Sliding plate driving assembly with mixed movement

A skateboard component and mixed motion technology, applied in the transmission device, wobble plate transmission device, inclined crank transmission device, etc., can solve the problems of bending moment rigidity, dynamic balance, complex structure, etc., to strengthen the overall structural rigidity and reduce surface rigidity Requirements, the effect of simple structure configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

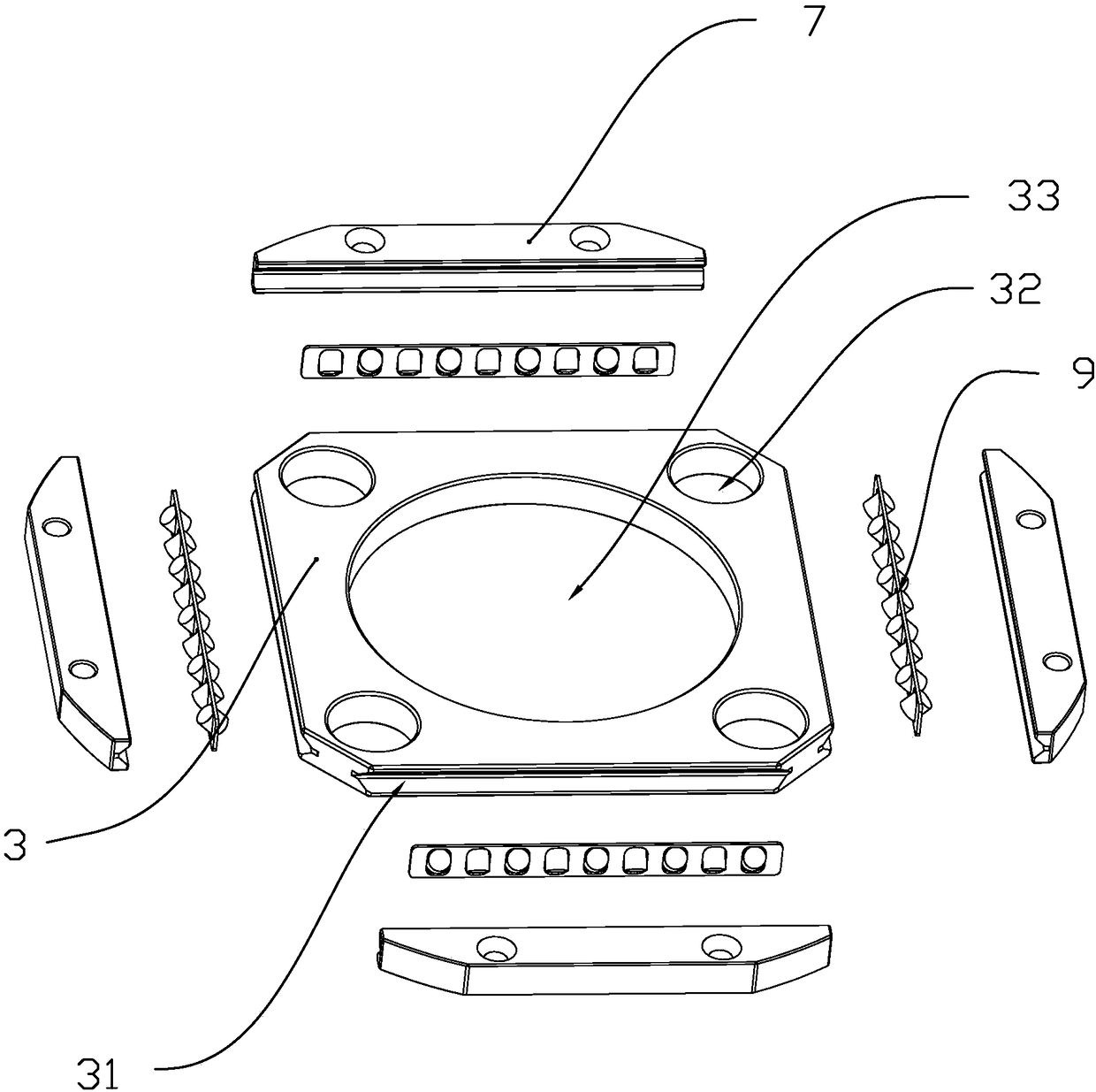

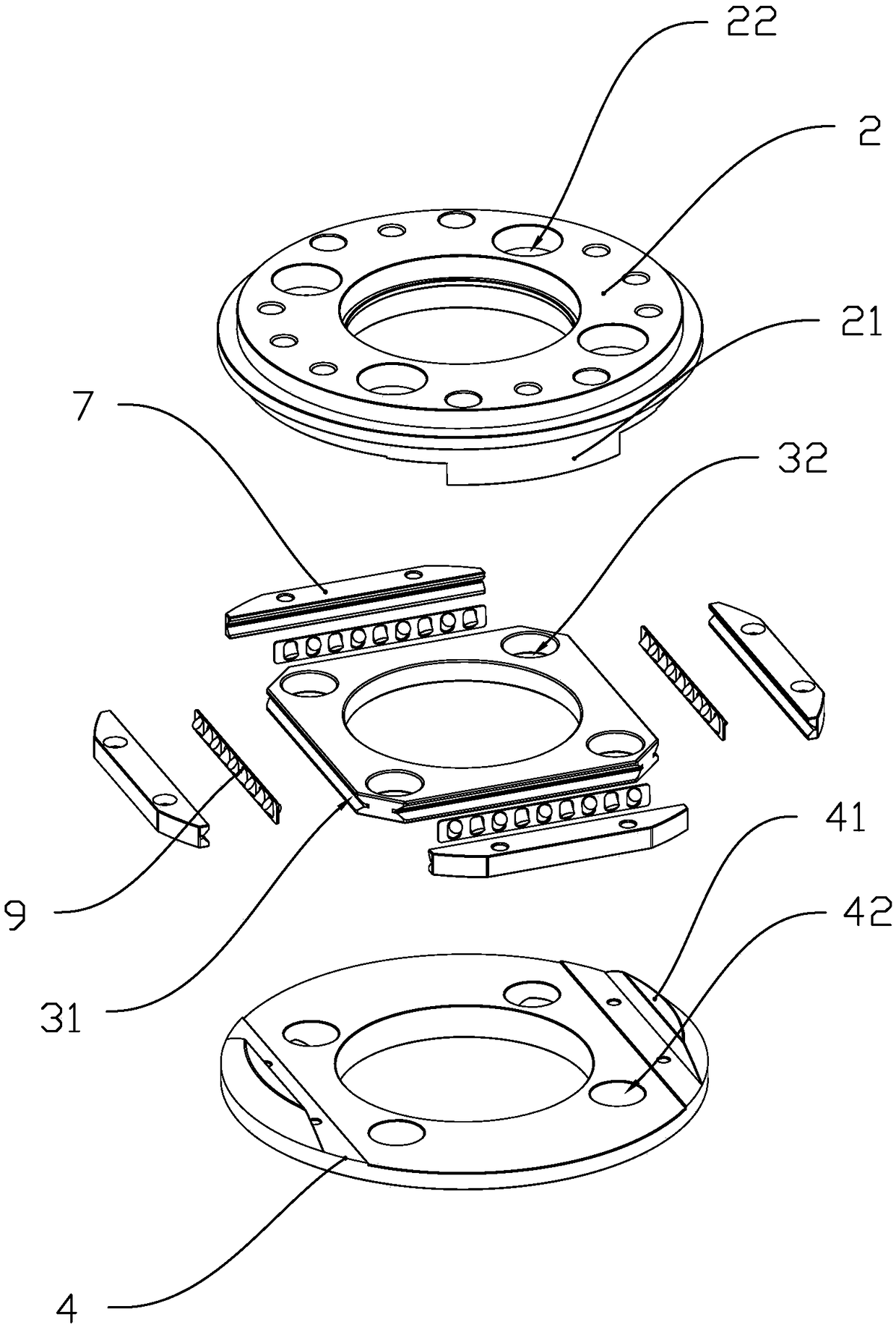

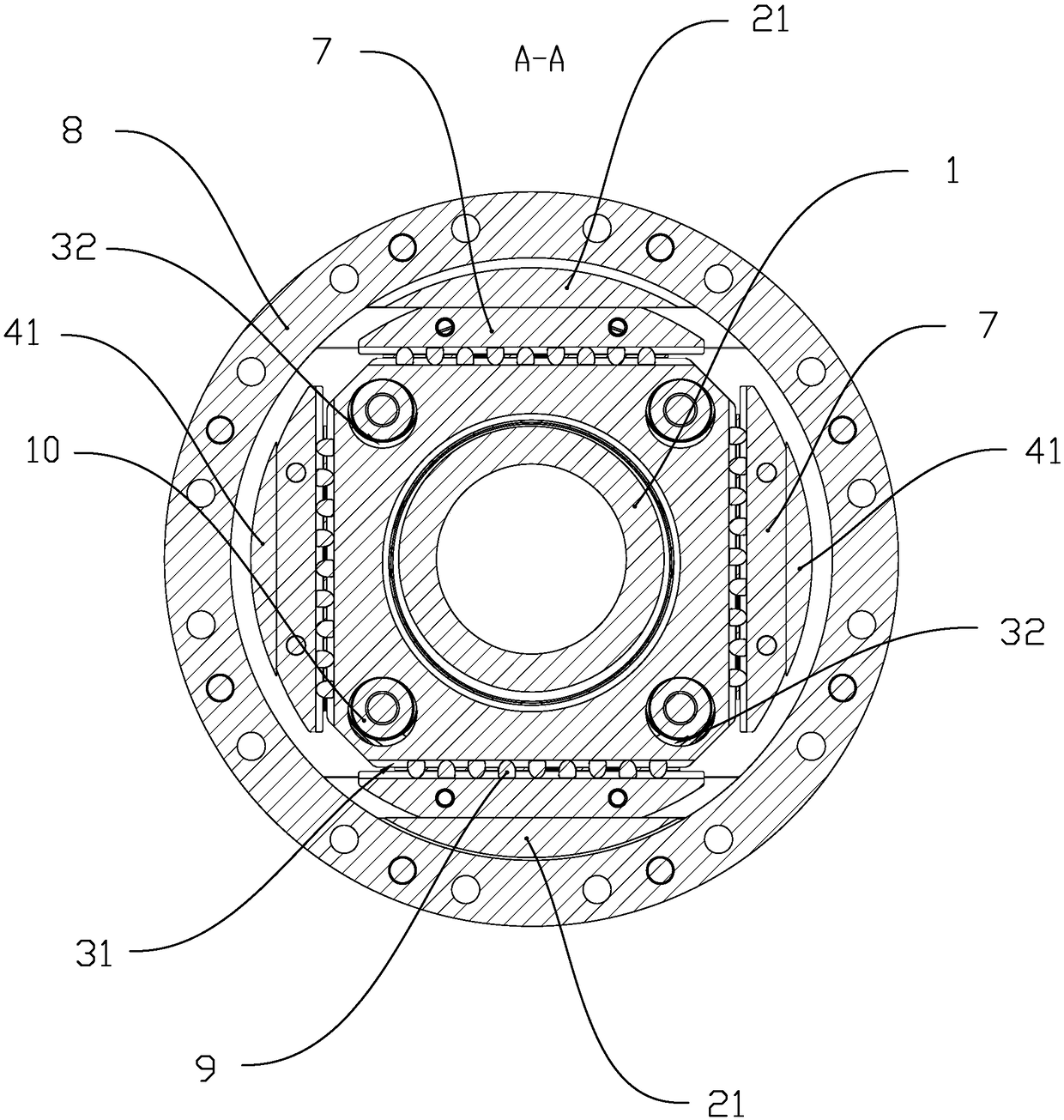

[0016] The parts in the accompanying drawings are marked as follows; 2. Output shaft, 3. Skateboard, 4. Drive plate, 7. Translating guide rail, 8. Body, 9. Cross roller, 10. Connecting pin, 21. Output shaft clamping block , 22, output shaft pin hole, 31, V-shaped groove, 32, slide plate pin hole, 41, drive disc clamping block, 42, drive disc pin hole.

[0017] The embodiment of the present invention is a technical solution applied to a cycloidal transmission (reducer), which includes a slide plate 3 body, which can be clamped by each driving member and driven member at the same time and form a radial sliding shaft with it. The clamping surface is clamped and matched with the rotation, and the clamping surface is provided with a mounting groove for accommodating the sliding part that cooperates with each driving part and driven part or its matching guide rail. The guide rail embodiment here is a translation guide rail 7, the driving part is the eccentrically driven driving disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com