A water seal tank and dry quenching furnace

A technology of water-sealed tank and dry quenching furnace, which is applied in the field of dry quenching and coking, and can solve problems such as affecting normal production operations, occupying cooling space, and increasing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

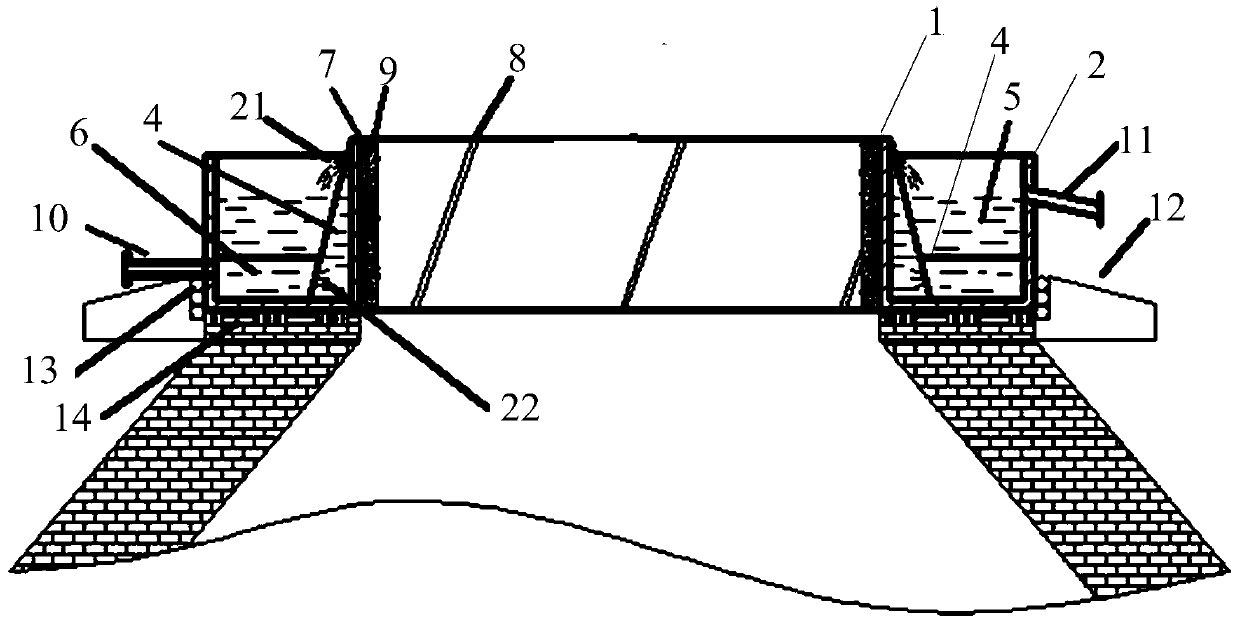

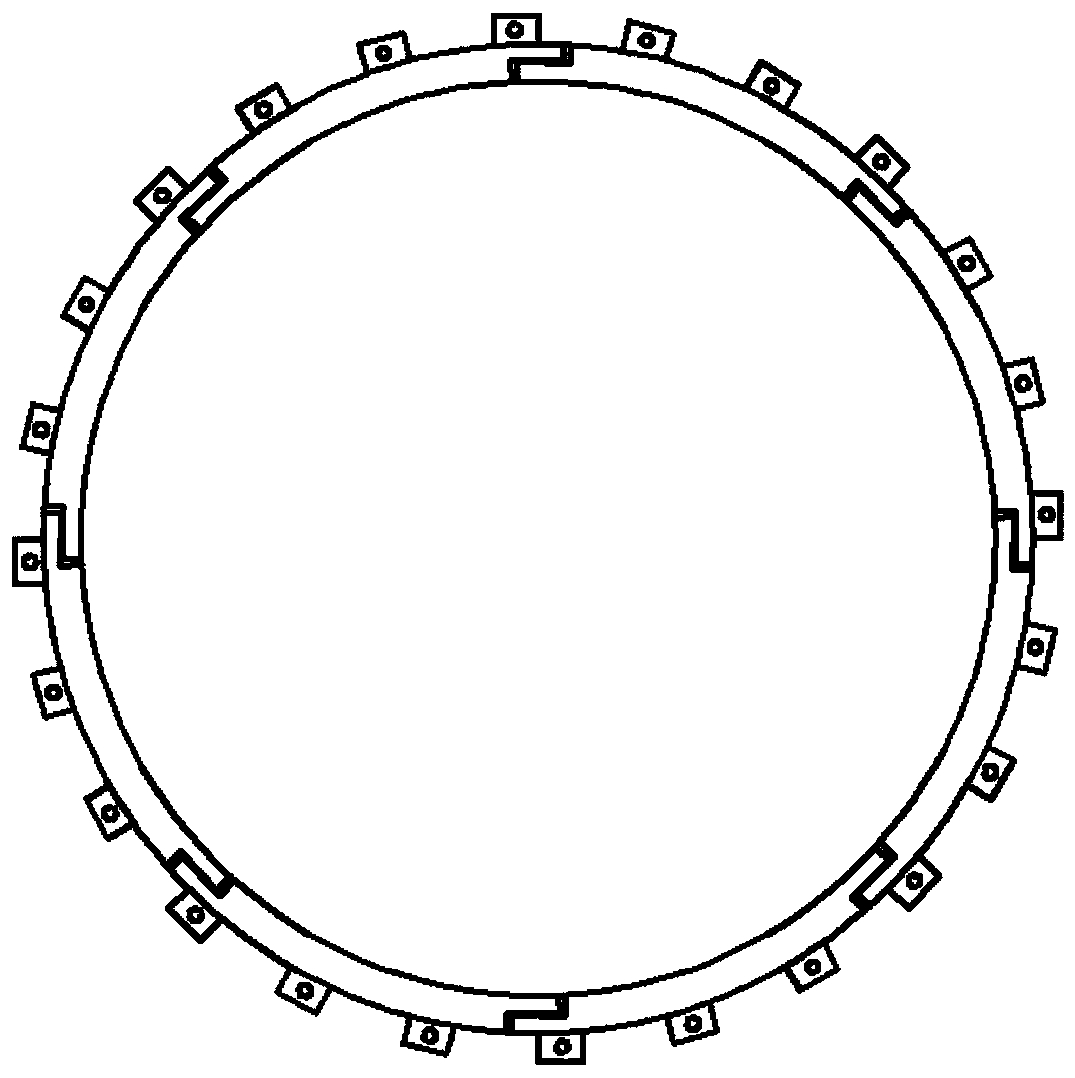

[0028] This embodiment provides a water seal tank, such as figure 1 As shown, the water seal tank includes: the first tank body 1, the isolation compartment 2, the second tank body 3, the isolation plate 4, the first cooling compartment 5 and the second cooling compartment 6; wherein,

[0029] An isolation compartment 2 is installed on the outside of the first tank body 1 ; the isolation compartment 2 is a sealed compartment for cooling the first tank body 1 . In this embodiment, the shape of the cofferdam 2 is a cone, but of course it can also be in other shapes, which are not limited here.

[0030] A plurality of overflow outlets 21 are provided on the upper side of the isolation compartment 2 , and a plurality of through holes 22 are provided on the bottom of the isolation compartment 2 ; the bottom of the isolation compartment 2 is connected to the isolation plate 4 by welding. The bottom width of the cofferdam 2 is 50-80mm, and the height is 40-10mm. Here, the shape of ...

Embodiment 2

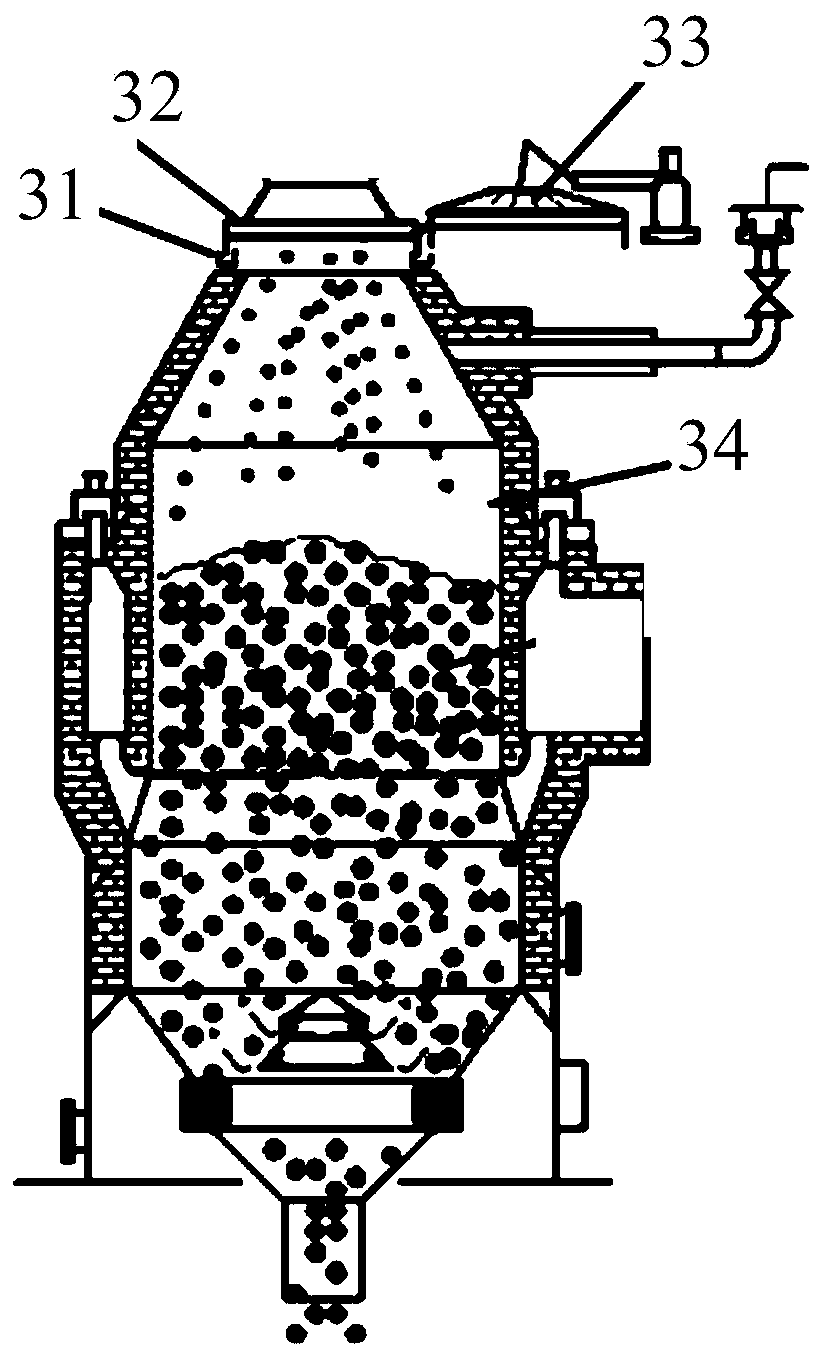

[0041] Corresponding to Embodiment 1, this embodiment also provides a dry quenching furnace, see image 3 , the CDQ furnace includes the water seal tank 31 provided in Embodiment 1, the furnace cover 32, the movable sealing cover 33 and the CDQ furnace body 34; wherein,

[0042] When charging the CDQ furnace body 34 with coke, the coke charging chute is aligned with the furnace roof and the movable sealing cover 33 cooperates with the water seal groove 31 on the furnace top to form a sealed state. After the coke charging is completed, the furnace cover 32 and the water seal groove 31 cooperates to form an airtight state, preventing dust from overflowing and air from leaking into the CDQ furnace body 34.

[0043] like figure 1 As shown, the water seal tank includes: the first tank body 1, the isolation compartment 2, the second tank body 3, the isolation plate 4, the first cooling compartment 5 and the second cooling compartment 6; wherein,

[0044] An isolation compartment 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com