Collection device of automatic packaging equipment

A collection device and automatic packaging technology, applied in packaging and other directions, can solve the problems of high difficulty, difficult to adjust, and uneven stacking, and achieve the effect of simple packaging process, time saving and packaging space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, experimental methods, etc. for implementing the present invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content.

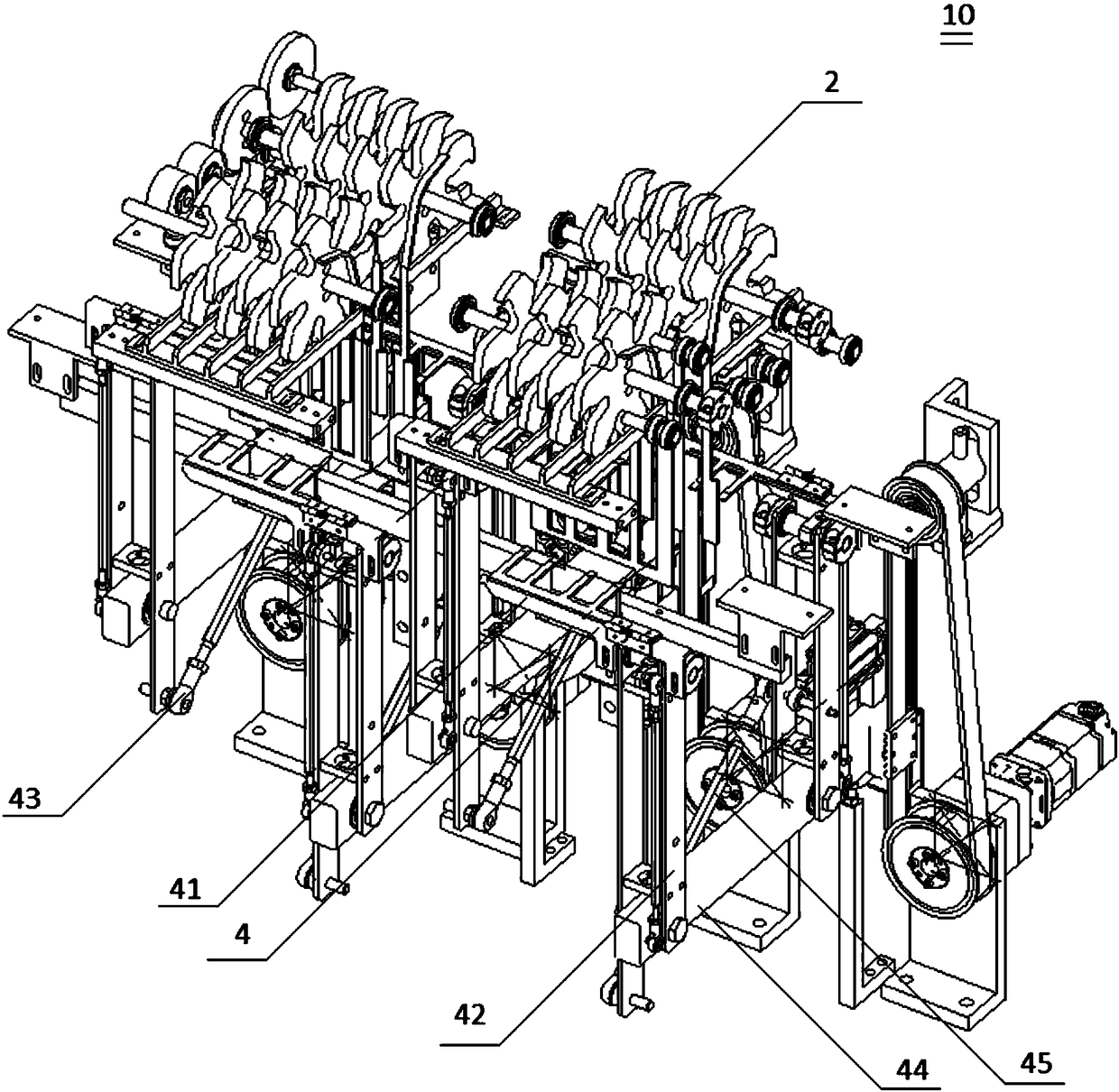

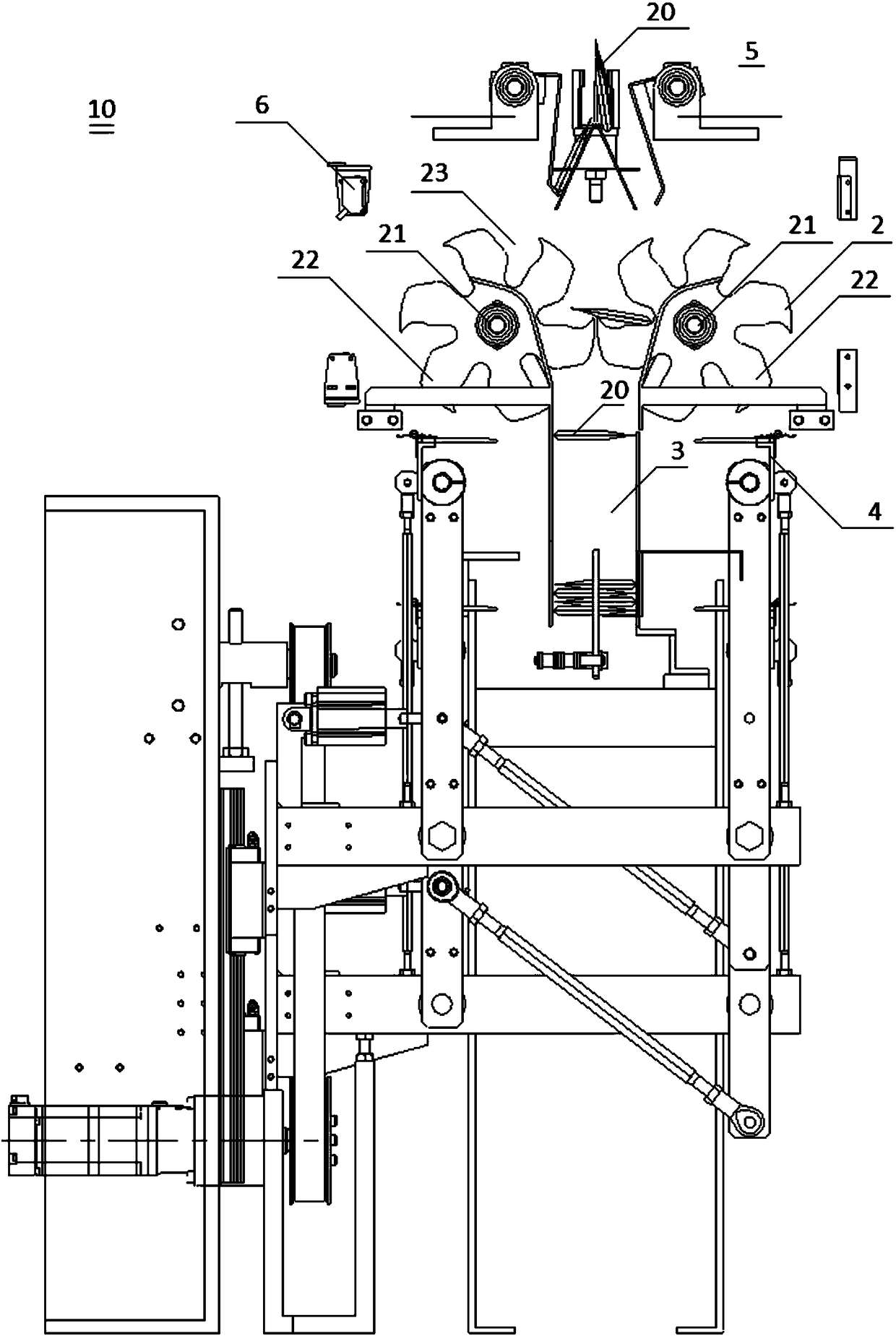

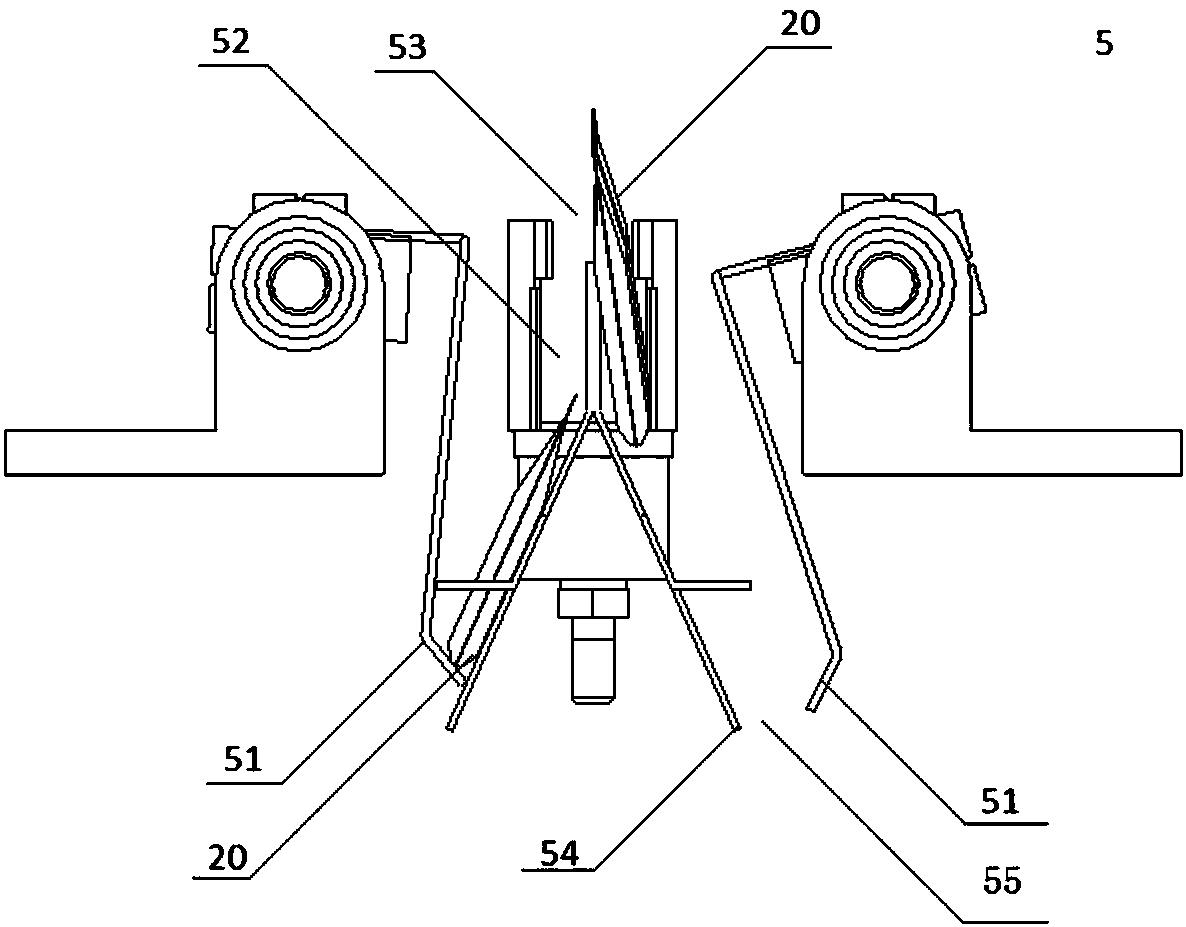

[0032] In the embodiment of the present invention, the corresponding labels of the various devices and parts of the automatic packaging equipment are as follows:

[0033] 10--collecting device; 20--packaging bag; 2--separation mechanism; 3-stacking space; 4--lifting mechanism; 5--separation mechanism; 6--counting sensor; 21--rotation shaft; Blade structure; 23--jaw; 41--stacking table; 42--vertical support rod; 43--lift shaft; 44-horizontal support rod; 45--push-pull shaft; -separation space; 53-inlet of packaging bag; 54-herringbone separation piece; 55-exit of packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com