Online olefin and oxygen mixing device

A mixing equipment and olefin technology, applied in mixers, fluid mixers, transportation and packaging, etc., can solve the problems of unsatisfactory mixing effect of olefins and oxygen, and achieve reduced flow cross-section, increased pressure drop, and uniform speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

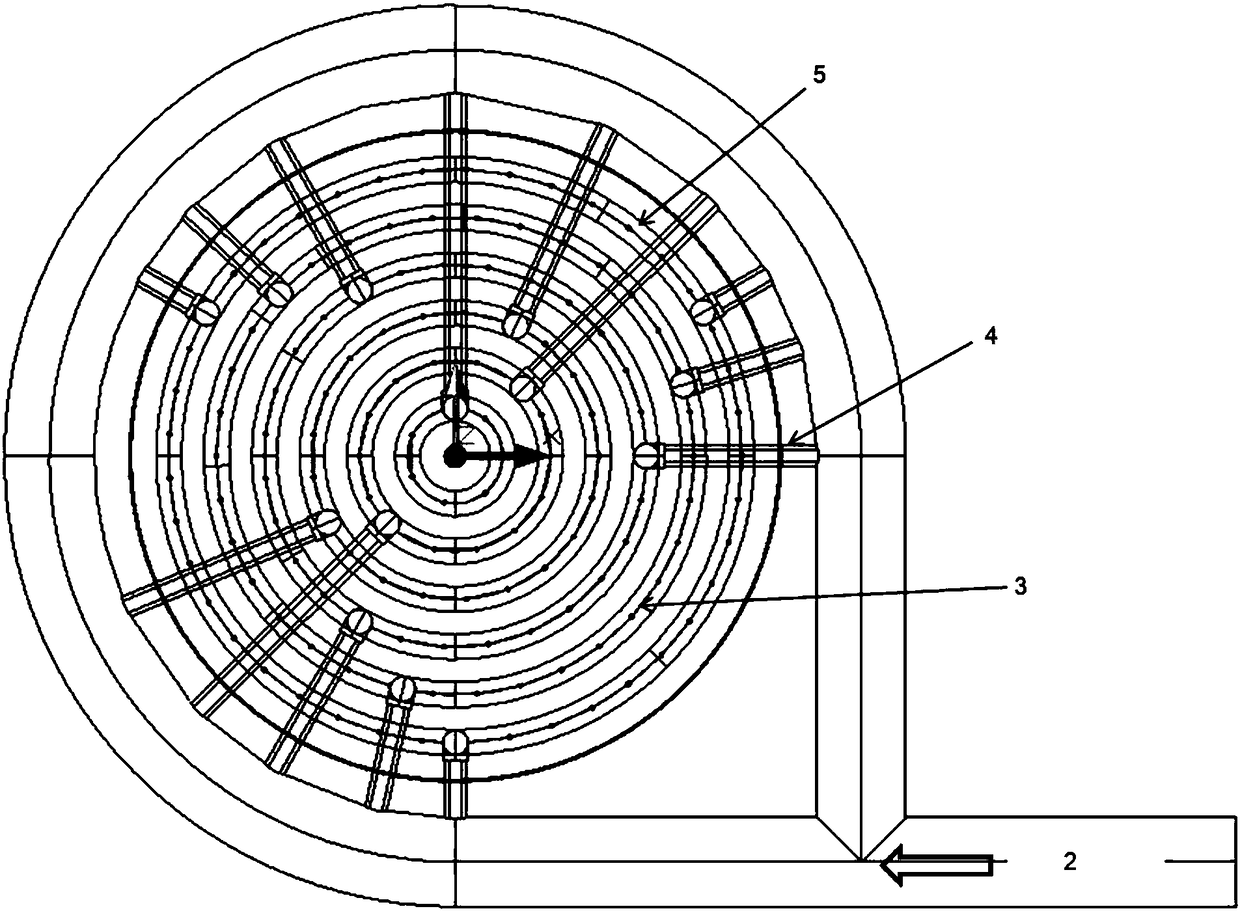

[0024] An in-line mixing device for olefins and oxygen, such as figure 1 , 2 As shown, it includes the olefin main pipeline, oxygen pipeline, and mixing chamber. The end of the olefin main pipeline is connected to the mixing chamber. Several annular distribution pipes are arranged in the mixing chamber. The plane of the annular distribution pipes is perpendicular to the flow direction of olefins. The opening direction of the nozzle is consistent with the flow direction of olefins. The oxygen pipeline is divided into several branch pipes outside the main pipeline and then enters the circulation gas main pipe to connect with the circular distribution pipe. All the annular distribution pipes are arranged on a plane so that The olefins are rapidly mixed with the oxygen sprayed from the nozzle of the circular distribution pipe in the mixing zone.

[0025] The structural parameters of the online mixing equipment mixer are as follows:

[0026] The inner diameter of the olefin main ...

Embodiment 2

[0042] According to the conditions and steps described in embodiment 1, the structural parameters of the online mixing equipment mixer are as follows:

[0043] The structural parameters of the online mixing equipment mixer are as follows:

[0044] The inner diameter of the olefin main pipeline: DN1100, the diameter of the ring distribution pipe: DN65, the number of ring distribution pipes is 5, the average flow velocity in the distribution pipe is 6m / s, the ring distribution pipe 1 is connected with a branch pipe, and the ring distribution pipe is 2 / 3 It is connected with 2 branch pipes, and the annular distribution pipe 4 / 5 is connected with 3 branch pipes. The average flow velocity of each branch pipe is 5m / s, and the distance between two adjacent distribution rings is 95mm; the pipe diameter of the branch pipe : DN65, nozzle diameter: 3mm, nozzle speed is 70m / s, nozzle spacing is 4.3 times the nozzle diameter, and the number of nozzles is 103; the diameter of the circular d...

Embodiment 3

[0060] According to the conditions and steps described in Example 1, the structural parameters of the mixer of the online mixing device are as follows:

[0061] On-line mixing equipment mixer structure parameters are as follows:

[0062] The inner diameter of the olefin main pipe: DN1100, the diameter of the annular distribution pipe: DN25, the number of annular distribution pipes is 10, the average flow velocity in the distribution pipe is 16m / s, and 1 / 2 / 3 of the annular distribution pipe is connected to a branch pipe. Piping 4 / 5 is connected with 2 branch pipes, annular distribution pipe 6 / 7 is connected with 3 branch pipes, annular distribution pipe 8 / 9 is connected with 4 branch pipes, annular distribution pipe 10 is connected with 5 branch pipes, each The average flow velocity of the branch pipe is 12m / s, and the distance between two adjacent distribution rings is 65mm; the pipe diameter of the branch pipe: DN25, the nozzle diameter: 4mm, the nozzle speed is 70m / s, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com