Constant-force pressing device and method for organic glass bonding

A technology of plexiglass and pressing device, which is applied in the field of tooling and fixtures, and can solve problems such as parts that do not meet quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

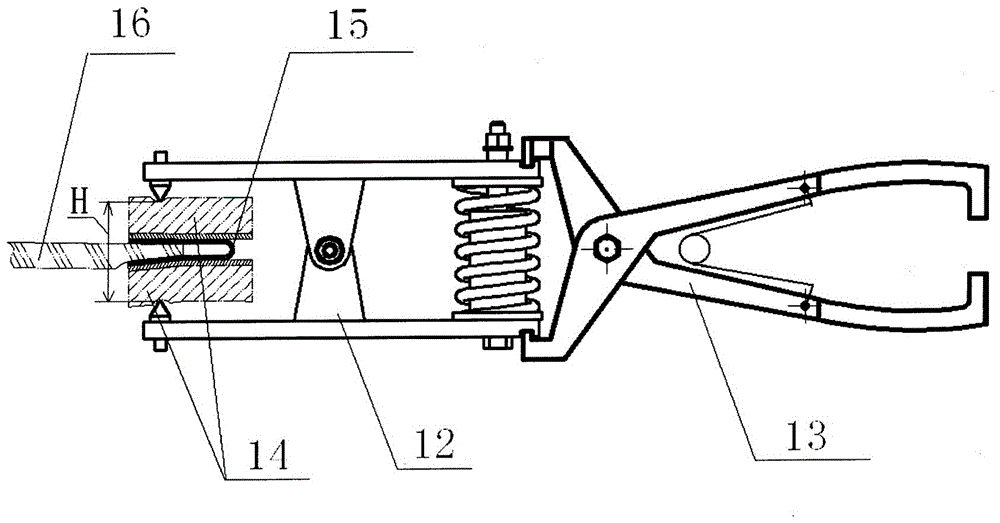

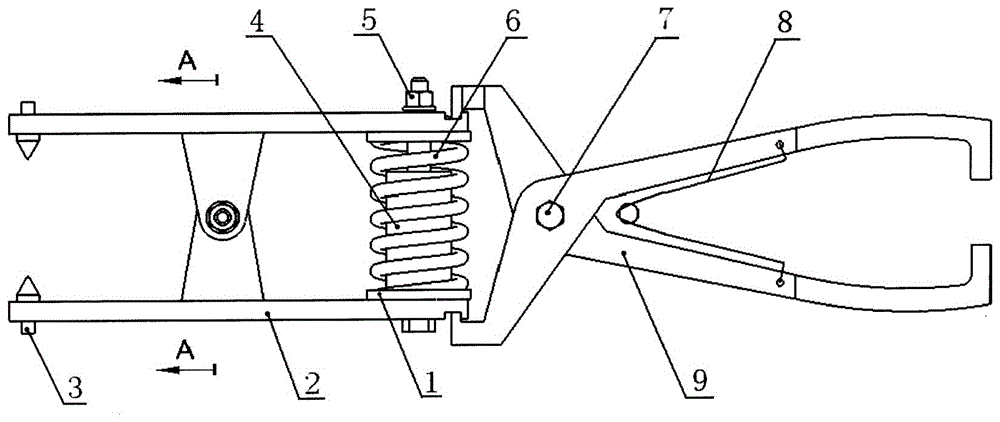

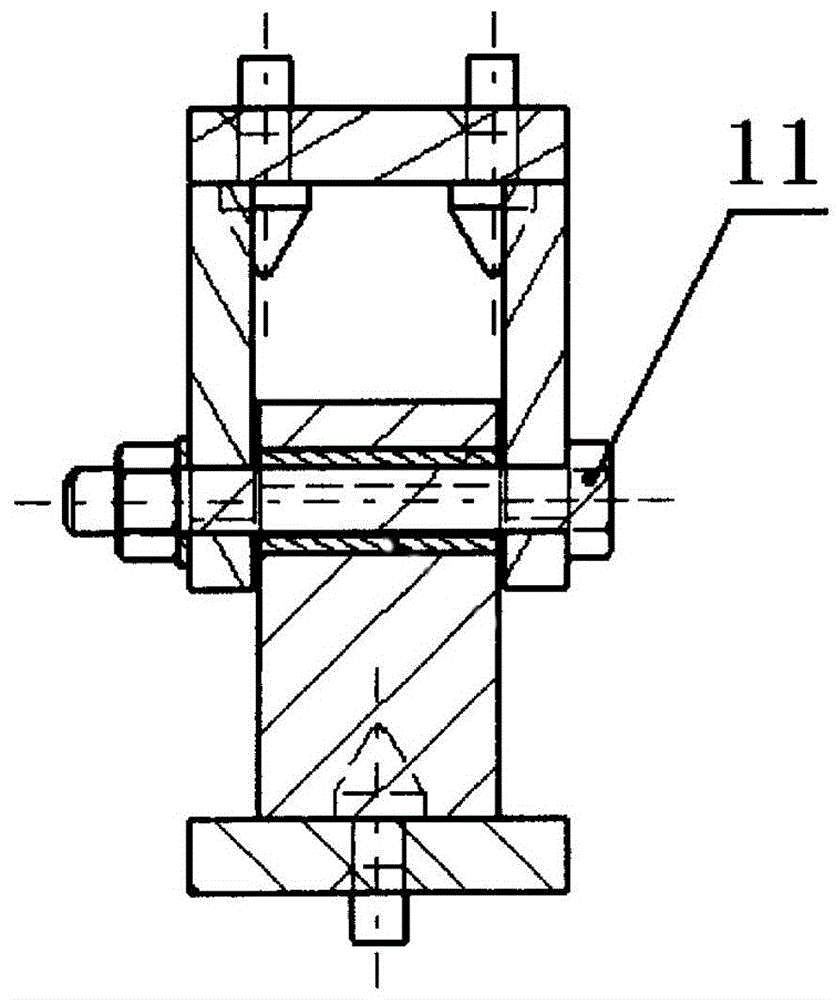

[0022] Such as Figure 1 to Figure 5 As shown, a constant force pressing device for plexiglass bonding is composed of a constant force clamp 12 and an installation clamp 13, wherein the constant force clamp 12 is composed of two brackets 2 arranged up and down, and the two brackets 2 The middle is connected by a rotating shaft 11, and the end of one of the brackets 2 is provided with a bushing 4, the inner cavity of the bushing 4 passes through the pin shaft 5, and the two ends of the pin shaft 5 are movably connected with the corresponding bracket 2, and the bushing 4 A spring 6 is arranged coaxially on the top, one end of the spring 6 is limited on the surface of one of the brackets 2 by the washer 1, and the other end of the spring 6 is limited on the surface of the other bracket 2 by the washer 1; at the outer ends of the two brackets 2 The parts are connected with the installation clamp 13, and the installation clamp 13 and the spring 6 are located at the same side end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com