Negative electrode and secondary battery including same negative electrode

A technology for negative electrodes and current collectors, applied in the field of negative electrodes and secondary batteries containing them, can solve the problems of electrode thickness thickening, achieve the effects of minimizing thickness changes, improving mechanical stability, and improving distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

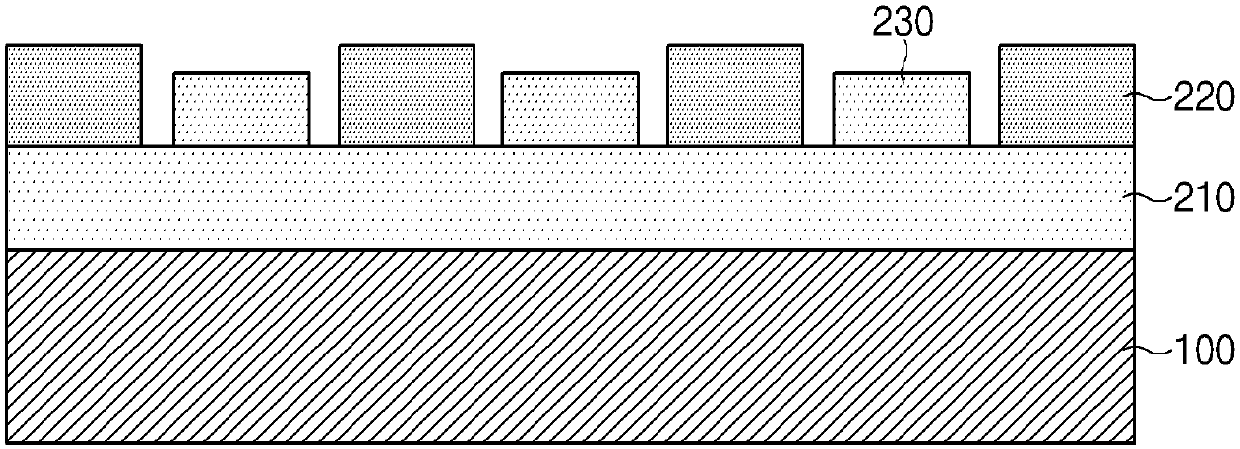

Image

Examples

specific example

[0057] In addition, the positive electrode binder improves the adhesion between the positive electrode active material particles, and the adhesion between the positive electrode active material and the positive electrode current collector. The following can be specific examples of the positive electrode binder: polyvinylidene fluoride (PVDF), PVDF-co-HFP, polyvinyl alcohol, polyacrylonitrile, CMC, starch, hydroxypropyl cellulose, regenerated cellulose, poly Vinylpyrrolidone, tetrafluoroethylene, polyethylene, polypropylene, EPDM, sulfonated EPDM, SBR, fluororubber and its various copolymers, and one or at least two of the above adhesives can be used combination.

[0058] The separator separates the negative electrode from the positive electrode and provides a path for lithium ions, and the separator can be used without particular limitation as long as it is a separator commonly used in a secondary battery, and in particular, for ions A separator that has low resistance to mov...

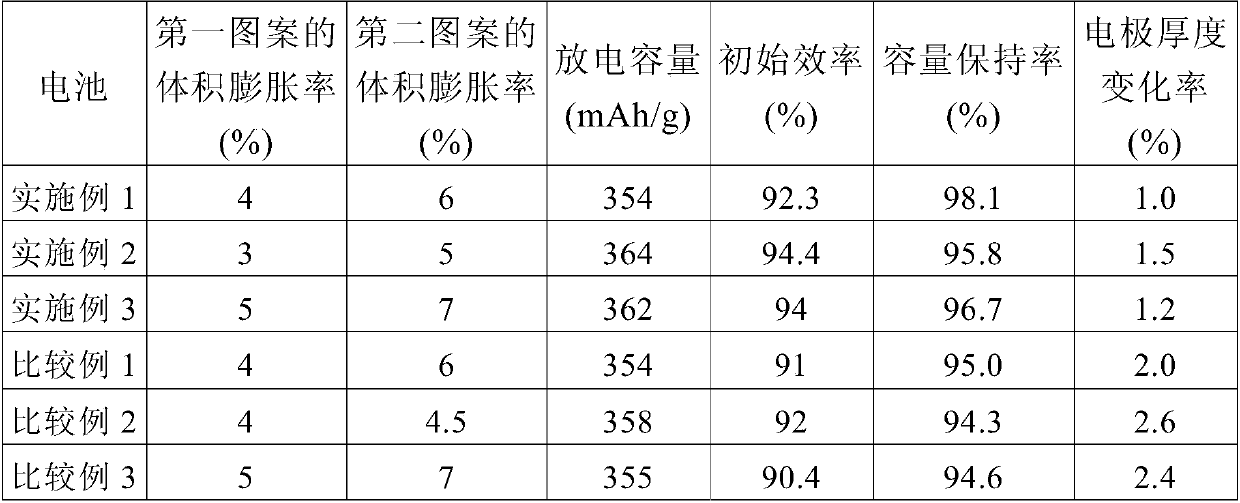

Embodiment 1

[0068] Embodiment 1: the manufacture of battery

[0069] (1) Manufacture of negative electrode

[0070] 1) Formation of the first active material layer

[0071] By taking the mean diameter (D 50 ) of 20.4 μm artificial graphite, carbon black as a conductive material, and CMC and SBR as a binder were mixed at a weight ratio of 95.8:1:1.7:1.5 to manufacture 5 g of a mixture. Negative electrode slurry was produced by adding 28.9 g of distilled water to the mixture. A copper current collector with a thickness of 20 μm was coated with the negative electrode slurry and dried. At this time, the temperature of the circulating air was 120°C. Thereafter, by performing a rolling process, a first active material layer having a thickness of 50 μm was formed.

[0072] 2) Formation of the second pattern

[0073] By taking as the average diameter (D of the second pattern active material particle 50 ) of 15 μm, carbon black as a conductive material, and CMC and SBR as a binder were mixe...

Embodiment 2

[0080] Embodiment 2: the manufacture of battery

[0081] (1) Manufacture of negative electrodes and batteries

[0082] Instead of using the mean diameter (D 50 ) is 16 μm of natural graphite as the first active material particle, using the average diameter (D 50 ) is artificial graphite of 20 μm as the first pattern active material particles, and use the average diameter (D 50 ) of 15.6 μm artificial graphite as the second pattern active material particles, a negative electrode and a battery were manufactured in the same manner as in Example 1. At this time, the thickness of the first active material layer was 50 μm. In addition, the first pattern had a thickness of 40 μm and a porosity of 28%. In addition, the second pattern had a thickness of 20 μm and a porosity of 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com