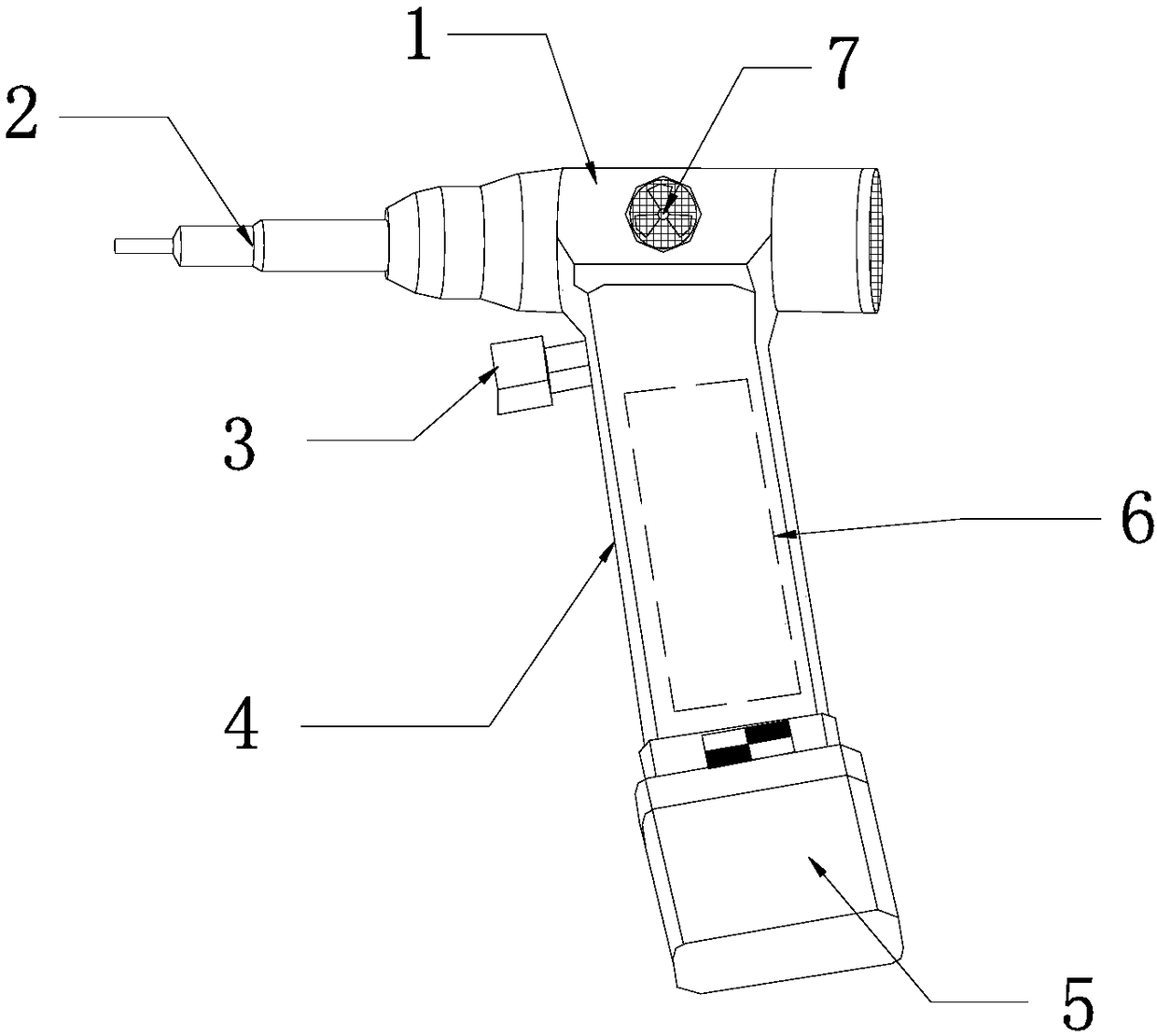

Craniotomy milling cutter with built-in cooling water channel

A cooling water channel and cooling mechanism technology, applied in medical science, surgery, etc., can solve the problem of low rotation speed of craniotomy and milling, and achieve the effect of increasing rotation speed, reducing operation time, and accelerating air circulation and air exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

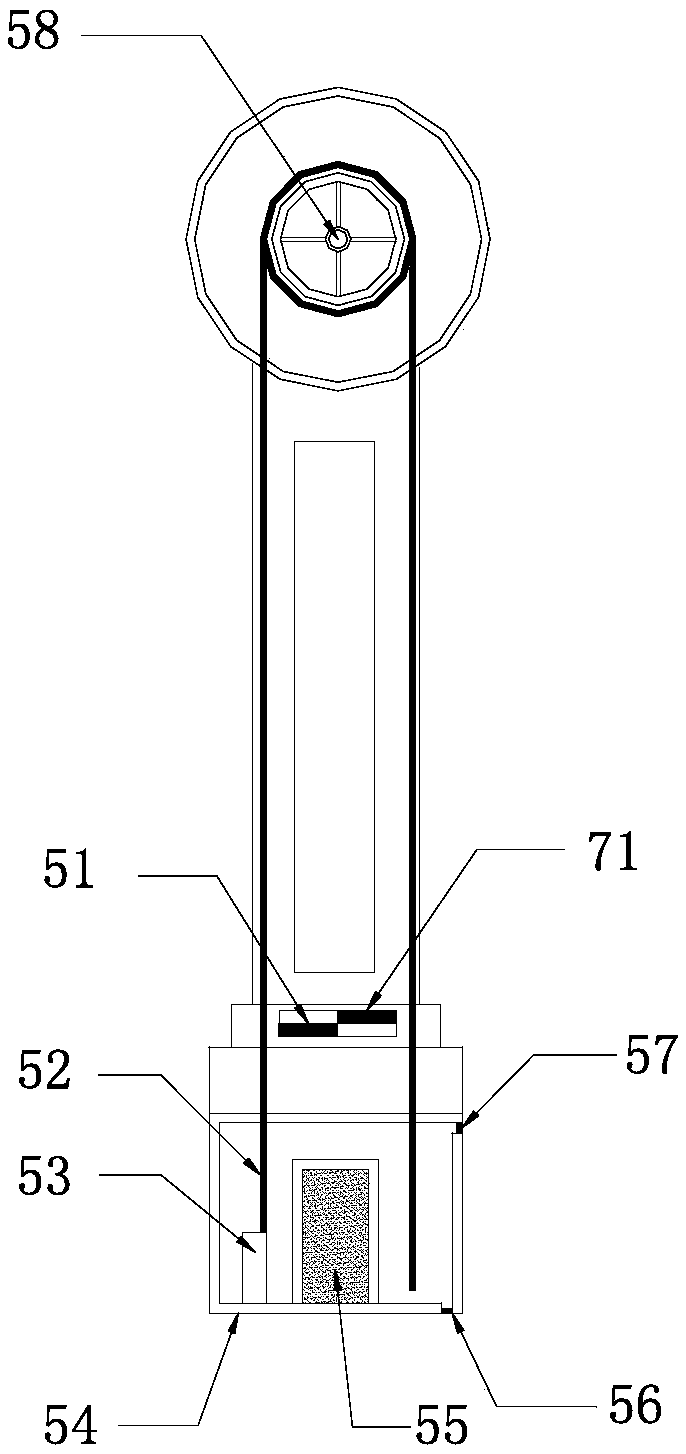

[0020] Specific embodiments: when the present invention is in use, the motor 58 starts to run, the control switch one 51 is turned on, the electric energy of the storage battery 6 is transferred to the micro-water pump 53, the micro-water pump 53 converts the electric energy into mechanical energy, and the micro-water pump 53 transfers the water of the water tank 54 to the heat conduction In the tube 52, water flows in from the front end of the heat transfer tube 52, flows into the water tank 54 from the rear end of the heat transfer tube 52, and takes away the heat generated by the motor 58, and the refrigerator 55 cools down the water in the water tank 54 through the Freon installed inside. , improve the working efficiency of the motor 58, and reduce the operation time by increasing the rotating speed.

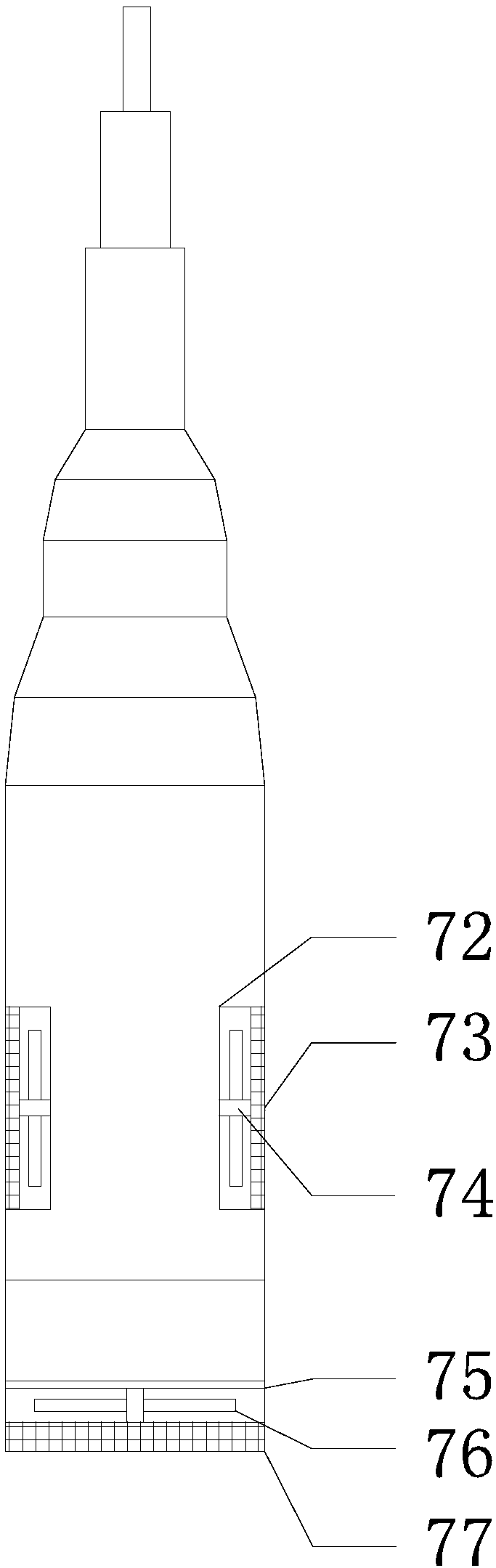

[0021] Open control switch two 71 simultaneously, the intake fan 74 in the fan slot 72 converts electric energy into mechanical energy, and the intake fan 74 starts running, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com