A slow-wave structure of an angle logarithmically folded slot waveguide

A technology of slow-wave structure and slot waveguide, which is applied to the circuit components of transit-time electronic tubes, can solve the problems of high operating voltage, internal failure, and inability to miniaturize devices, so as to reduce operating voltage, avoid failure, and reduce equipment volume. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

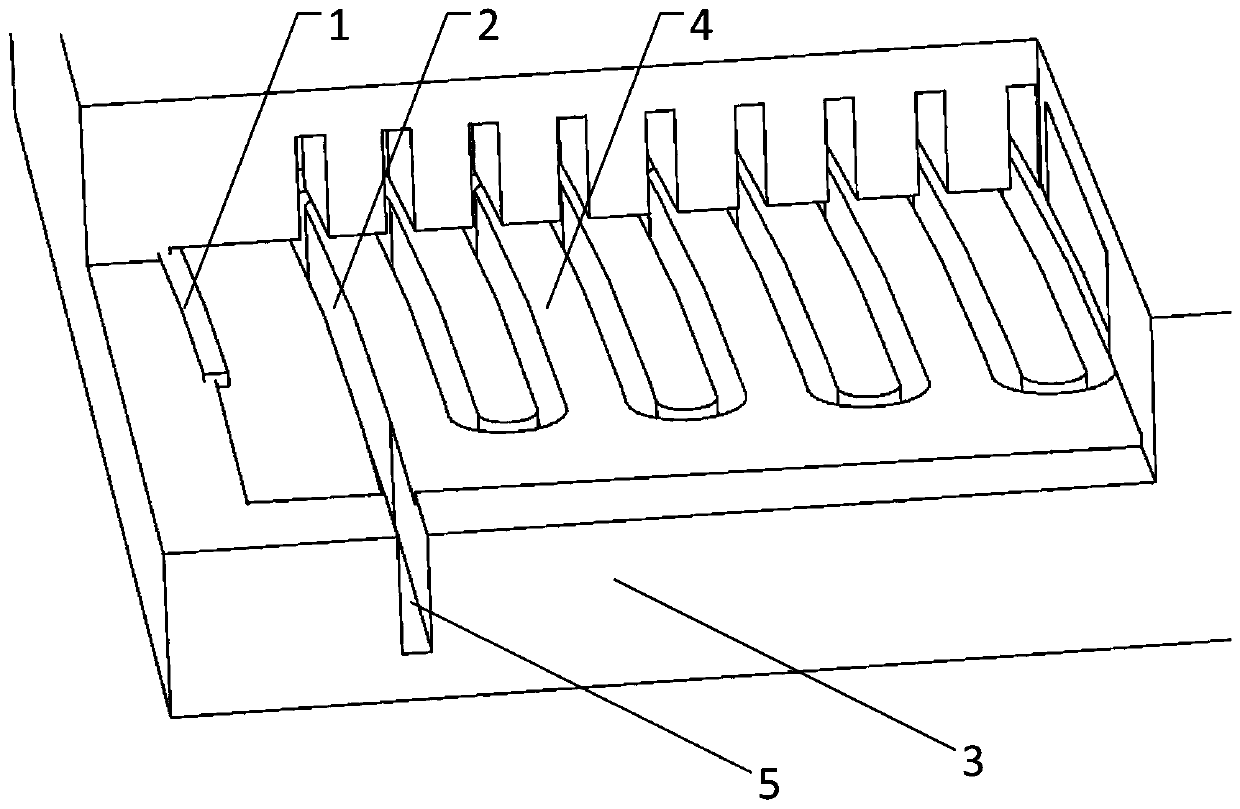

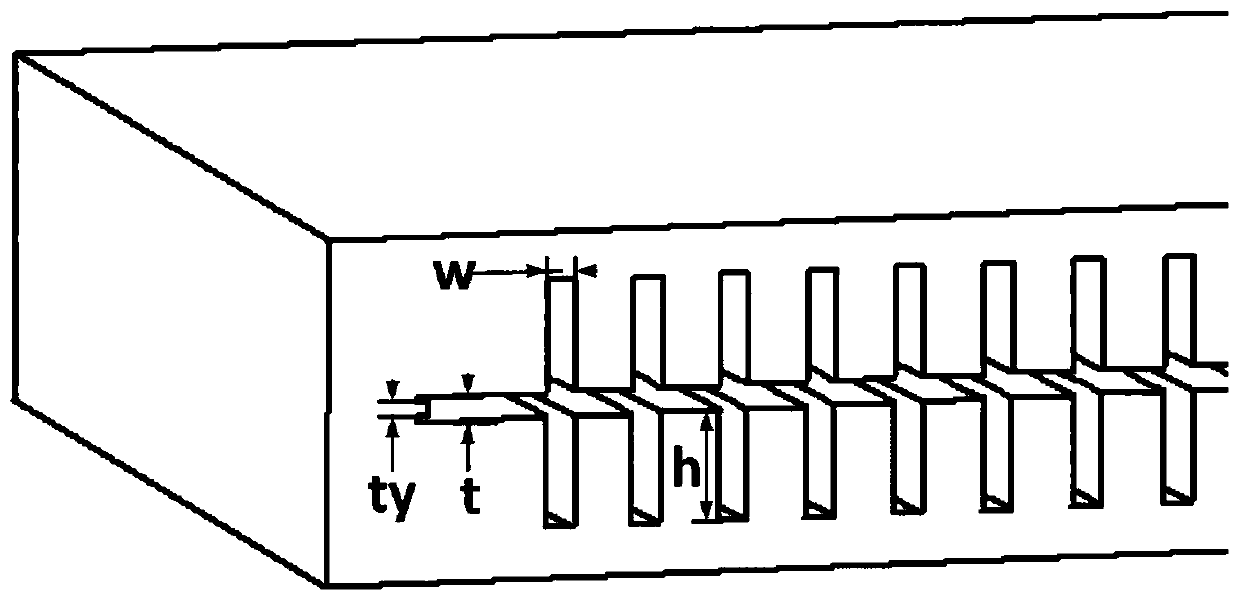

[0035] The cross-section of the angle logarithmic slot waveguide is rectangular, its width W is 0.1 mm, its depth h is 0.3 mm, the thickness t of the radial electron injection channel 4 is 0.08 mm, and its opening angle Greater than slot waveguide opening angle Zhang Jiao Take 4°. The radial emitting surface of the cathode emitter 1 is concentric with the slot waveguide, and the opening angle is arc surface, opening angle It is located at the rightmost end of the radial electron injection channel 4, and its thickness t y It only needs to be smaller than the thickness t of the radial electron injection channel 4 . The port 5 includes an input port and an output port, and the input port and the output port extend vertically to the metal cavity, and their width and depth are equal to the value ranges of the width and depth of the slot waveguide cross section.

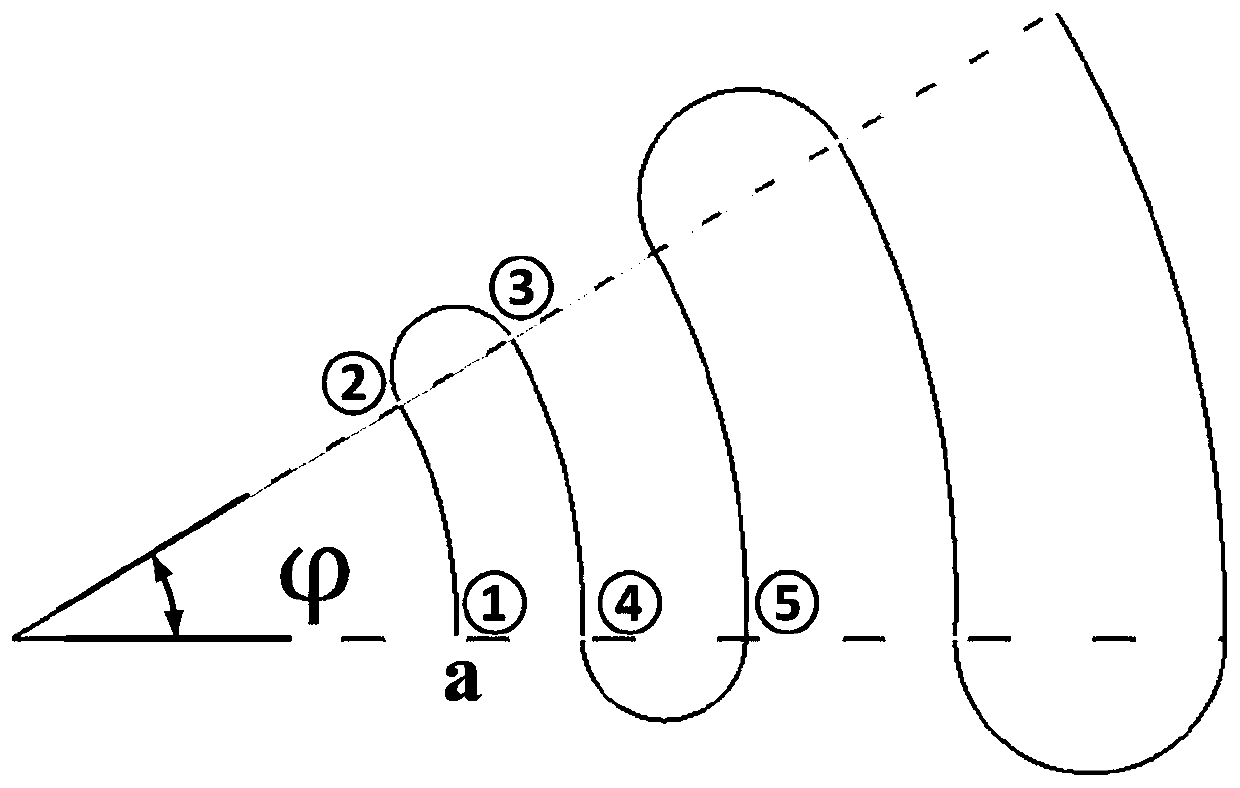

[0036] Working principle: In the angle logarithmic slot waveguide, when the electromagnetic wave propagates al...

Embodiment 2

[0039] The cross-section of the angle logarithmic slot waveguide is rectangular, the value of its width W can be 0.14 mm, the value of depth h can be 0.8 mm, and the value of thickness t of radial electron injection channel can be 0.12 mm; the present invention It solves the problem that the existing folded waveguide operates in the high-frequency band due to the high working voltage, which leads to internal failure and the problem that the device cannot be miniaturized, and achieves the generation of high-power electromagnetic waves in the terahertz band, effectively reducing the working voltage of the electric vacuum device, and correspondingly reducing the volume of the equipment. The miniaturization effect of the electric vacuum device is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com