Squeezing roller device for dry granulator

A dry granulator and squeezing roller technology, applied in the direction of die extrusion granulation, etc., can solve the problems of restricting the scope of application of the dry granulator, difficult to control the automatic gap adjustment of the squeezing roller, and unable to realize automatic gap adjustment. , to achieve the effect of simple structure, precise and controllable speed, and wide range of speed regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

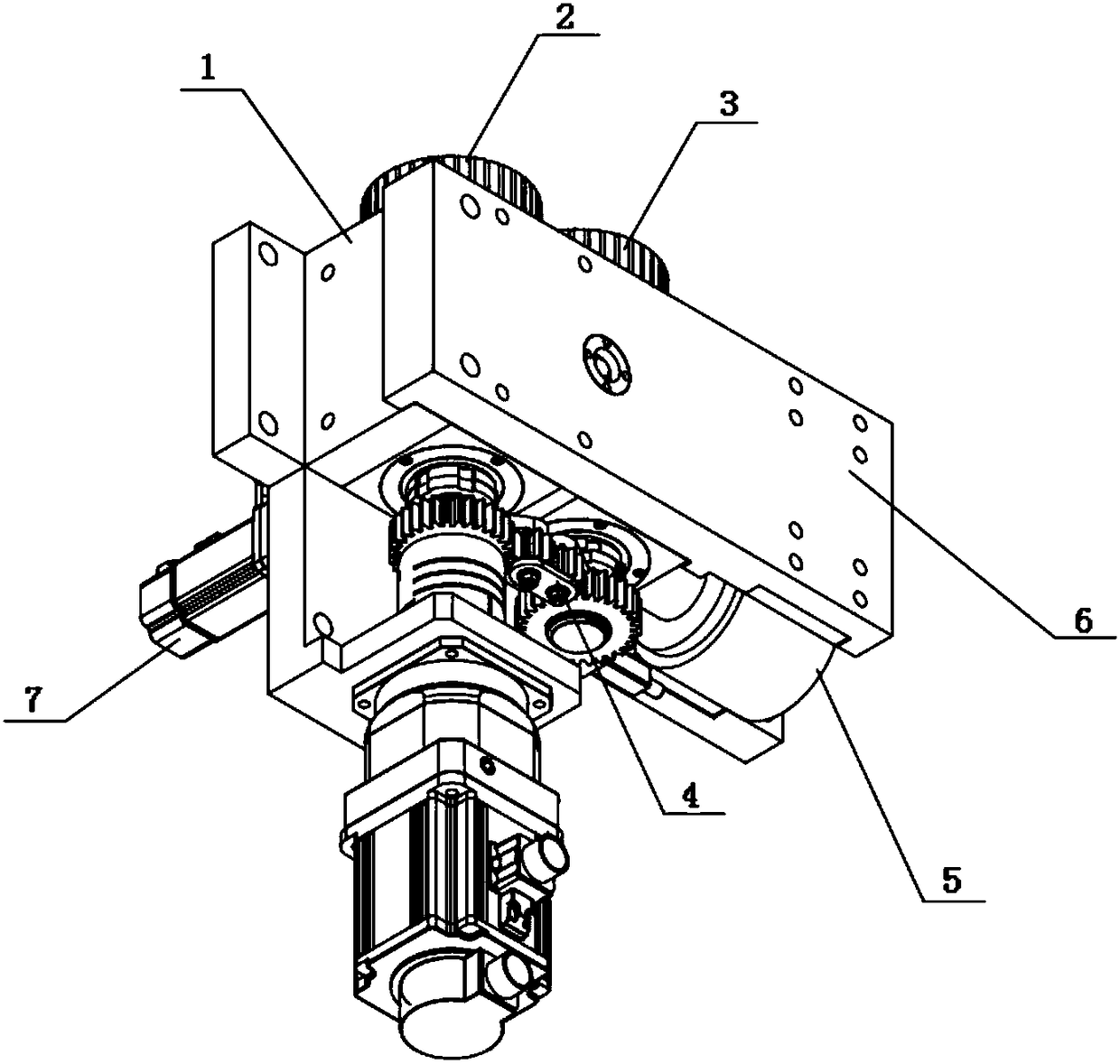

[0036] A squeeze roll device of a dry granulator, such as figure 1 As shown, it includes a seat frame 1, a driving roller device 2, a driven roller device 3, a hanging wheel device 4, a hydraulic push cylinder device 5, an upper cover plate 6 and an automatic gap adjustment device 7.

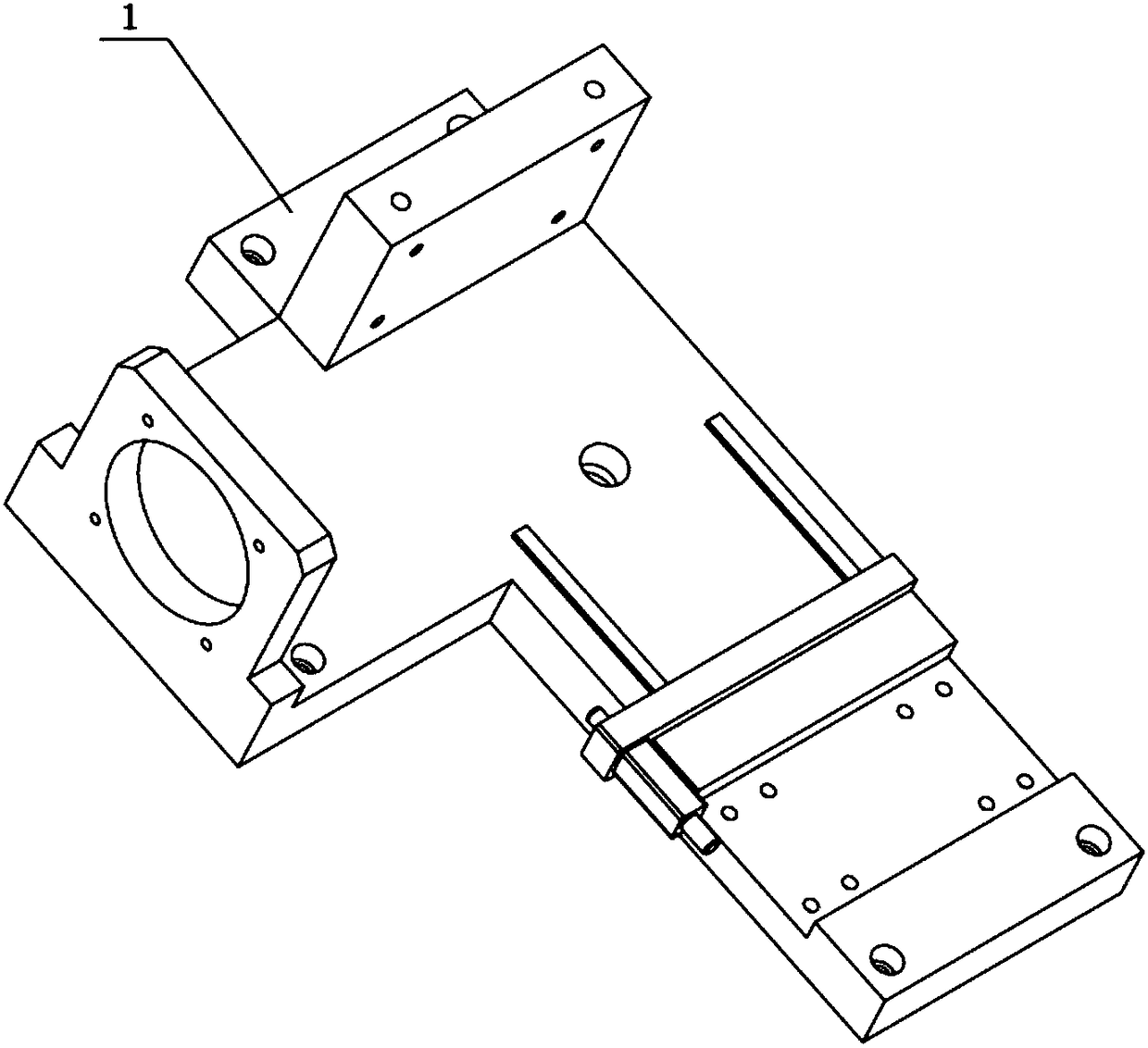

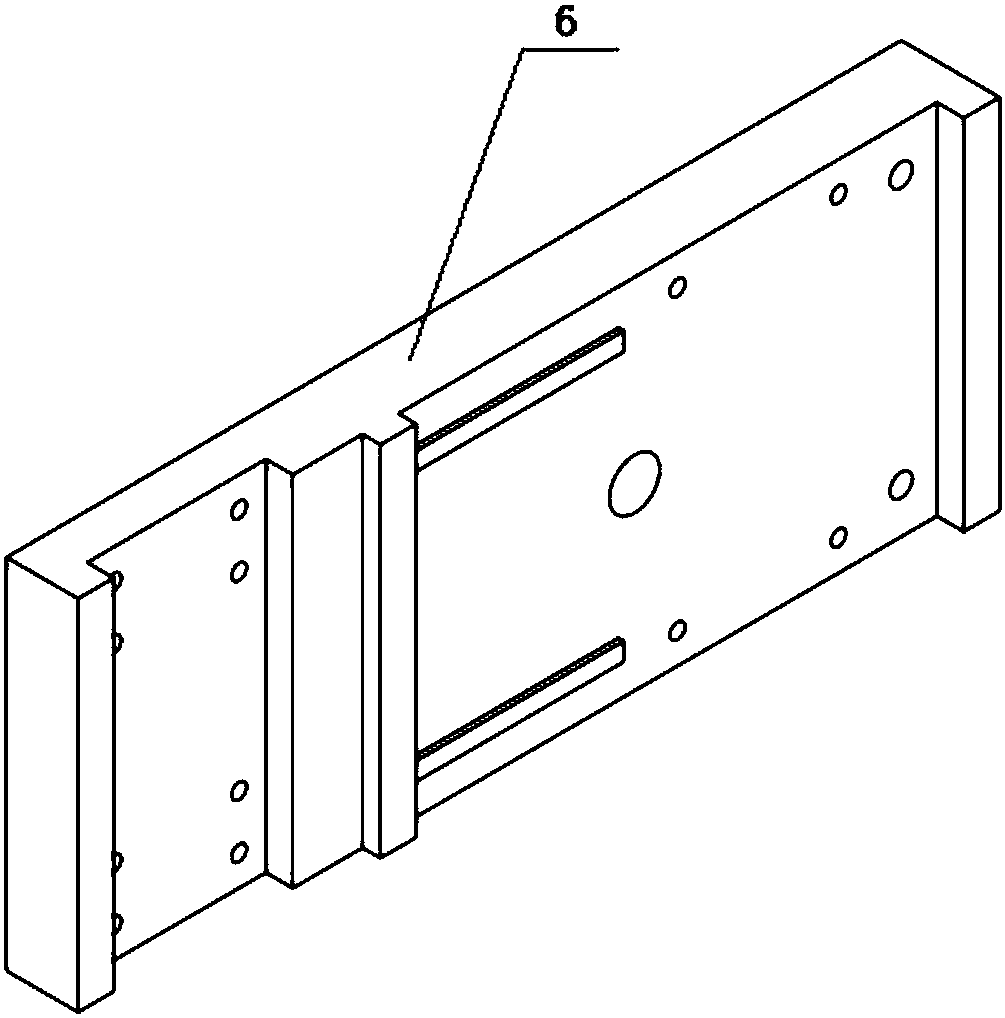

[0037] mount 1 such as figure 2 As shown, the upper cover plate 6 is as image 3 As shown, the driving roller device 2 and the driven roller device 3 are connected through the hanging wheel device 4 and installed between the seat frame 1 and the upper cover plate 6 . An automatic gap adjustment device 7 is installed on the bottom of the seat frame 1, and the back of the driven roller device 3 is offset against ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com