A fully automatic anchoring mechanism suitable for upper rack pulley boxes

A fully automatic, pulley box technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve problems such as easy jamming, wear and scratches on hole walls, and automatic anchor release, etc., to achieve a safety factor High and low structural wear, stable and reliable anchoring and anchoring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

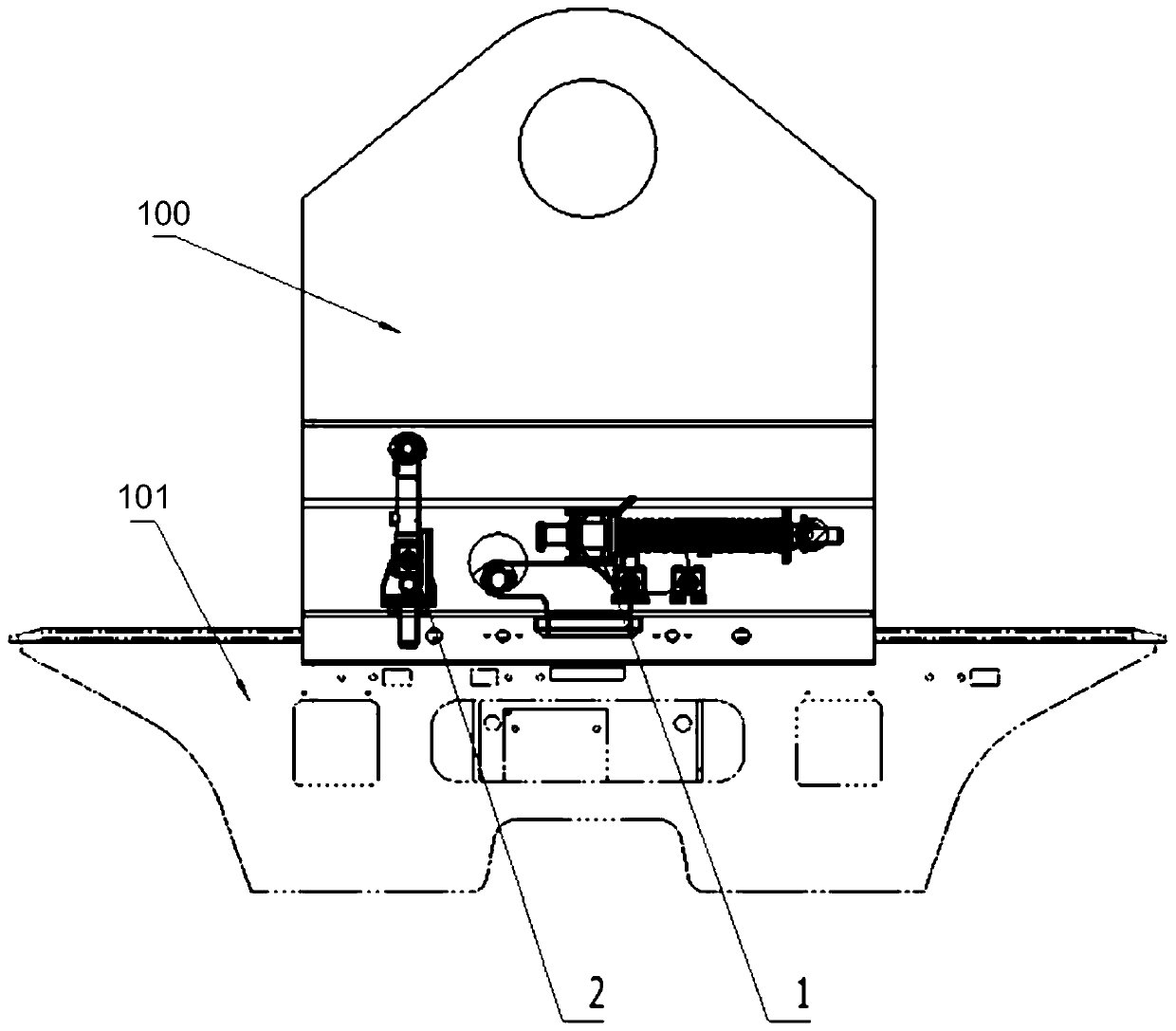

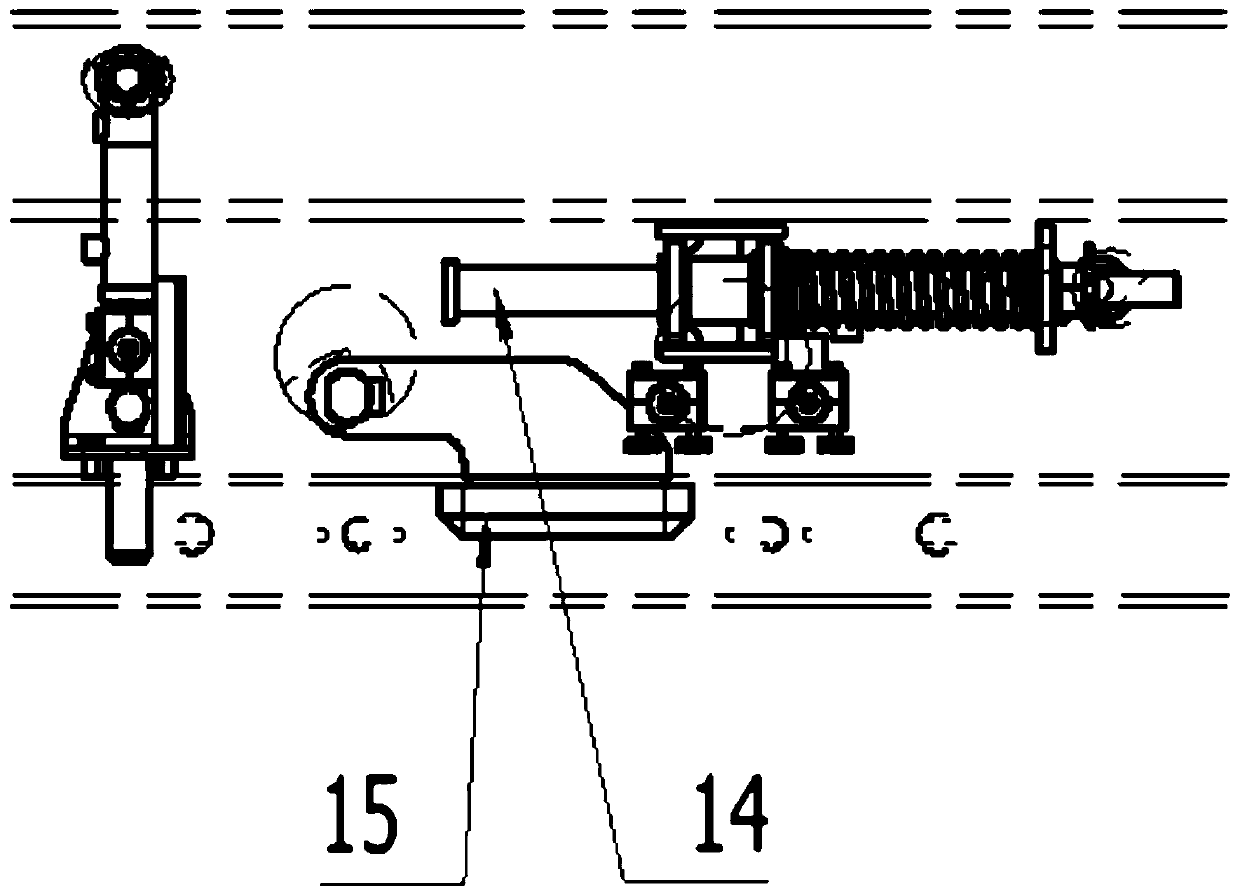

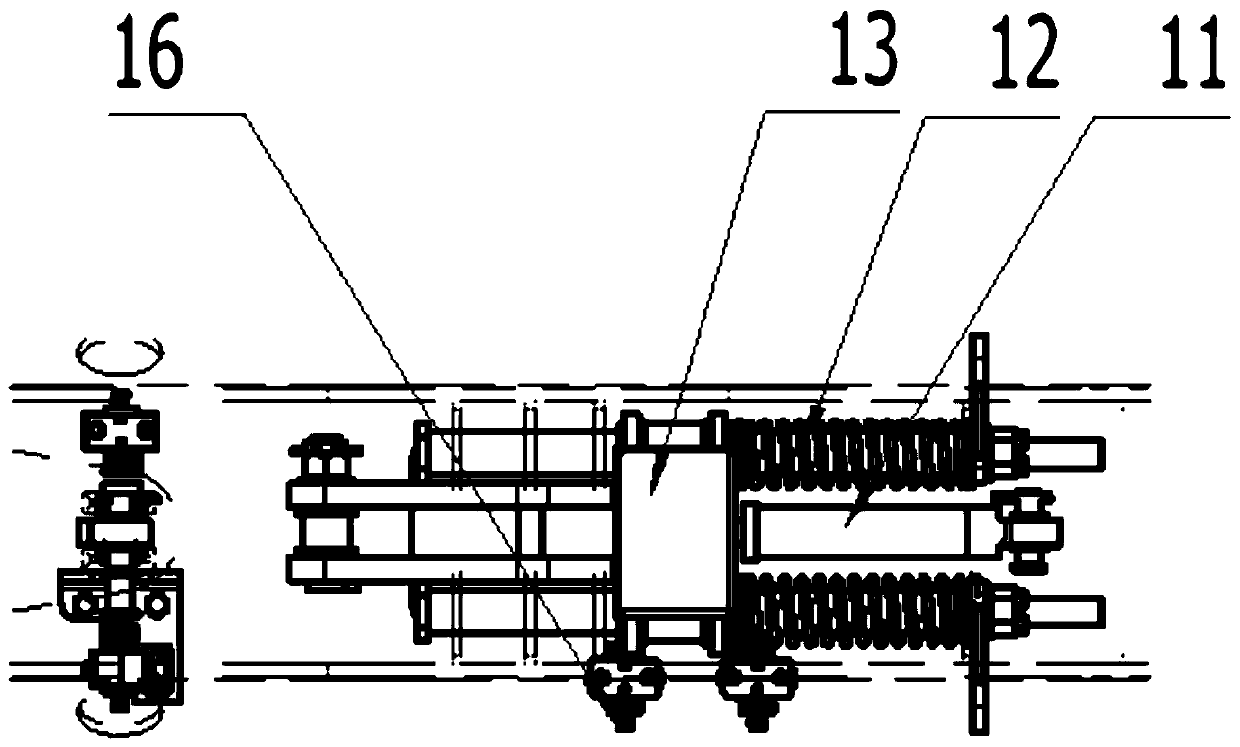

[0028] Please combine Figure 1 to Figure 9 As shown, a fully automatic anchoring mechanism suitable for upper-shelf pulley boxes provided by the present invention includes a pulley box 100 and a transition frame 101 connected to the pulley box 100. The above is a part of the prior art, and here I won't go into details. Different from the prior art, it also includes: a first anchoring mechanism 1 and a second anchoring mechanism 2 arranged on the pulley box 100 .

[0029] Preferably, the first anchor mechanism 1 includes: a first drive cylinder 11, a compression spring 12, a first anchor block 13, a guide rail 14 and a second anchor block 15, and the first drive cylinder 11 is installed on the pulley box On the body 100, the driving force is provided for the anchoring and unanchoring of the first anchoring mechanism 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com