Centrifugal pump enclosed impeller

A pump closed type, impeller technology, applied in the field of centrifugal pumps, can solve the problems of difficult processing, leakage of the sealing ring in front of the impeller, high matching accuracy and clearance requirements, and achieves convenient installation, reduces processing accuracy requirements and assembly accuracy requirements, Simple and efficient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

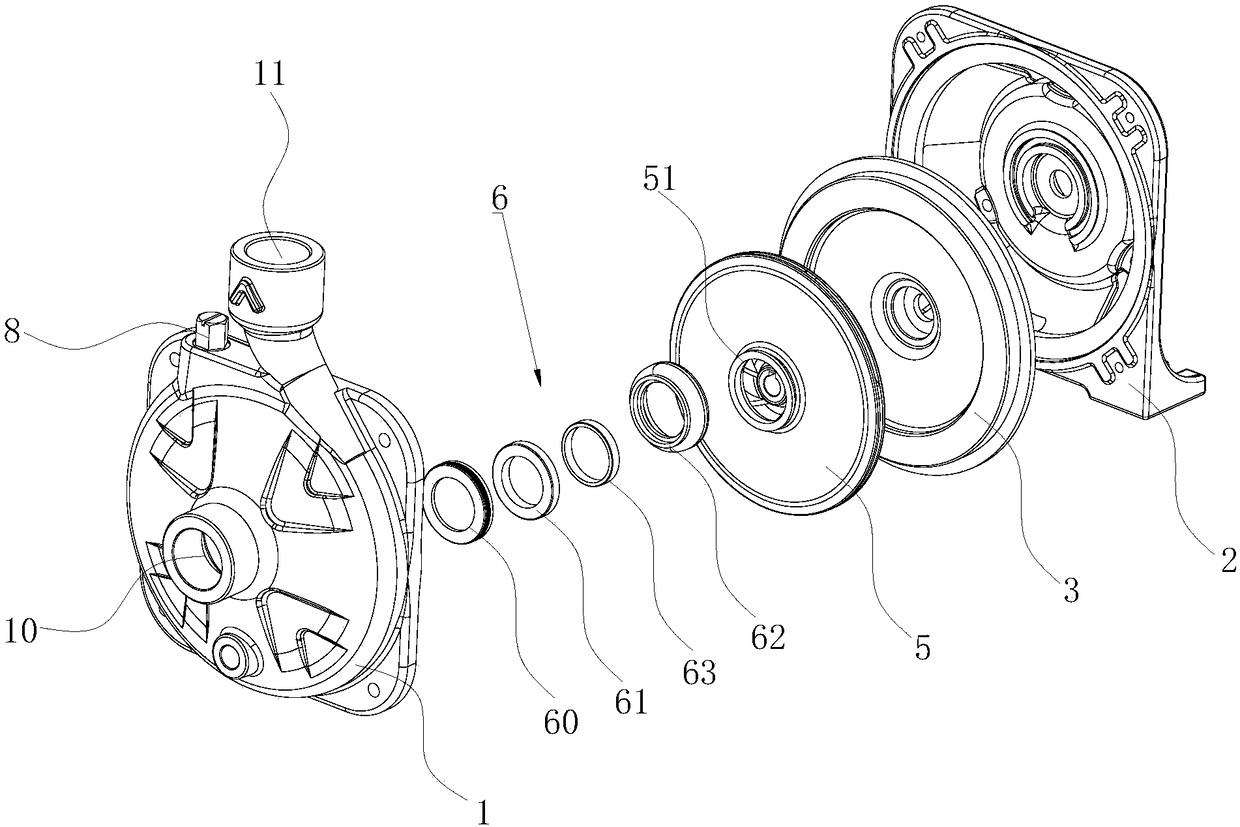

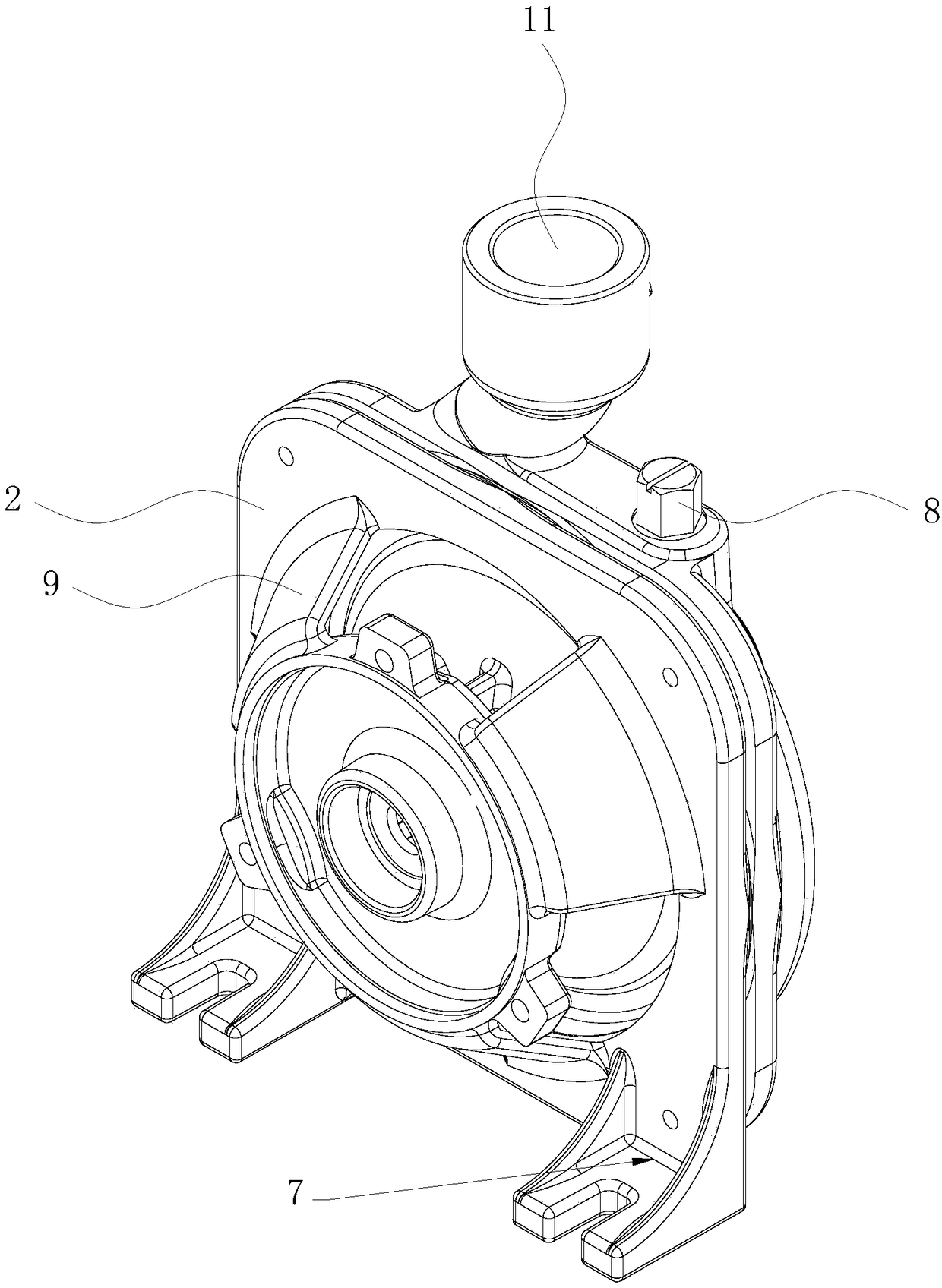

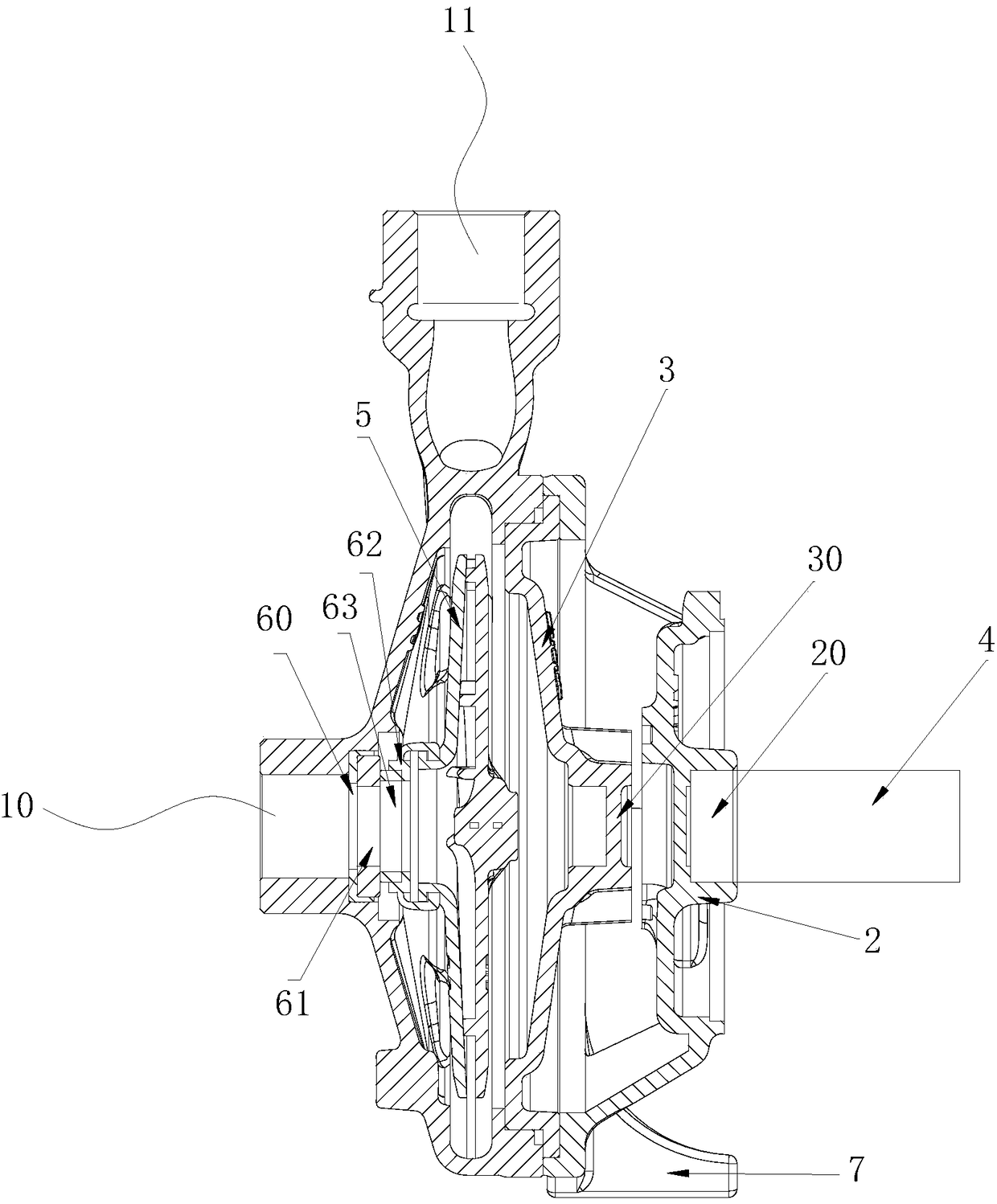

[0044] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0045] see figure 1 , figure 2 and image 3 , The invention provides a closed impeller of a centrifugal pump, which is used to provide rotational force for the pump body. The centrifugal pump works by using the impeller to rotate to cause the water to undergo centrifugal motion. Before starting the pump, the pump casing and the suction pipe must be filled with water, and then the motor is started, so that the pump shaft connected to the drive shaft drives the impeller and the water to rotate at a high speed, and the water undergoes centrifugal motion and is thrown to the outer edge of the impeller. The flow channel of the volute pump casing flows into the pressure water pipeline of the water pump.

[0046] In a specific embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com