A kind of amino acid@cu-btc composite adsorbent and its preparation method

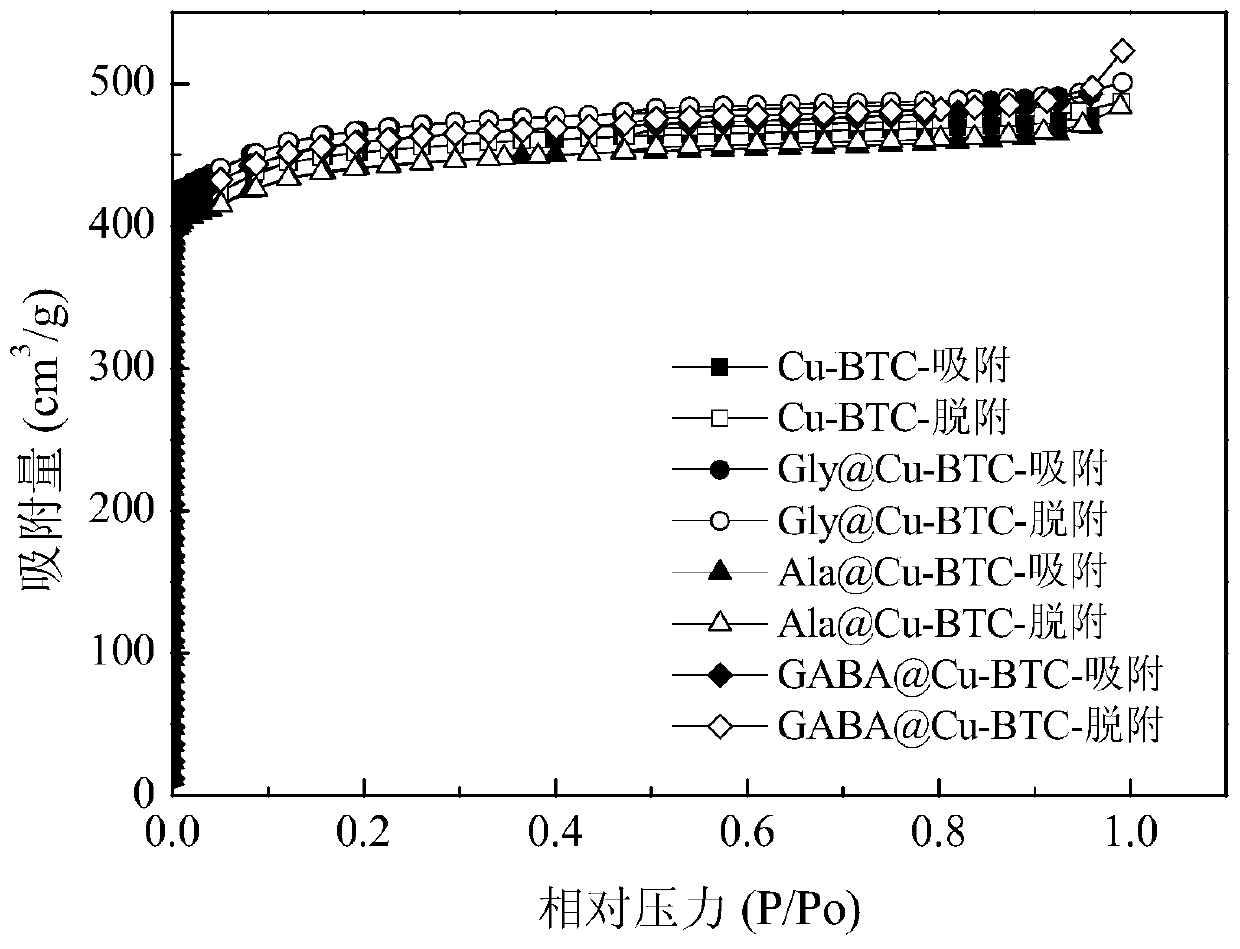

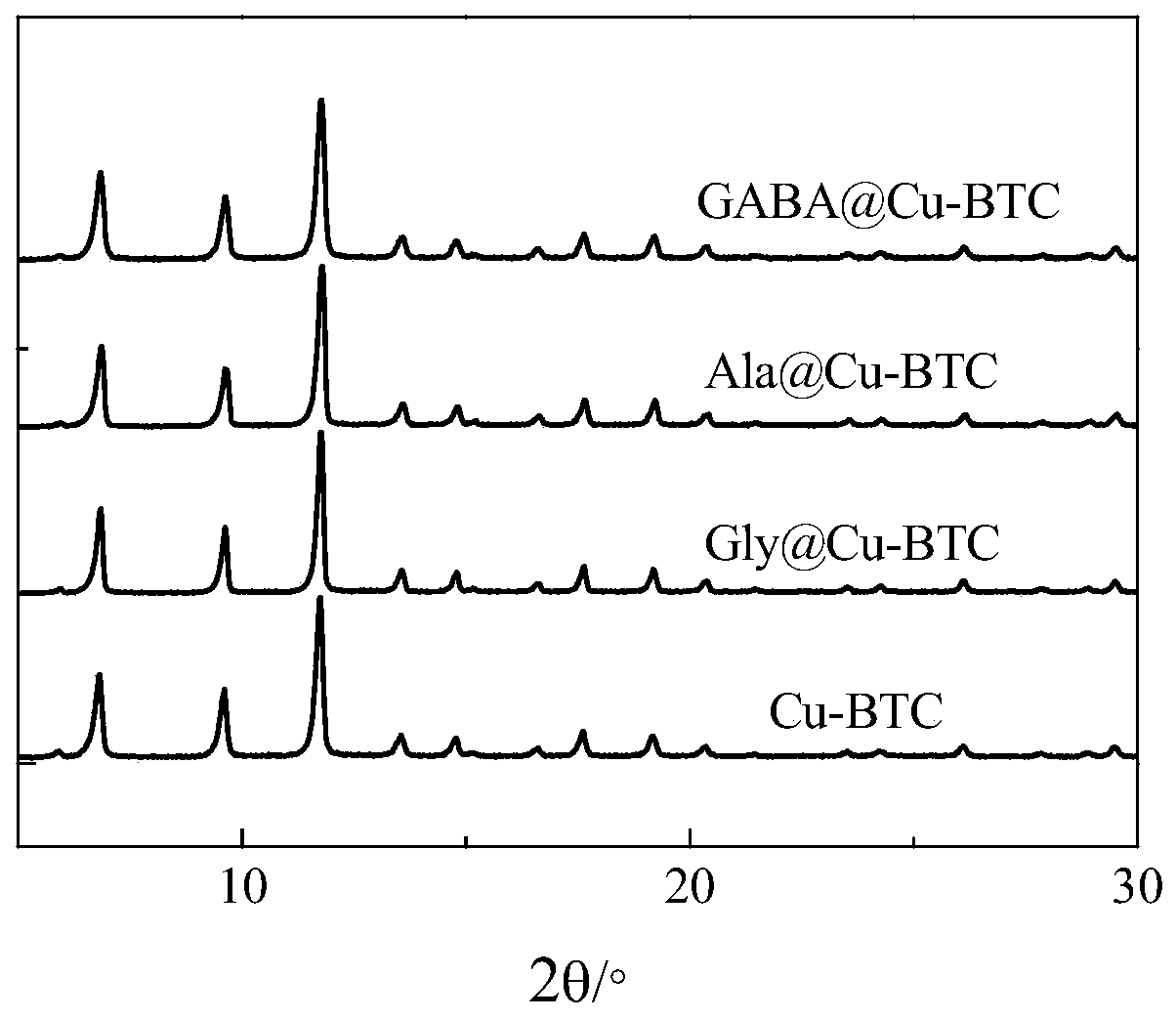

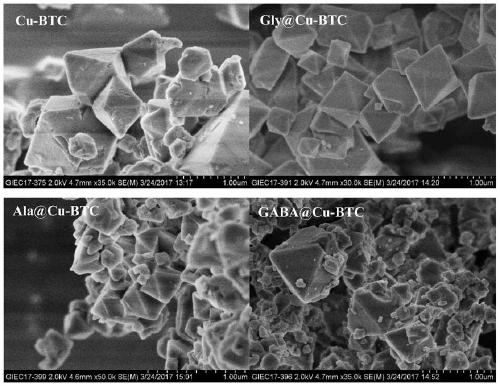

A compound adsorption and amino acid technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of no adsorption performance, etc., and achieve the effect of short reaction time, good repeatability and high CO2 adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Nano ZnO (3.6mmol, n 1 ) dissolved in deionized water (8ml, n 2 ), after ultrasonic dispersion for 10min, DMF (16ml, n 3 ), to obtain a ZnO nanoslurry solution; the Cu(NO 3 ) 2 ·3H 2 O(7.2mmol, n 4 ) and Gly (2.16mmol, n 5 ) dissolved in deionized water (8ml, n 6 ), to get Cu(NO 3 ) 2 and Gly mixture; Trimellitic acid (3.2mmol, n 7 ) dissolved in ethanol (16ml, n 8 ), obtain trimesic acid solution; wherein the consumption ratio of various substances is (n 2 +n 6 ):n 3 :n 8 = 1:1:1; n 1 :n 4 =1:2.

[0031] (2) Cu(NO) obtained in step (1) 3 ) 2 Add the mixed solution of ZnO and Gly into the ZnO nano slurry solution, stir and mix evenly, then add trimesic acid solution, stir and react for 5-10 minutes to obtain a blue solution containing the reaction product, and pass the solution through an organic filter with an average pore size of 0.45 μm After filtration, the solid product was sequentially soaked in methanol, centrifuged and dried to obtain a bl...

Embodiment 2

[0034] (1) Nano ZnO (5.76mmol, n 1 ) dissolved in deionized water (8ml, n 2 ), after ultrasonic dispersion for 10min, DMF (19ml, n 3 ), to obtain a ZnO nanoslurry solution; the Cu(NO 3 ) 2 ·3H 2 O(7.2mmol, n 4 ) and β-Ala (2.88mmol, n 5 ) dissolved in deionized water (8ml.n 6 ), to get Cu(NO 3 ) 2 and β-Ala mixture; Trimellitic acid (3.2mmol, n 7 ) dissolved in ethanol (16ml, n 8 ), obtain trimesic acid solution; wherein the consumption ratio of various substances is (n 2 +n 6 ):n 3 :n 8 =1:1.2:1; n1:n4=1:1.25.

[0035] (2) Cu(NO) obtained in step (1) 3 ) 2 Add the mixed liquid with β-Ala to the ZnO nano slurry solution, stir and mix evenly, then add trimesic acid solution, stir and react for 5-10min to obtain a blue solution containing the reaction product, and use the organic solution with an average pore size of 0.45μm filter membrane, and the solid product was sequentially soaked in methanol, centrifuged and dried to obtain a blue solid powder.

[0036] (...

Embodiment 3

[0038] Nano ZnO (3.6mmol, n 1 ) dissolved in deionized water (8ml, n 2 ), after ultrasonic dispersion for 10min, DMF (16ml, n 3 ), to obtain a ZnO nanoslurry solution; the Cu(NO 3 ) 2 ·3H 2 O(7.2mmol, n 4 ) and GABA (2.88mmol, n 5 ) dissolved in deionized water (8ml, n 6 ), to get Cu(NO 3 ) 2 and GABA mixture; Trimellitic acid (3.2mmol, n 7 ) dissolved in ethanol (21ml, n 8 ), obtain trimesic acid solution; wherein the consumption ratio of various substances is (n 2 +n 6 ):n 3 :n 8 = 1:1:1.3; n 1 :n 4 =1:2.

[0039] (2) Cu(NO) obtained in step (1) 3 ) 2 Add the mixed solution of GABA and ZnO into the nano-slurry ZnO solution, stir and mix evenly, then add trimesic acid solution, stir and react for 5-10 minutes to obtain a blue solution containing the reaction product, and pass the solution through an organic filter with an average pore size of 0.45 μm After filtration, the solid product was sequentially soaked in methanol, centrifuged and dried to obtain a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com