Horizontal cell structure to prevent self-discharge

A horizontal battery and self-discharge technology, which is applied in secondary batteries, lead-acid batteries, secondary battery repair/maintenance, etc., can solve problems such as self-discharge, and achieve the effect of ensuring sealing and avoiding self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

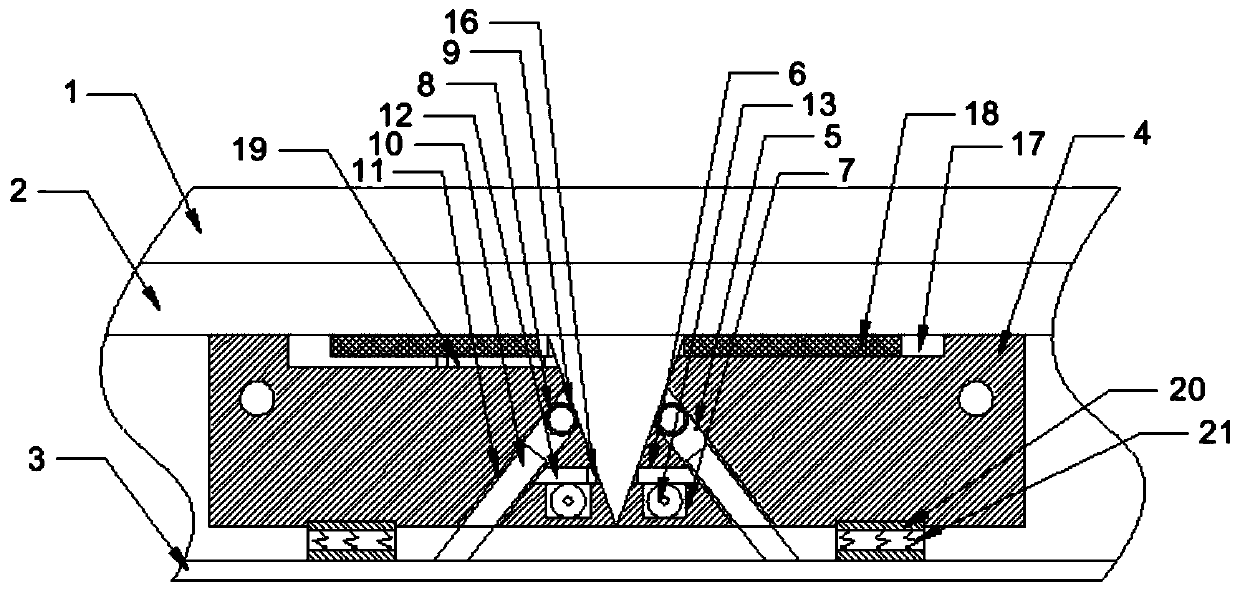

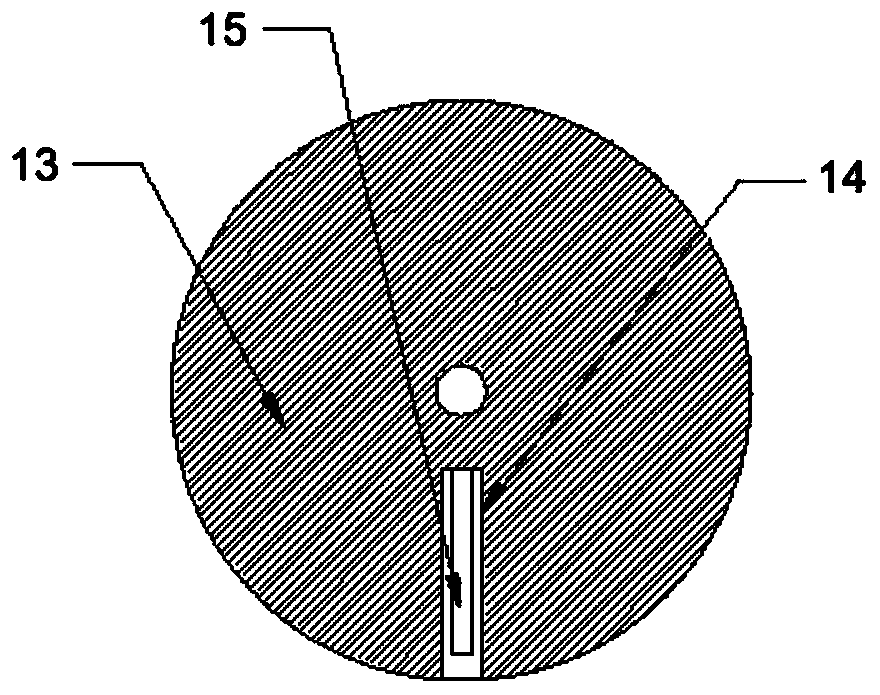

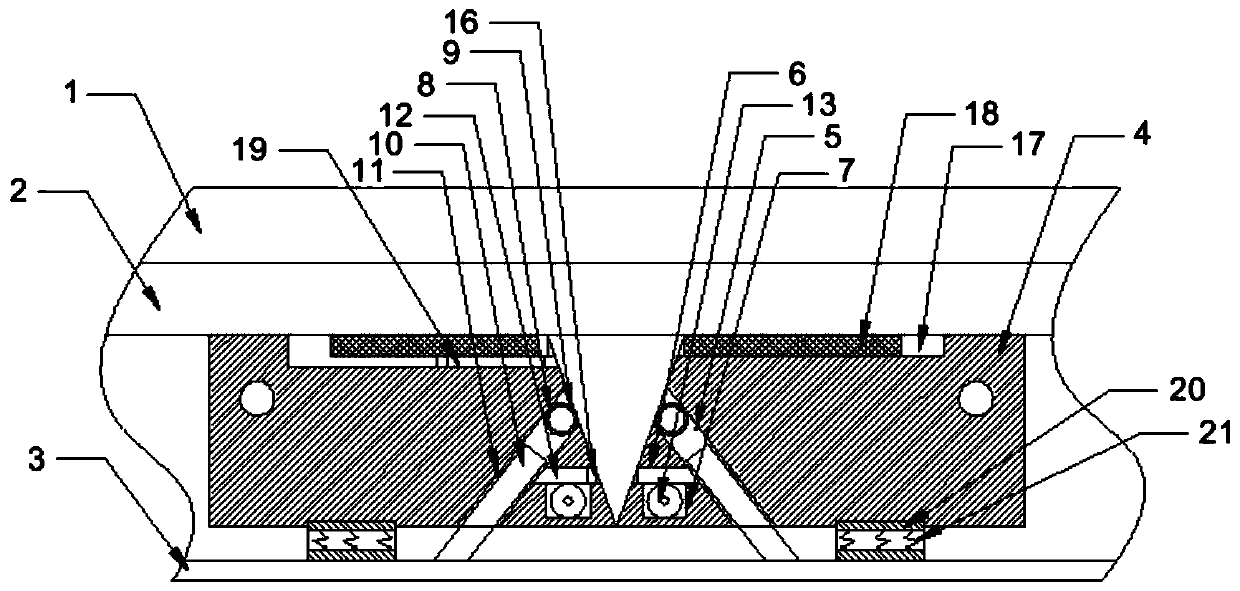

[0016] Further detailed explanation through specific implementation mode below:

[0017] The reference signs in the drawings of the description include: protection tube 1, cement bag 2, elastic layer 3, rocker arm 4, inclined hole 5, transverse groove 6, heating groove 7, water bag 8, water spray hole 9, inclined block 10. First spring 11, metal rack 12, heating gear 13, heating hole 14, heating wire 15, permanent magnet 16, chute 17, buffer net 18, rotating rod 19, sponge block 20, second spring 21.

[0018] The embodiment is basically as attached figure 1 And attached figure 2 Shown: The horizontal battery structure to prevent self-discharge, including the protective tube connected to the horizontal battery, and the inner wall of the protective tube is provided with grooves; the groove is provided with cement bag 2, reinforcement layer and elastic layer in sequence from the inside to the outside 3. There are several outlets on the cement bag 2 .

[0019] The reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com