Parallel Ditch Clamp Lap

A technology of lap joints and wire clamps, which is applied in the direction of multi-core cable end parts, etc., and can solve problems such as low work efficiency and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

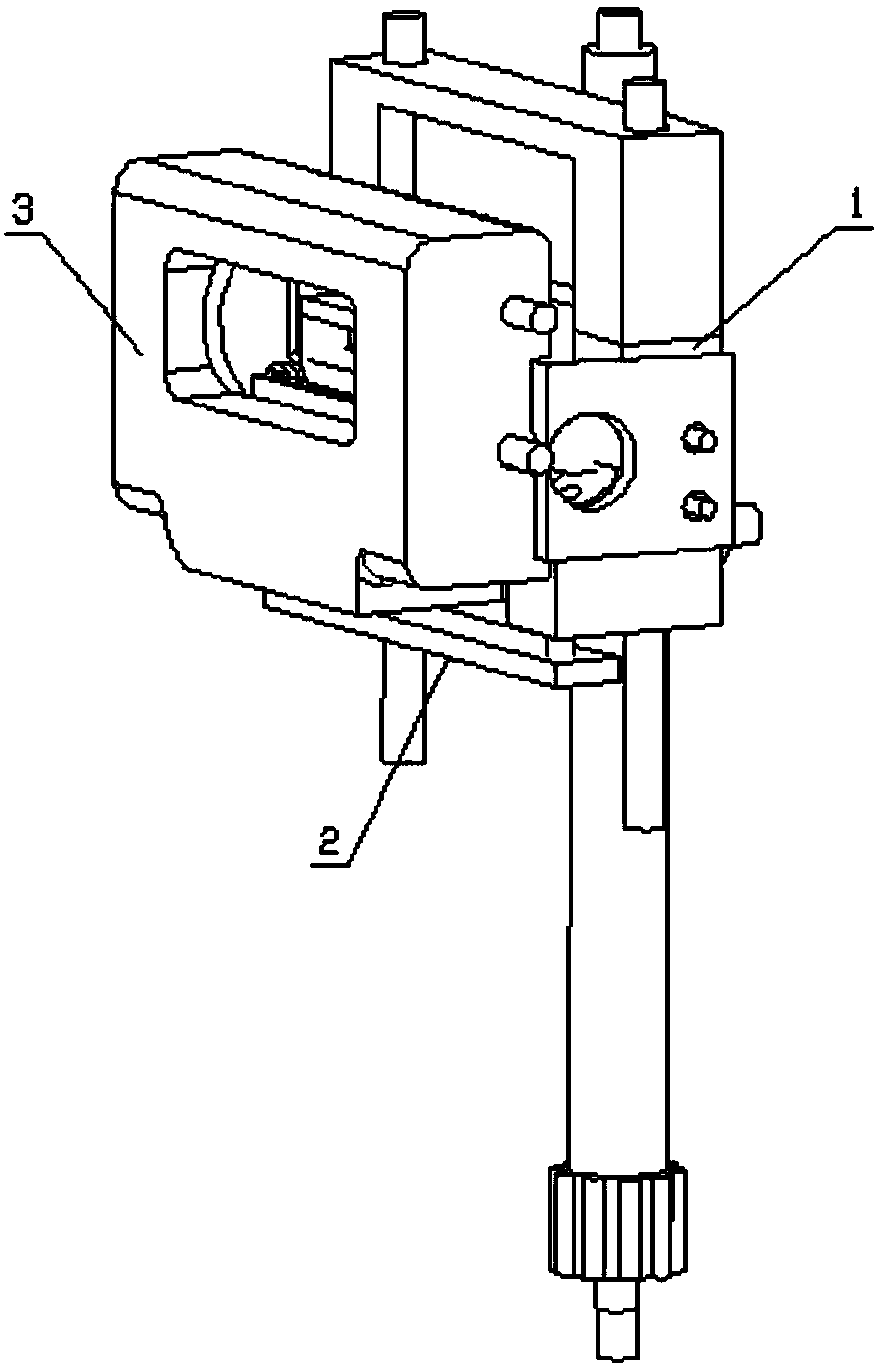

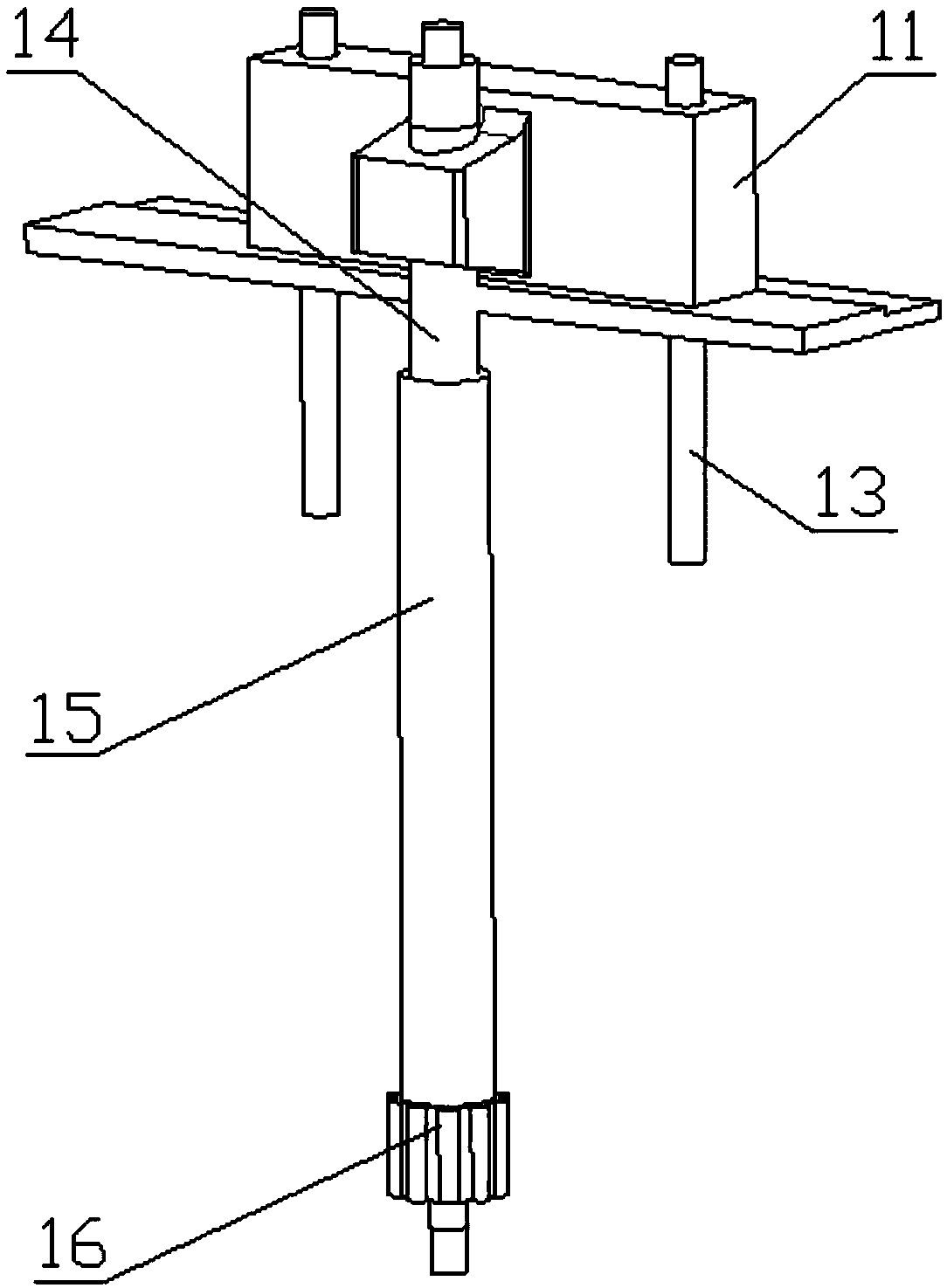

[0021] Such as Figure 1 to Figure 3 As shown, the parallel ditch wire clamp overlapper includes a wire clamp fixer 1, a lead wire locker 2 and a press cylinder fixer 3, and the wire clamp fixer 1 includes a first wire clamp fixing block 11, which is located on the first The second wire clamp fixed block 12 on the lower side of the wire clamp fixed block, the guide connecting rod 13 connecting the first wire clamp fixed block 11 and the second wire clamp fixed block 12, makes the first wire clamp fixed block 11 and the second wire clamp fixed block 12 The wire clip holder control structure for clamping or loosening the parallel trench wire clip, the second wire clip fixing block 12 is provided with a lead wire passing groove 121 for the lead wire to pass through transversely.

[0022] refer to figure 2 and image 3 As shown, the first wire clamp fixing block 11 is provided with a first U-shaped groove 111, the second wire clamp fixing block 12 is provided with a second U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com