Pyrolyzation, gasification and carbonization device for producing reclaimed oil by utilizing waste

A technology of pyrolysis gasification and carbonization device, which can be used in gasification process, preparation of liquid hydrocarbon mixture, treatment of hydrocarbon oil, etc., and can solve the problems of fire danger, poor thermal efficiency, high temperature thermal shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

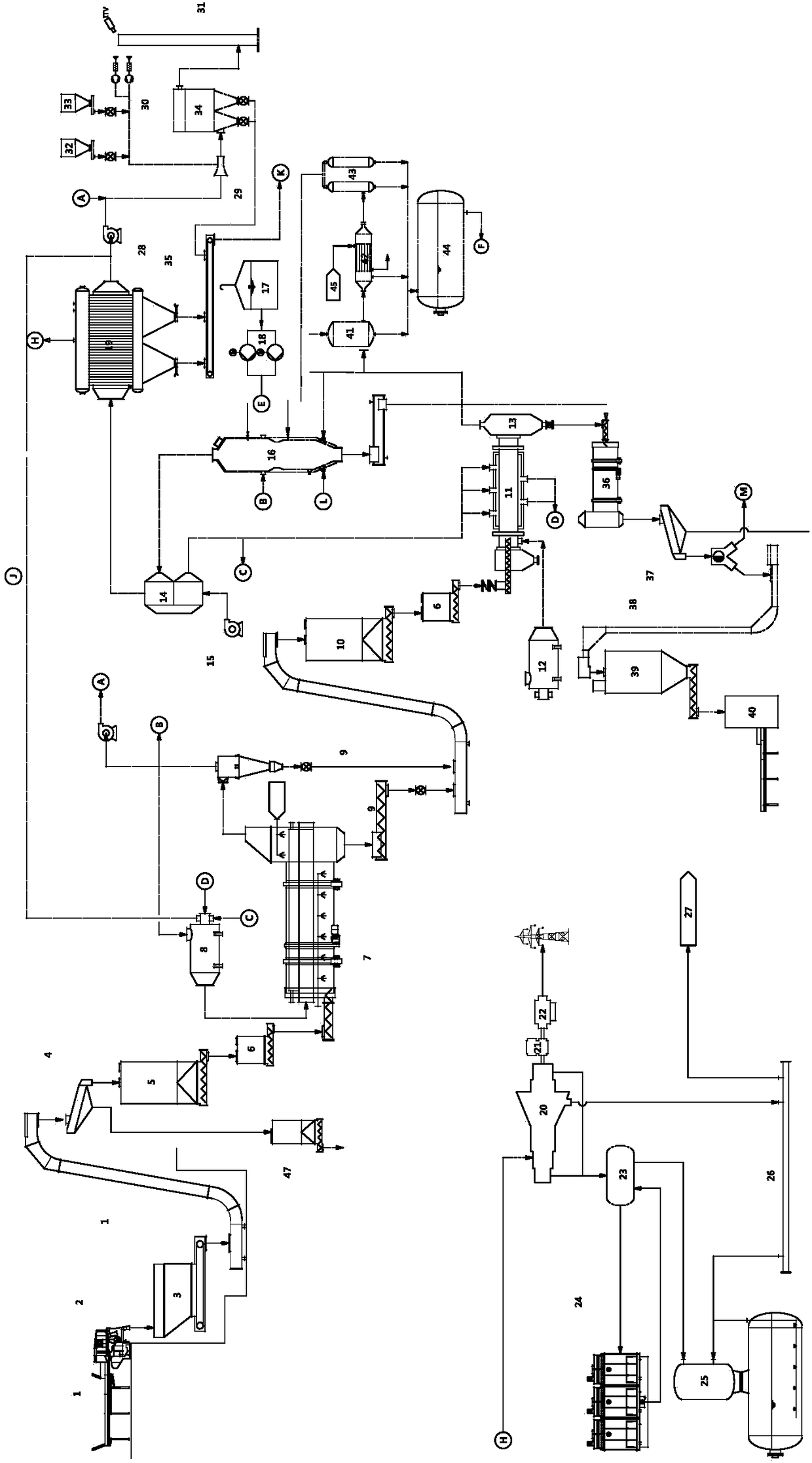

[0036] The following with attached figure 1 A device for producing regenerated oil by pyrolysis, gasification and carbonization of waste according to the present invention will be further described in detail.

[0037] A device of the present invention that utilizes waste pyrolysis, gasification and carbonization to produce recycled oil, please refer to figure 1 The relevant diagrams in the figure include raw material supply system, raw material pretreatment system, thermal decomposition and carbonization device, combustion gasification device, waste heat recovery and utilization system, carbon recovery system and regenerated oil preparation and collection system. The raw material pretreatment system is connected, the raw material pretreatment system is connected with the thermal decomposition carbonization device, the thermal decomposition carbonization device is connected with the regeneration oil preparation and collection system, and the combustion gasification device is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com