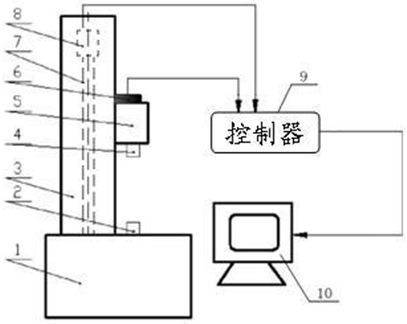

Curve peeling fixture and braided bearing gasket curve bonding quality testing method and system thereof

A technology of bonding quality and testing method, applied in the field of tribology, to achieve the effect of enhanced operability, convenient use and accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

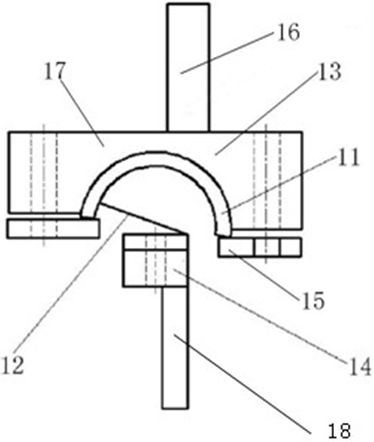

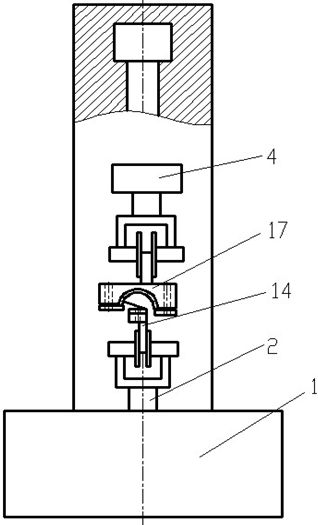

[0033] 1. Surface peeling fixture

[0034] Surface peeling fixtures such as figure 2As shown, take the example of peeling the braided liner from the inner surface of the spherical plain bearing outer ring. The curved surface peeling jig includes an upper jig 13 and a lower jig 14. The upper jig 13 is used to clamp the spherical plain bearing outer ring 11, and the lower jig 14 It is used to clamp the braided liner 12 located on the inner surface of the outer ring of the spherical plain bearing. The upper clamp 13 includes a clamp body 17 and a positioning plate 15. The bottom of the clamp body 17 is provided with an arc groove of 160°-180°. The arc The two ends of the notch of the arc-shaped groove are provided with a positioning plate 15, which is used to fix the object to be peeled off on the curved surface between the arc-shaped groove and the positioning plate. The positions of the two ends of the arc-shaped groove are different in height, and the function is: the bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com