CRTS II slab-type ballastless track mortar bonding quality detection equipment and method

A slab ballastless track, bonding quality technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

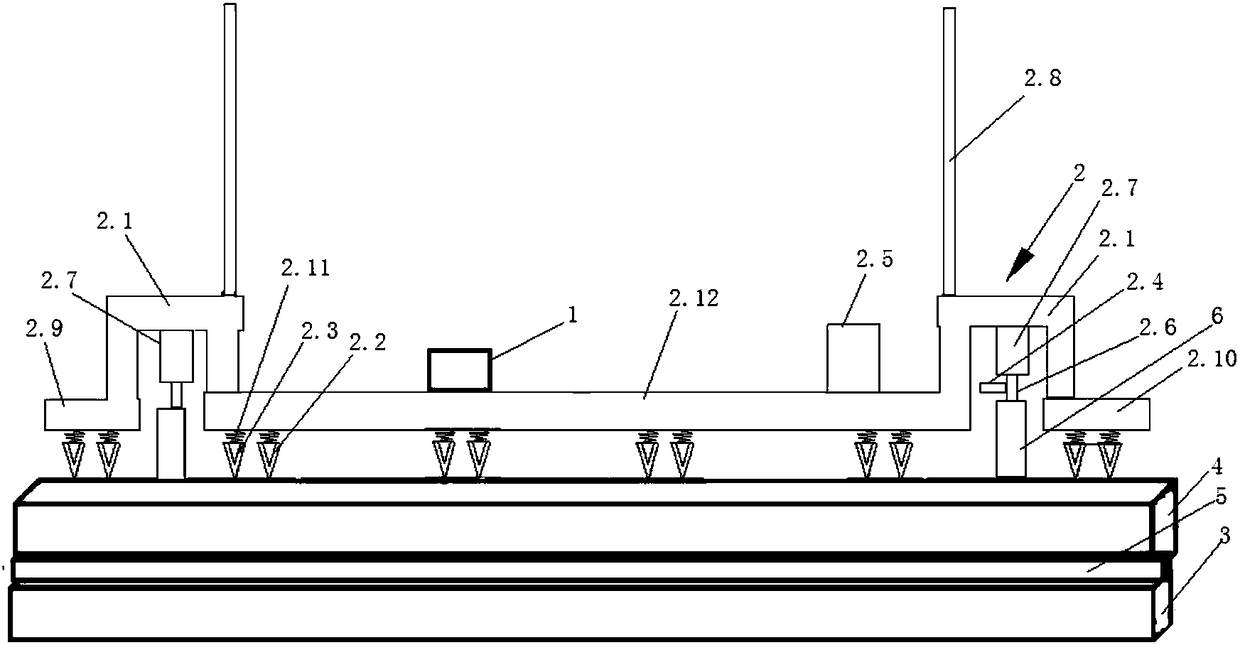

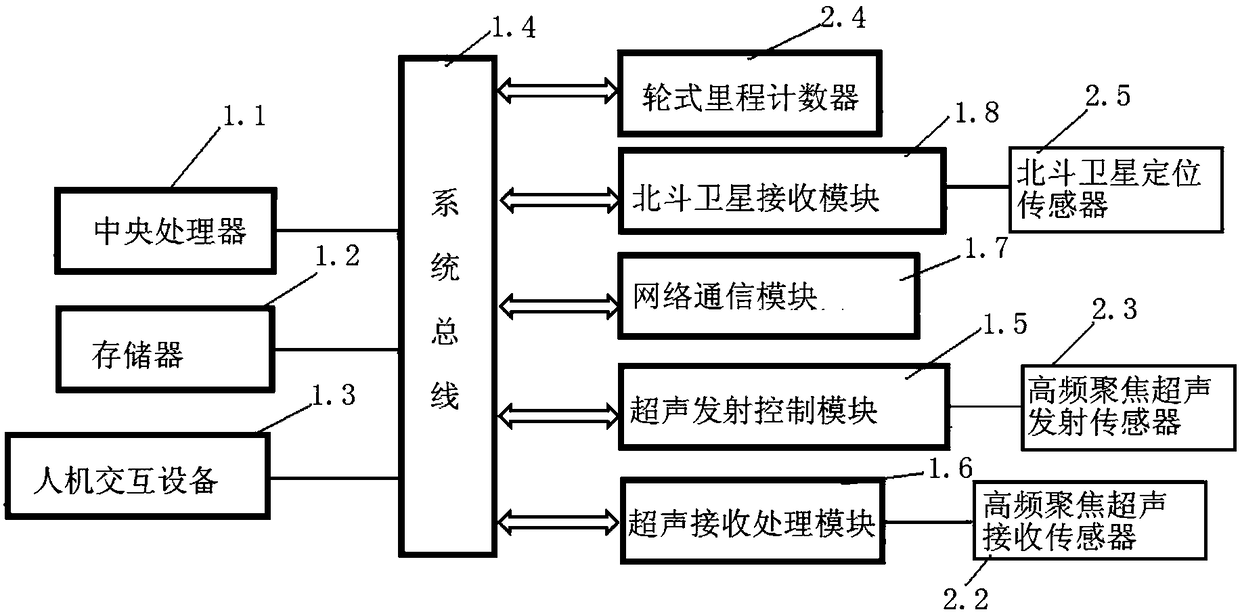

[0025] A CRTSⅡ type ballastless track mortar bonding quality detection equipment of the present invention, such as figure 1 and 2 As shown, it includes a host 1 and a detection vehicle 2, the host 1 includes a central processing unit 1.1, an ultrasonic emission control module 1.5, an ultrasonic reception processing module 1.6, and a network communication module 1.7 (4G network communication module); the detection vehicle 2 includes a detection Vehicle floor 2.12, inspection vehicle left panel 2.9 and inspection vehicle right panel 2.10, wheel mileage counter 2.4, rail wheel assembly 2.6, two hydraulic rods 2.7, two brackets 2.1 and multiple high-frequency focused ultrasonic transceiver sensor groups, Wherein, the left side panel 2.9 of the testing vehicle and the right side panel 2.10 of the testing vehicle are fixedly arranged on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com