A self-gravity fluidized bed piping system for powder curing agent transportation and its application method

A fluidized bed and curing agent technology, used in conveyors, transportation and packaging, conveying bulk materials, etc., can solve problems such as blockage of conveying pipelines, easy blockage of feeding channels, and inability to add curing agent, so as to improve construction efficiency and improve efficiency. The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

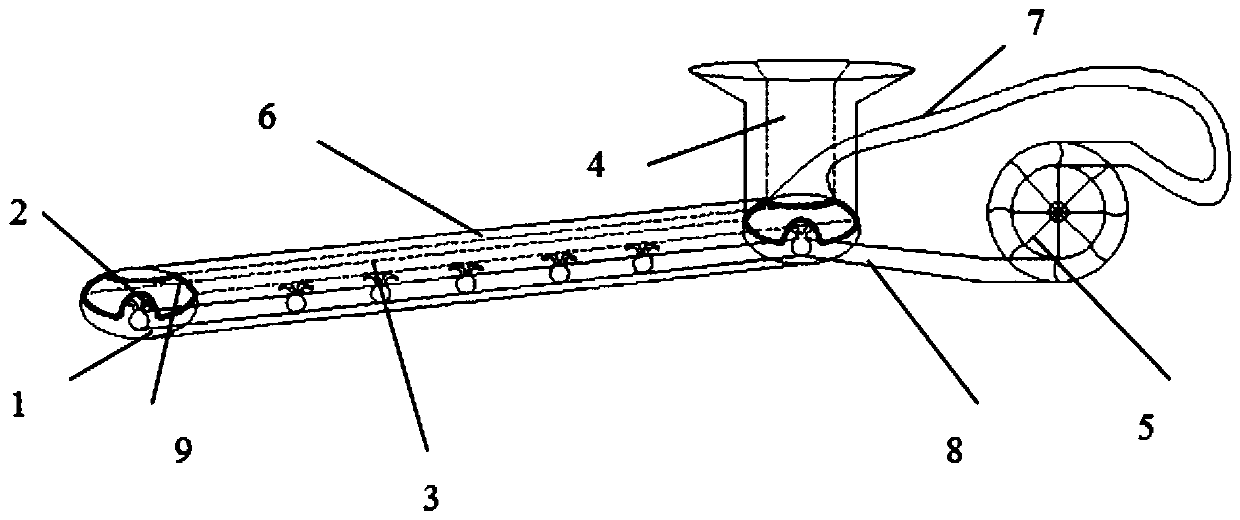

[0018] The present invention proposes a self-gravity fluidized bed pipeline system for powder solidifying agent transportation and its use method. Its overall structure includes three parts: fluidized bed pipeline, feeding hopper, and air circulation compressor.

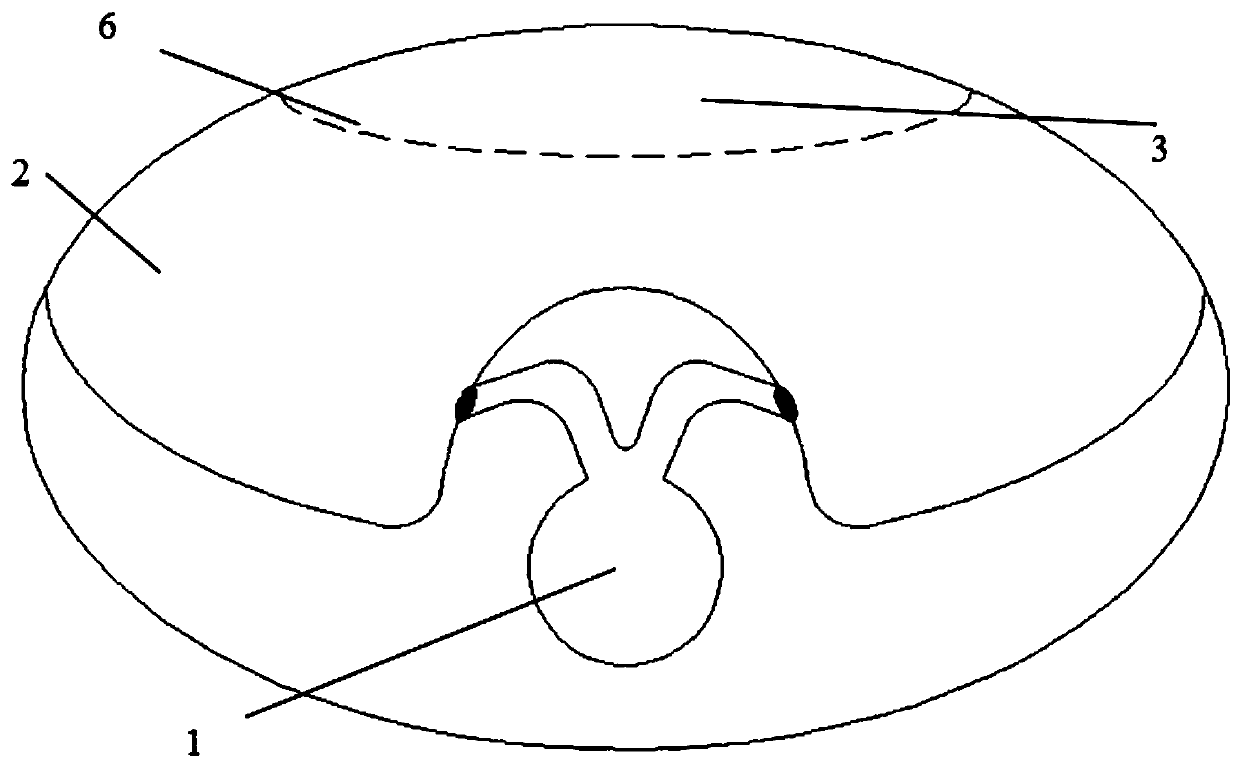

[0019] The fluidized bed pipeline in the structure is a pipeline structure with openings at both ends. The fluidized bed pipeline is divided into 3 chambers along the length of the pipeline. From bottom to top, they are the inlet channel 1, the medium delivery channel 2, and the gas recovery channel 3. One end of the air intake channel is connected to the exhaust port 8 of the air circulation compressor 5, and one end is open. The intake channel 1 has two manifolds at intervals, and the curved holes are opened in the medium conveying channel. The orifice is downward, and the medium conveying channel 2 is located in the middle layer of the fluidized bed pipeline, the walls of the cavity are coated with Teflon material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com