A kind of automatic threading method and threading device for traveler of ring spinning frame

A threading method and traveler technology, which are used in spinning machines, piecing devices, textiles and papermaking, etc., can solve the problem of inability to rotate the traveler, and achieve the effect of shortening threading time, improving success rate and speeding up efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

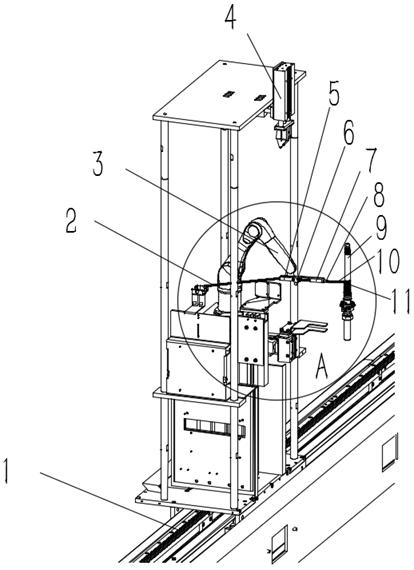

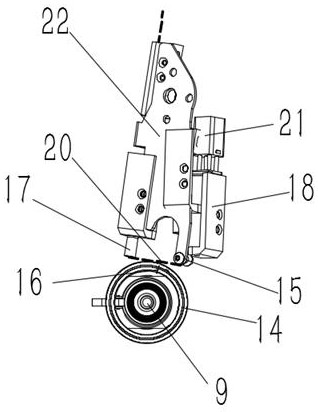

[0048] A ring spinning machine traveler automatic threading device, comprising a wire feeder 6 and a circulation generator 7, the wire feeder 6 comprises a fixing plate 22 fixed on the end 5 of the mechanical arm on the mechanical arm 3, and the mechanical arm 3 is fixed on the platform 2, the platform 2 moves along the guide rail 1, the left side of the fixing plate 22 is provided with a first venturi, a yarn fixing device and a second venturi, and the yarn fixing device is located at the first venturi and the second venturi. In the middle of the inner tube, the end of the second venturi tube is provided with a yarn nozzle 17, and the other side of the fixing plate is provided with a yarn fixing shaft 15. Both the yarn nozzle 17 and the yarn fixing shaft 15 are yarn clamping devices 8 , the two cooperate to form the threading part 20 of the yarn.

[0049] In use, the first venturi tube sucks the yarn 10, after passing through the yarn fixing device, it enters the second ventu...

specific Embodiment 2

[0051] An automatic threading method for a traveler of a ring spinning frame,

[0052] As soon as a yarn break is detected at one of the spinning stations of the ring spinning frame, the robot arm 3 receives a signal from the processing and control of the system, moves along the guide 1 and is centered in front of the spindle tube for the yarn break spinning station.

[0053] The first venturi tube sucks the yarn 10, after passing through the yarn fixing device, it enters the second venturi tube, and is ejected from the yarn nozzle, and the yarn end 11 contacts the yarn tube 9 and is wound around the yarn tube;

[0054] - Step a) Through the action of the robotic arm, under the combined action of the two types of yarn gripping devices in the yarn gripping device 8, namely the yarn fixing shaft 15 and the yarn nozzle 17, the yarn fixing shaft 15 and the yarn nozzle 17 work together. A threading portion 20 of the yarn is formed between the nozzles 17 .

[0055] - Step b) The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com