Display module

A display module and display panel technology, applied in the directions of printed circuits, stacking and separating printed circuit boards, instruments, etc., can solve the problems of increasing the production cost of display devices, failing to meet miniaturization, and affecting the qualification rate of display device manufacturing processes, etc. The best reliability, lower production cost and smaller volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

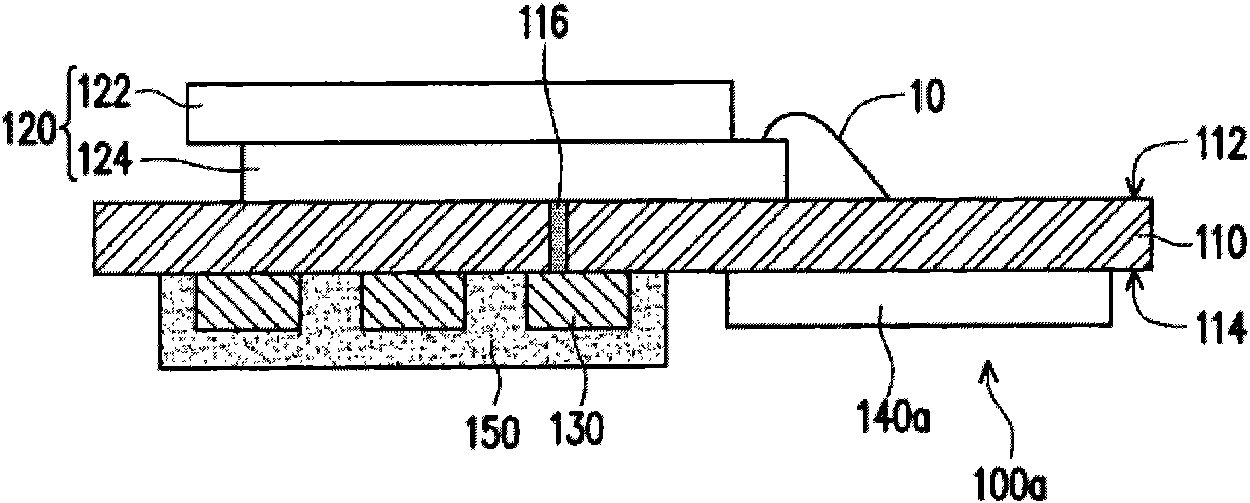

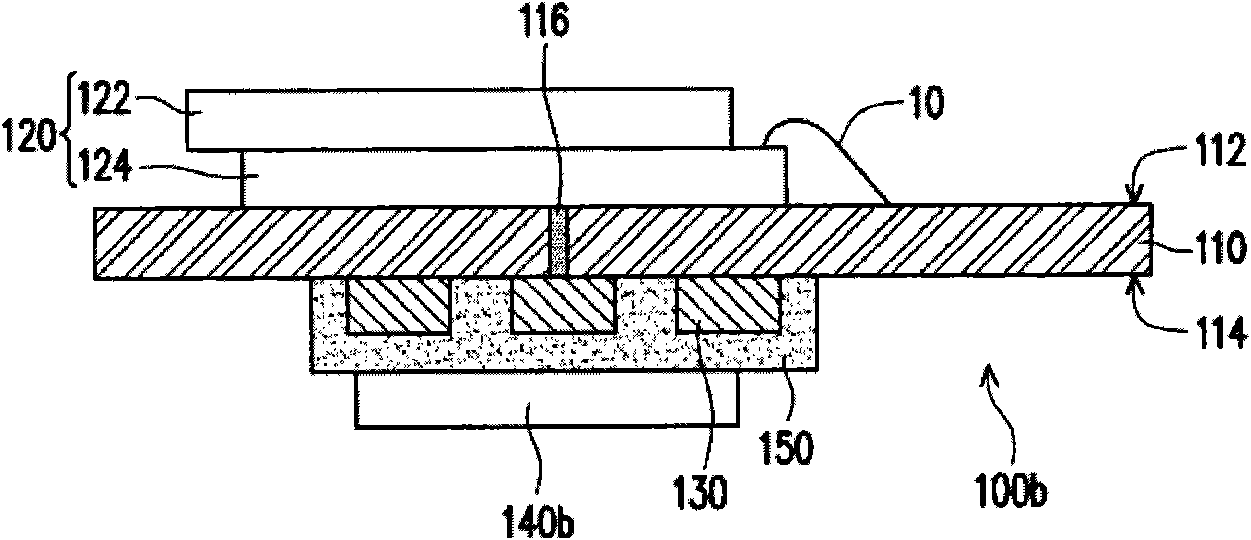

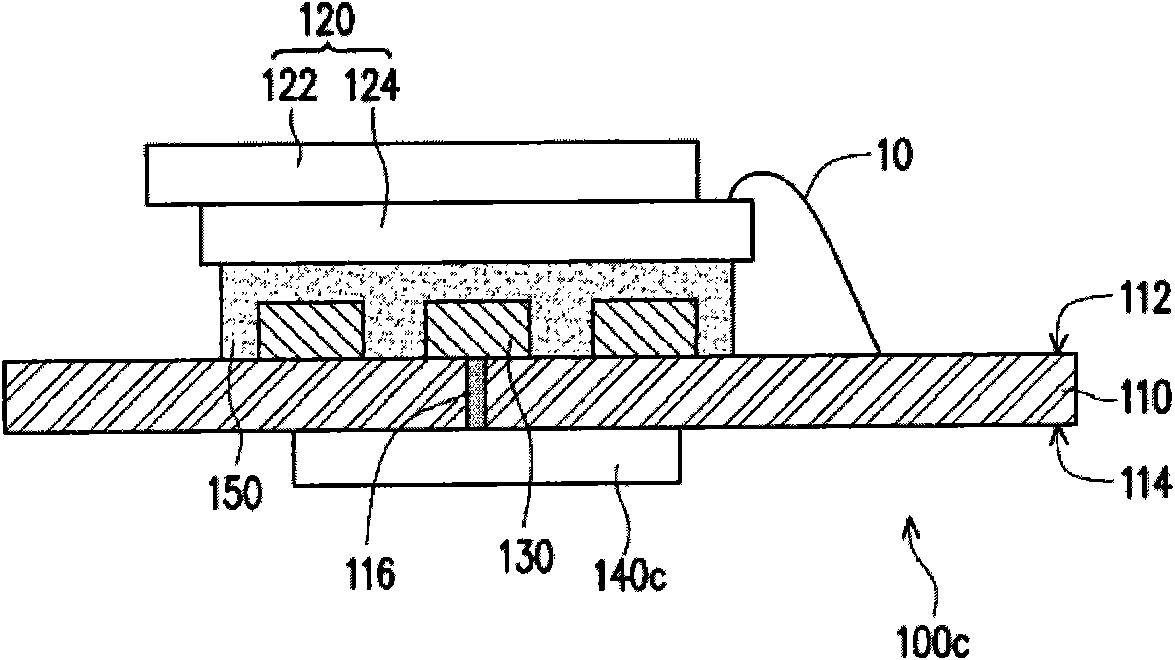

[0042] figure 1 It is a schematic cross-sectional view of a display module according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the display module 100a includes a first circuit board 110, a display panel 120 and at least one die 130 ( figure 1 Only three are shown schematically). Wherein, the first circuit board 110 is, for example, a flexible circuit board, a printed circuit board or a rigid-flex composite board, but it is not limited thereto.

[0043] In detail, the display panel 120 and the die 130 are respectively disposed on two opposite surfaces of the first circuit board 110, that is, the display panel 120 is located on a surface 112 of the first circuit board 110, and the die 130 is located on the first circuit board 110. on the other surface 114 of the circuit board 110 . The display panel 120 can be electrically connected to the first circuit board 110 through a bonding wire 10 , that is, the display panel 120 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com