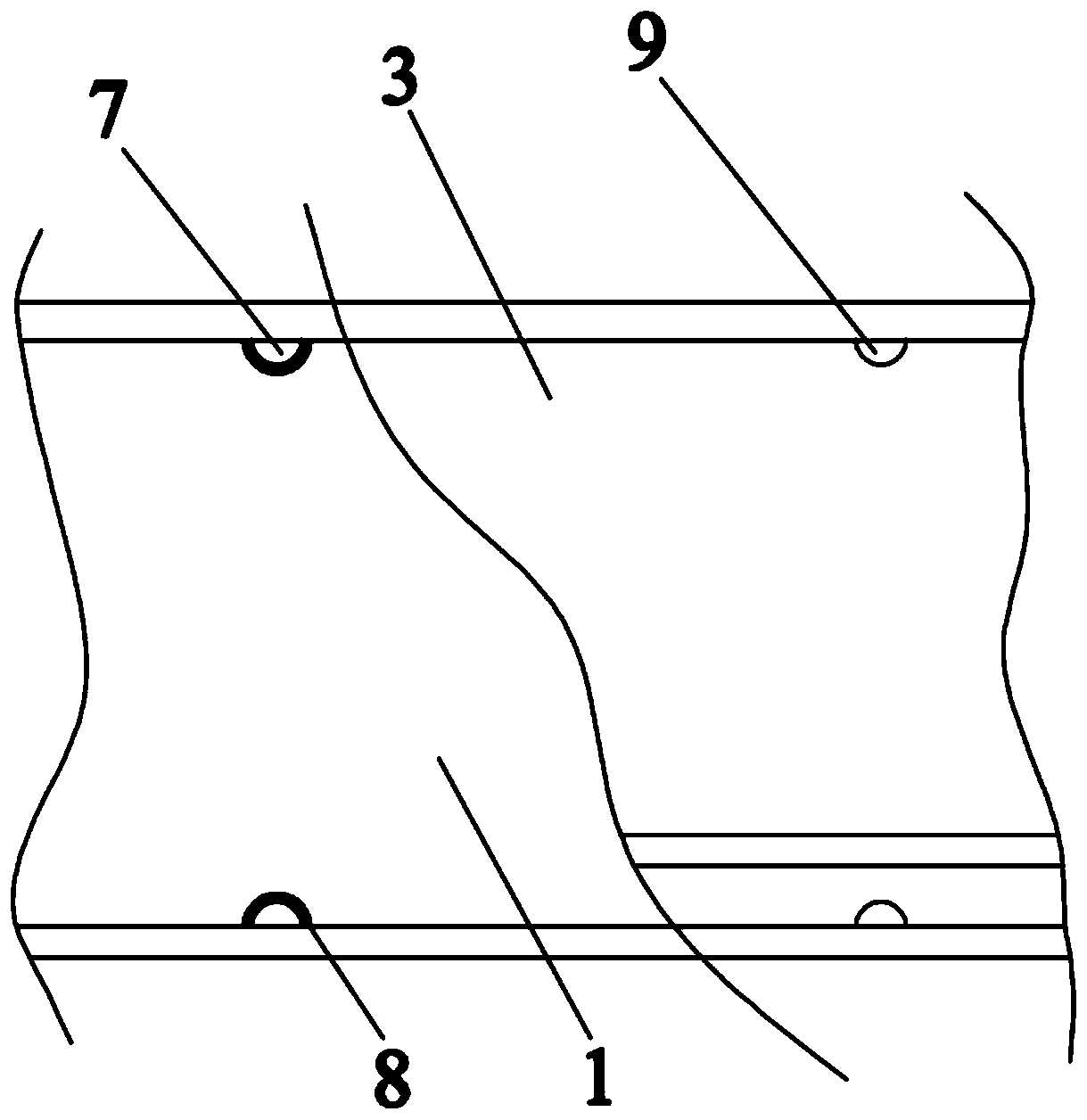

[0019] The high-wind-resistant plastic-steel window structure of the present invention enhances the overall wind-pressure resistance of the plastic-steel window by improving the structure of the stile. In the preferred embodiment of the present invention, please refer to figure 2 As shown, the high wind pressure resistant plastic steel window structure includes a frame and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com