Automatic gluing assembly line and gluing assembly method for vehicle lights

An assembly method and a technology of car lights, which are applied in the field of automobile manufacturing, can solve problems such as unfavorable curing beats, easy peeling of adhesive strips, and low production efficiency, so as to improve bonding reliability and durability, finely remove static electricity, and reduce land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

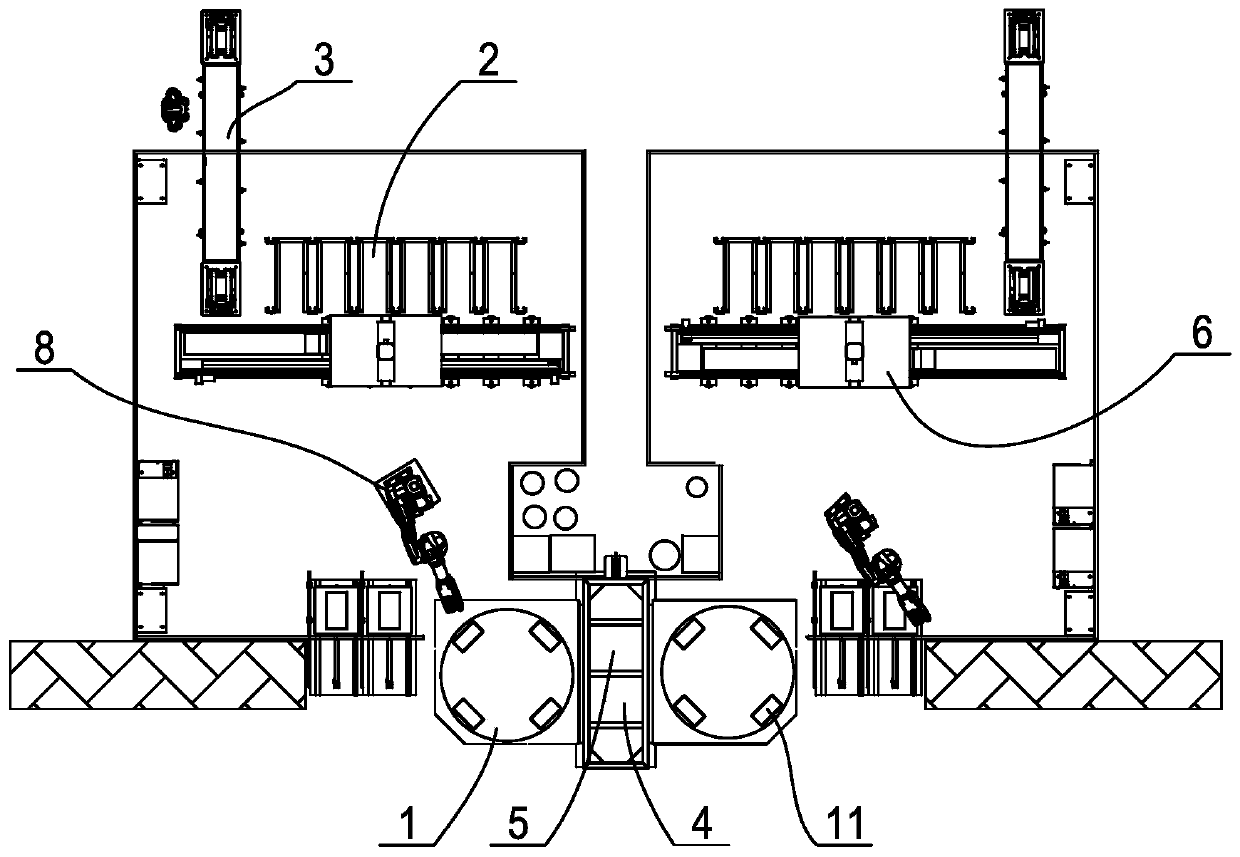

[0039] Embodiment 1: as figure 1 , figure 2 As shown, an automatic gluing assembly line for headlights, including:

[0040] A rotary table 1, four positioning devices 11 for placing lamp holder assemblies are arranged on the rotary table, and No. 1 station, No. 2 station, No. 3 station, and No. No. station. When the rotary table rotates step by step at a rotation angle of 90 degrees, the positioning device rotates to the No. 1, No. 2, No. 3, and No. 4 stations in turn, and then turns back to No. 1 station. Of course, the positioning device should be evenly divided along the circumferential direction on the rotary table, and the positioning groove should be provided on the positioning device to match the shape of the lamp holder in the lamp holder assembly, so that the lamp holder assembly can be positioned reliably and accurately. on the positioning device;

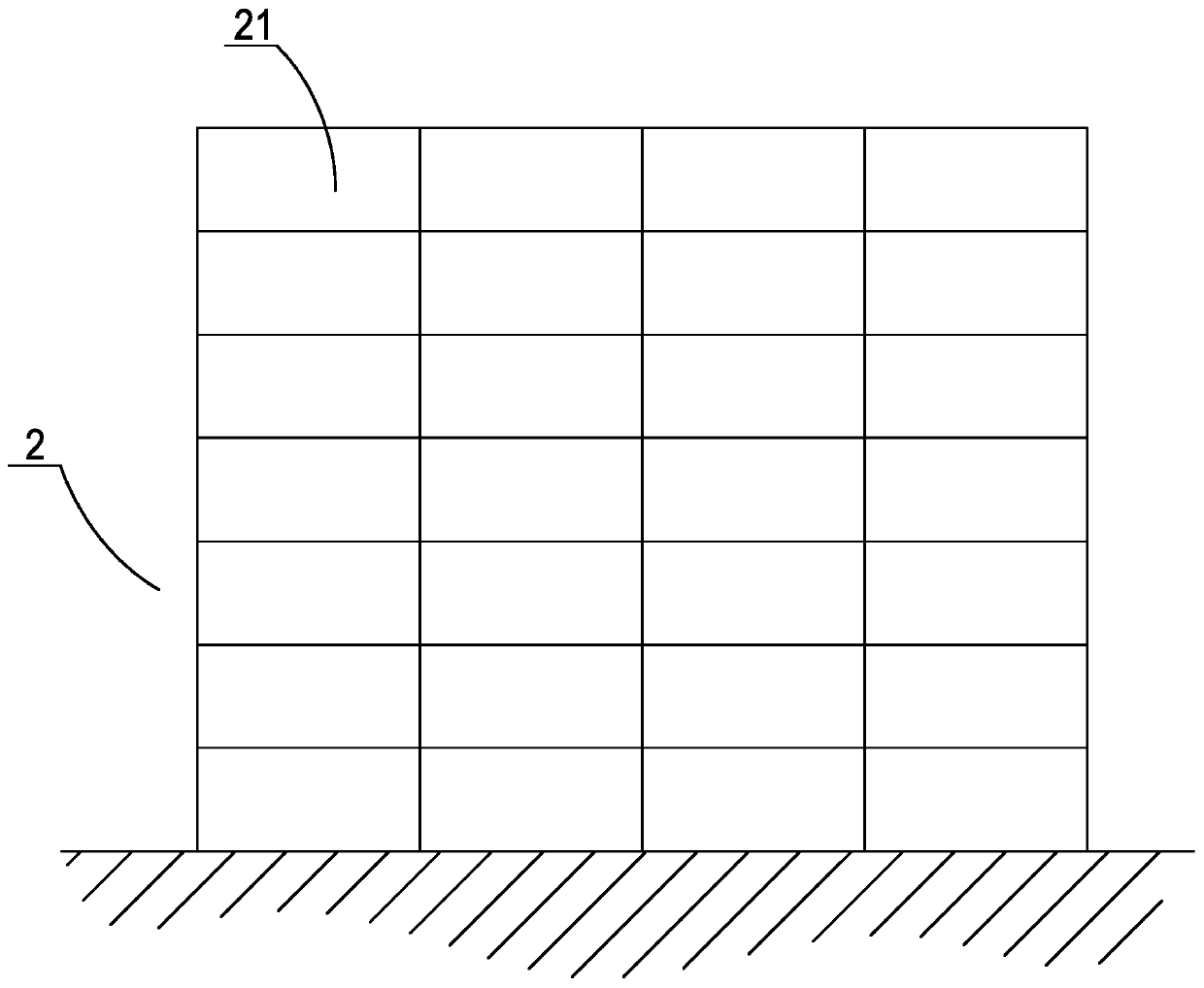

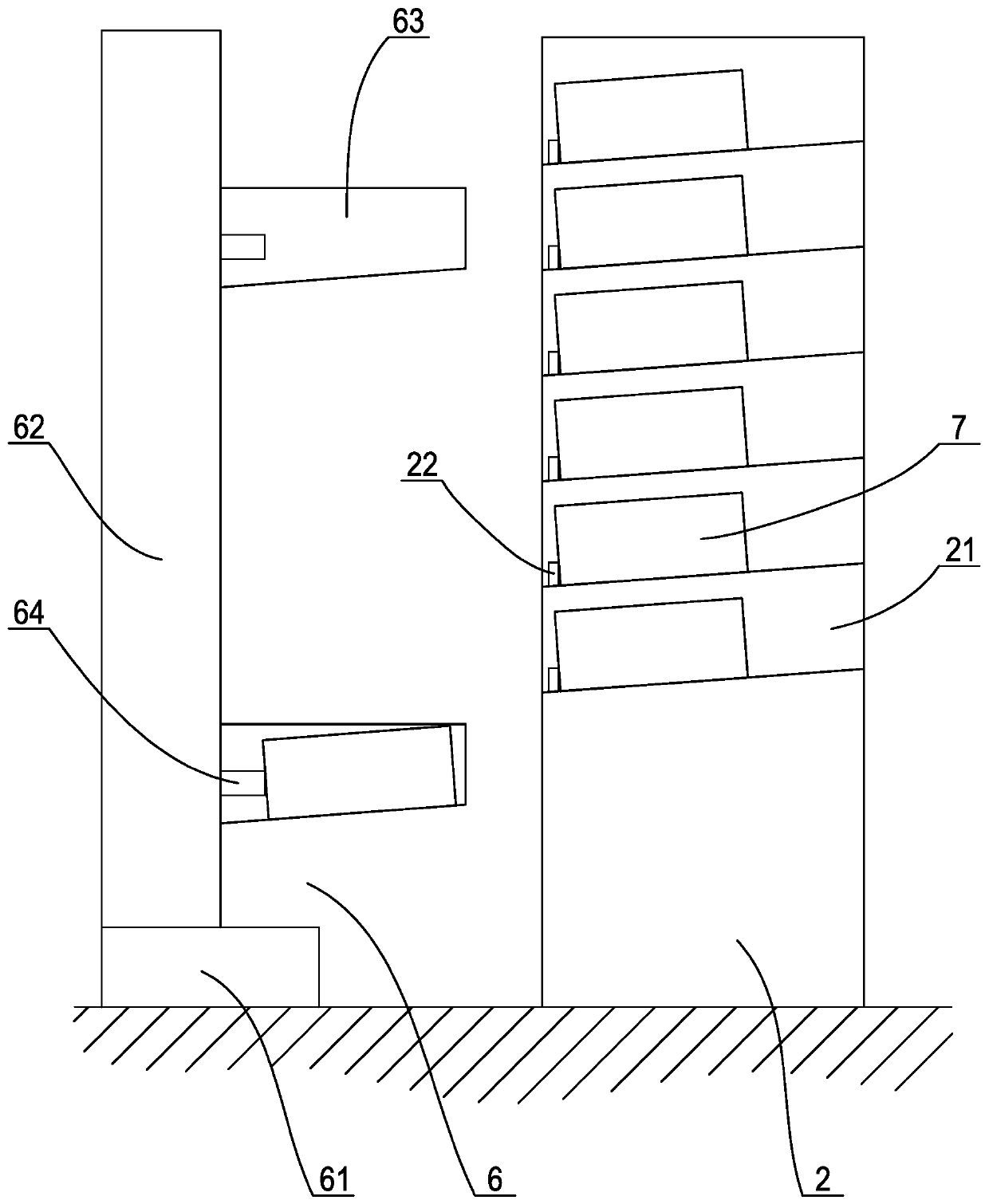

[0041] A three-dimensional curing tower 2, on which a plurality of curing locations in a rectangular array need to...

Embodiment 2

[0054] Embodiment 2: A method for automatic gluing assembly of vehicle lights, which can be completed by using the automatic gluing assembly line for vehicle lights as described in Example 1, including the following steps:

[0055] a. Start to set up four positioning devices and make a step-by-step rotary table. When the rotary table rotates step-by-step at a rotation angle of 90 degrees, the four positioning devices on the rotary table are on the first and second positions in sequence. No. 1, No. 3, and No. 4 stations rotate among them, among which No. 1 station is used to place the equal seat assembly, No. 2 station is used for surface treatment of the lamp holder of the equal seat assembly, and No. 3 station is used for Automatic gluing is carried out, and the No. 4 station is used for snap-fit assembly of lamp covers and other seat components. That is to say, when the rotary table rotates 360 degrees, the positioning device can rotate from the No. 1 station to the No. 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com