Large-area blasting compaction treatment method of runway foundation

A treatment method and a large-area technology, which can be applied in basic structure engineering, soil protection, construction, etc., can solve problems such as reinforcement depth limitation, difficulty in meeting construction design requirements, and long construction period, and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

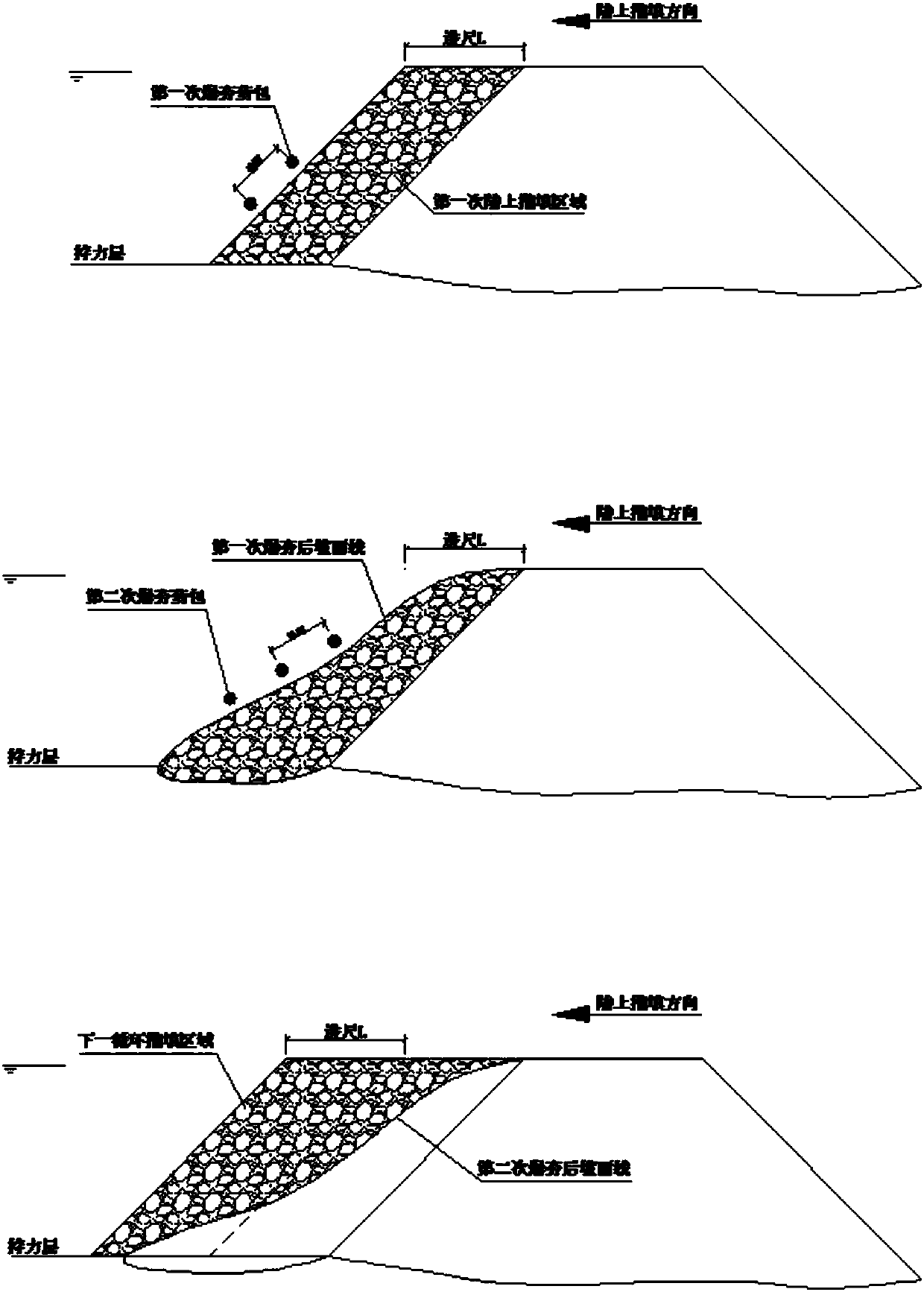

[0105] The construction technology is: push fill on land + explosive ramming on the underwater slope + dynamic ramming on land;

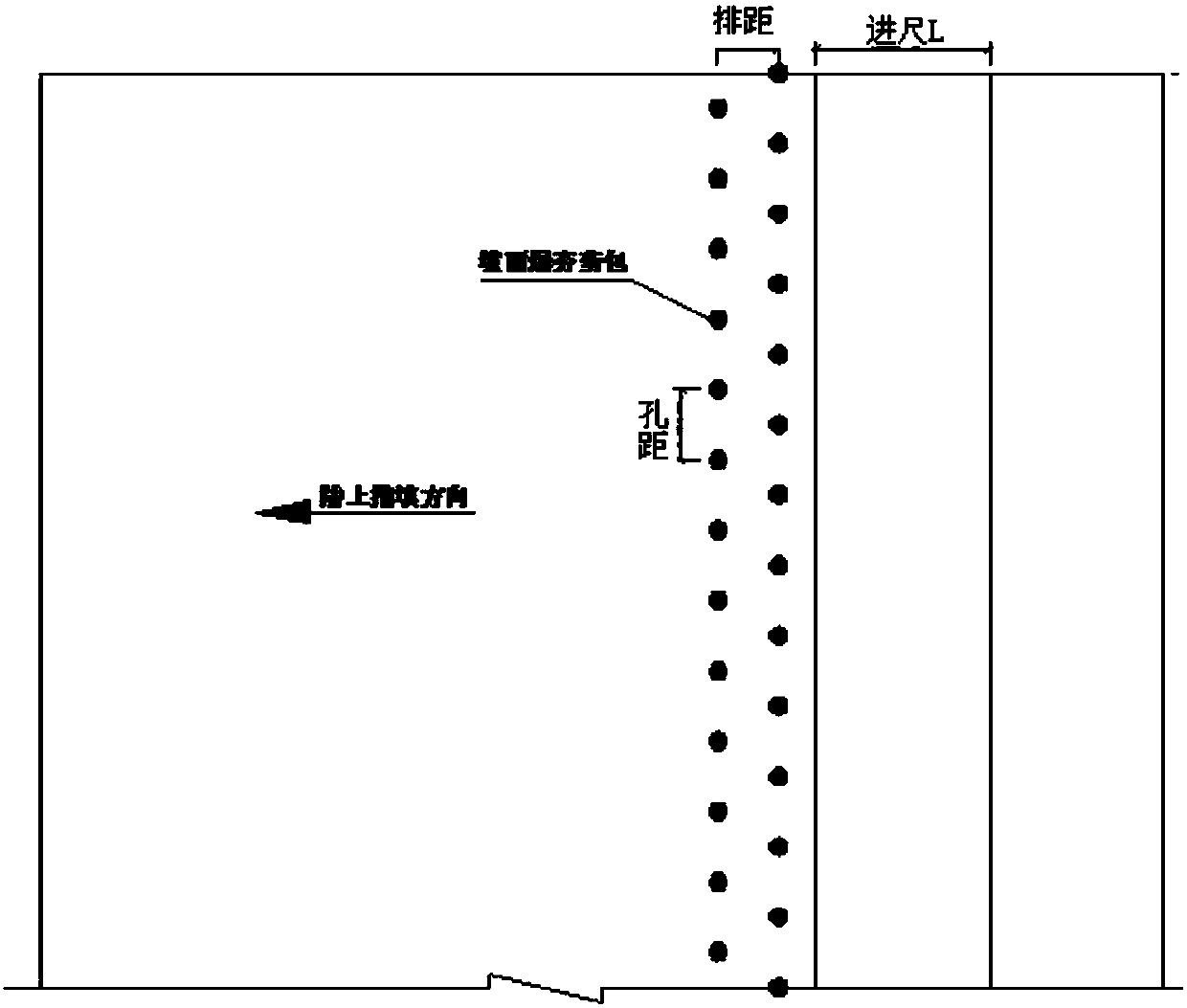

[0106] The construction plans to adopt the all-on-land push-fill construction and the underwater explosive ramming process on the slope surface, advancing along the full width of the short side of the test area, with a footage of 8 meters per shot.

[0107] (1) Explosive compaction construction technology

[0108] The first land-filling advance (width 120 meters, footage 8 meters, elevation +4 meters) → the first single row of explosive ramming on the slope surface to form a gentle slope platform → the second explosive ramming on the gentle slope surface → inspection of ramming settlement → the second The land throwing and filling of the second footage is advanced by 8 meters → the first explosive ramming on the slope of the second footage (cycle according to the above process until it is completely completed). The schematic diagram of the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com