Self-propelled pneumatic pipeline cleaning machine and cleaning method

A technology for pneumatic pipes and cleaning machines, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of heavy equipment, inconvenient operation, poor cleaning effect, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

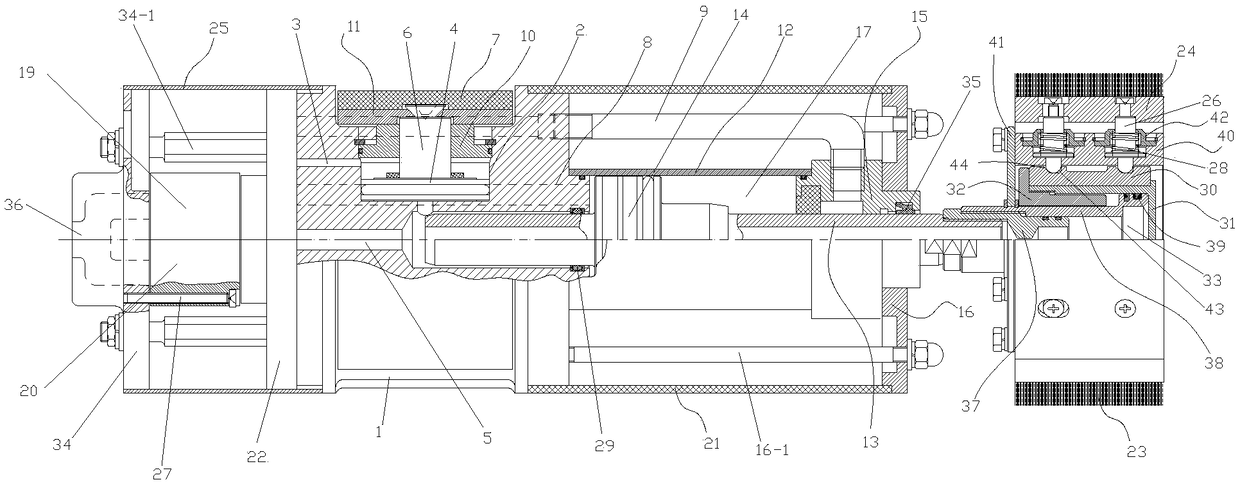

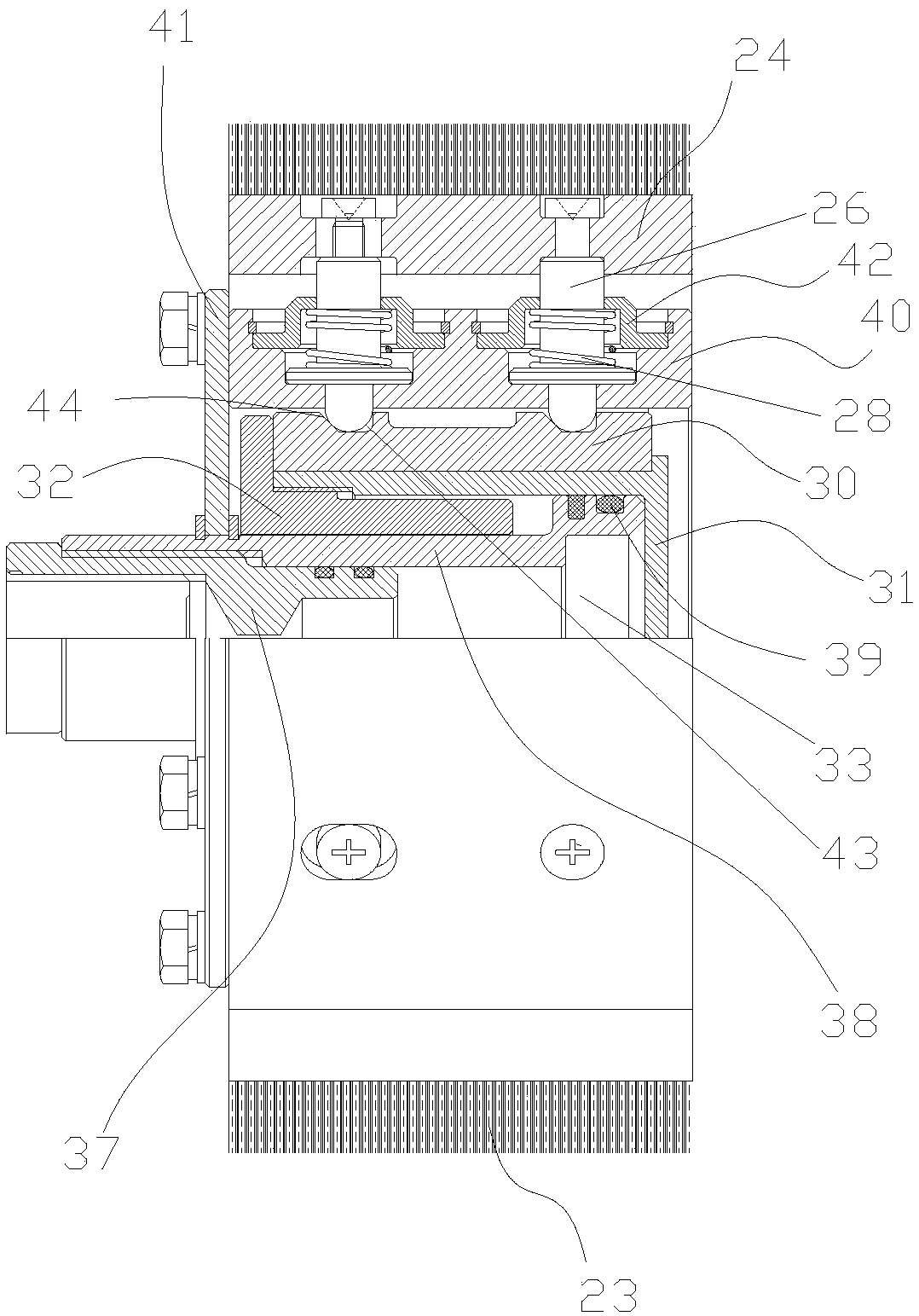

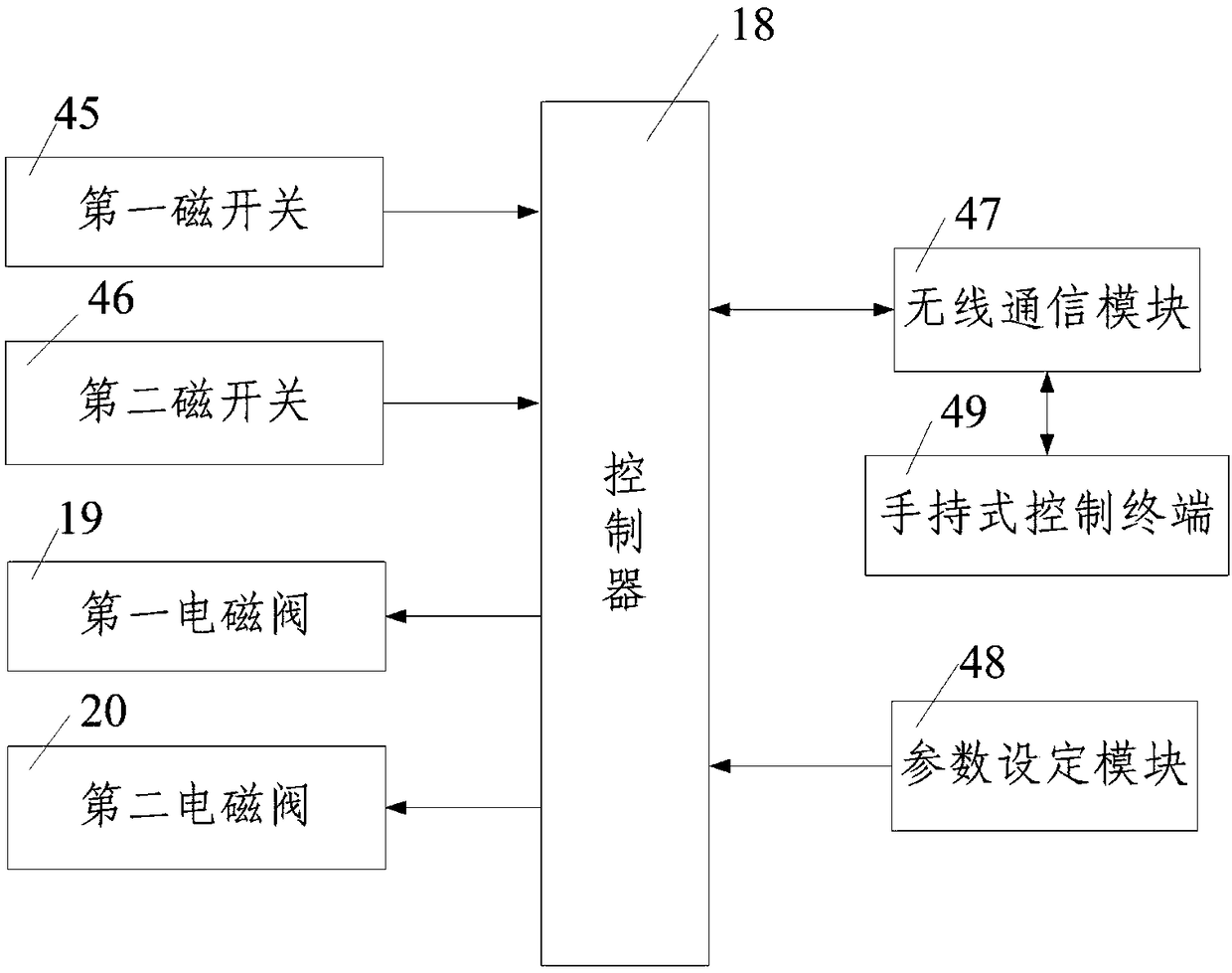

[0067] Such as figure 1 , figure 2 and image 3 As shown, the self-propelled pneumatic pipeline cleaning machine of the present invention includes a pipeline cleaning mechanism that is arranged inside the pipeline to be cleaned and cleans the inner wall of the pipeline to be cleaned, and a monitoring device that monitors the pipeline cleaning mechanism. The pipeline cleaning mechanism includes A guide plate 22 for compressed gas to pass through, a braking mechanism fixedly connected to the guide plate 22 on one side, a cleaning head mechanism installed on the other side of the braking mechanism, and driving the cleaning head mechanism along the inner wall of the pipeline to be cleaned A reciprocating drive mechanism for reciprocating movement, the brake mechanism includes a brake housing 1 fixedly connected to the guide plate 22 on one side, a plurality of brake housings 1 uniformly arranged along the circumferential direction and can be in close contact with the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com