Bed-parallel drilling slot pressure relief permeability increase method

A technology of bedding drilling and slotting, which is applied in the field of bedding drilling and slotting for pressure relief and antireflection, and can solve problems such as the inability to fundamentally ensure safe and efficient production of the mining face, inability to relieve pressure and increase the permeability of coal seams, and induce outbursts, etc. problems, to achieve the effect of widely popularizing the application value, good drainage effect, and reducing the stress level of coal mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

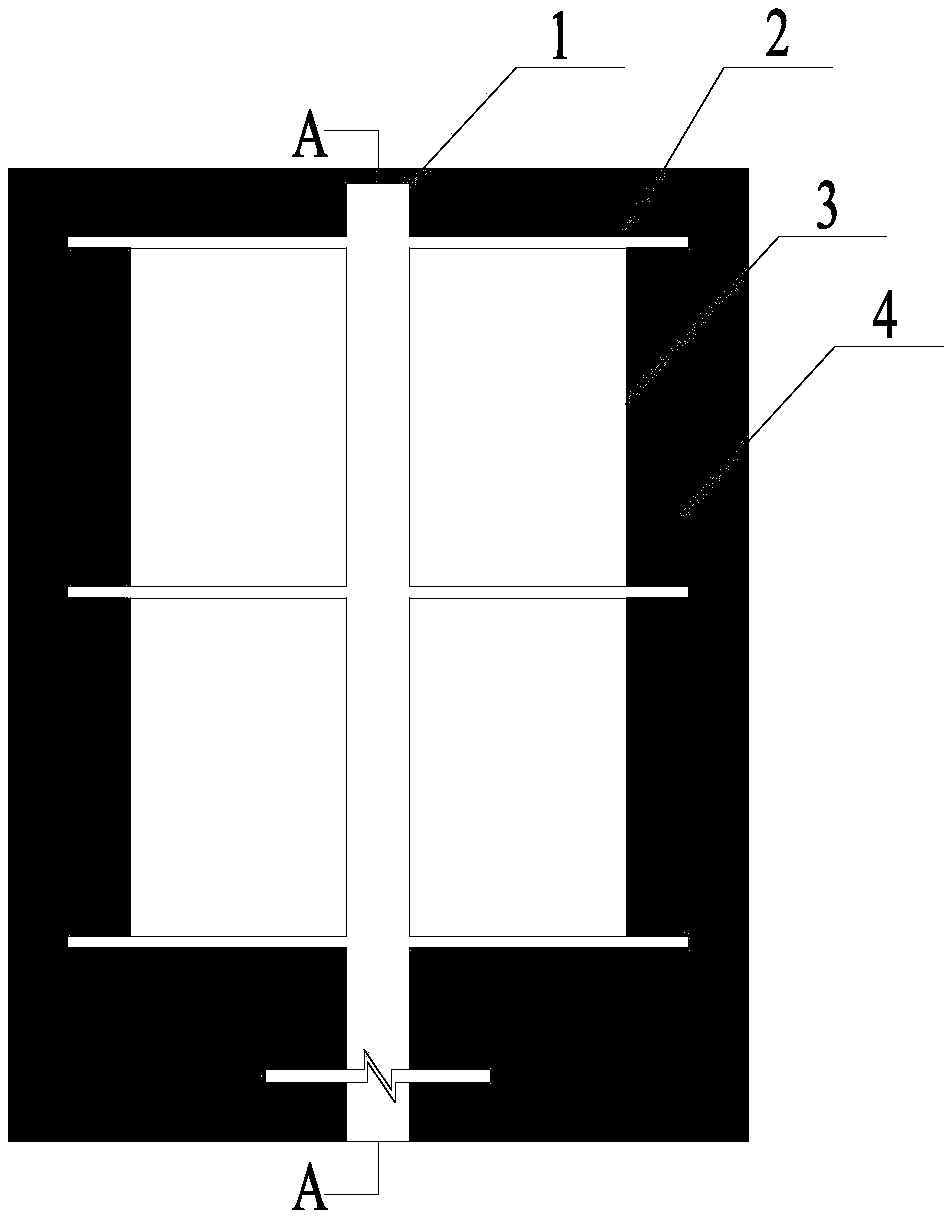

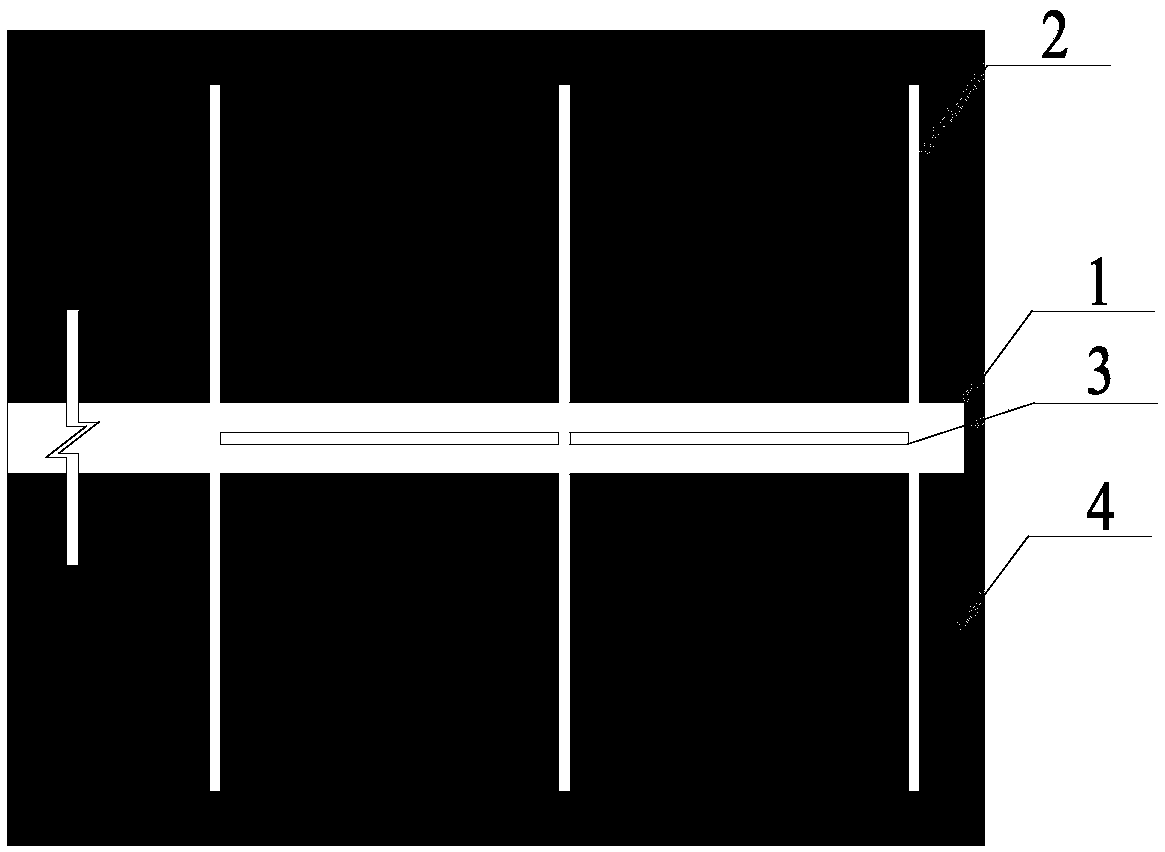

[0030] As shown in the figure, the method for pressure relief and antireflection of layer-by-layer drilling and slotting in this embodiment includes the following steps:

[0031] (1) According to the design requirements of bedding gas drainage drilling, the bedding gas drainage drilling 1 is respectively constructed in the coal body 4 of the transportation trough 5 and the track trough 6 on the mining face, that is, the high-pressure hydraulic slotting device is used Construction bedding gas drainage borehole 1 is formed to form borehole 1; the length of the borehole is 80-180m; the high-pressure hydraulic slotting device can be the structure disclosed in CN 106150500 A, which will not be repeated here, and its rated pressure is 100- 150MPa, the rated flow rate is 80-125L / min.

[0032] (2) Without retreating the drill, feed high-pressure water into the high-pressure hydraulic cutting device to cut the coal body in a circular and circular direction to form a disc-shaped slot; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com