Runner blade convoluting mechanism

A runner blade and blade technology, which is applied in the field of runner blade gyratory mechanism, can solve the problem of high leakage value between the blade and the inner wall of the stator, and achieve the effects of improving service life, improving energy efficiency and stabilizing movement structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

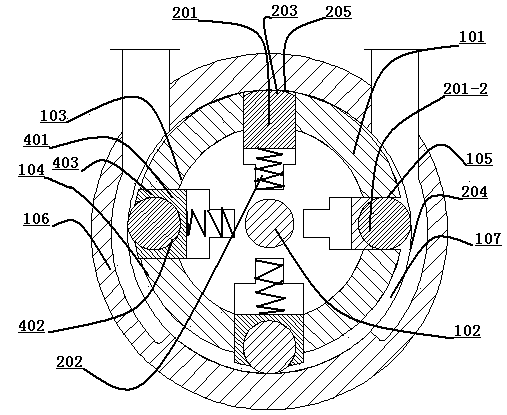

[0039] Such as figure 1 As shown, a runner 103 is installed on the drive shaft 102 of the rotor 101, four sliding blade grooves 105 are axially opened on the column 104 of the runner 103, and the runner 103 bearing support is eccentrically mounted on the cylinder 107 of the stator 106. in. The blade 201 is installed in the sliding blade groove 105 of the runner 103. The blade 201 is under the action of the centrifugal force of the rotation of the runner 103 or the elastic force of the spring 202 installed in the sliding blade groove 105. 203 is in line contact with the inner circular arc wall 204 of the cylinder 107. The rotor 101 rotates, and the outer arc surface 203 at the top of the blade 201 moves and circulates in contact with the inner arc wall surface 204 of the cylinder 107, and an arc surface 205 is formed on the outer arc surface 203 of the blade 201. The contact area of the arc surface 205 is The size is proportional to the arc diameter of the outer arc surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com