Bridge vertical column construction operation platform

An operating platform and workbench technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient safety guarantee and single structure, and achieve the effects of enhanced safety guarantee, convenient use and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

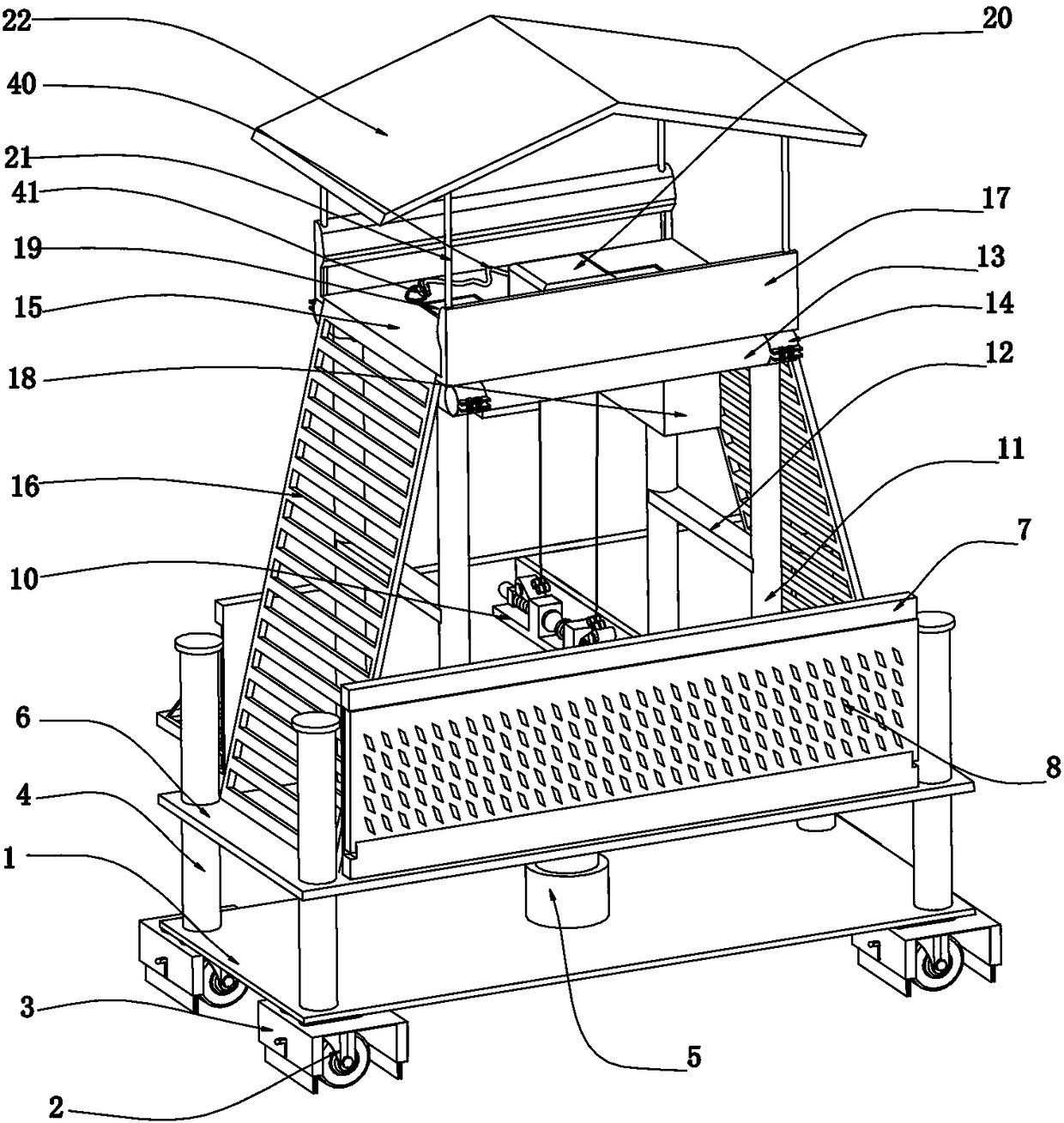

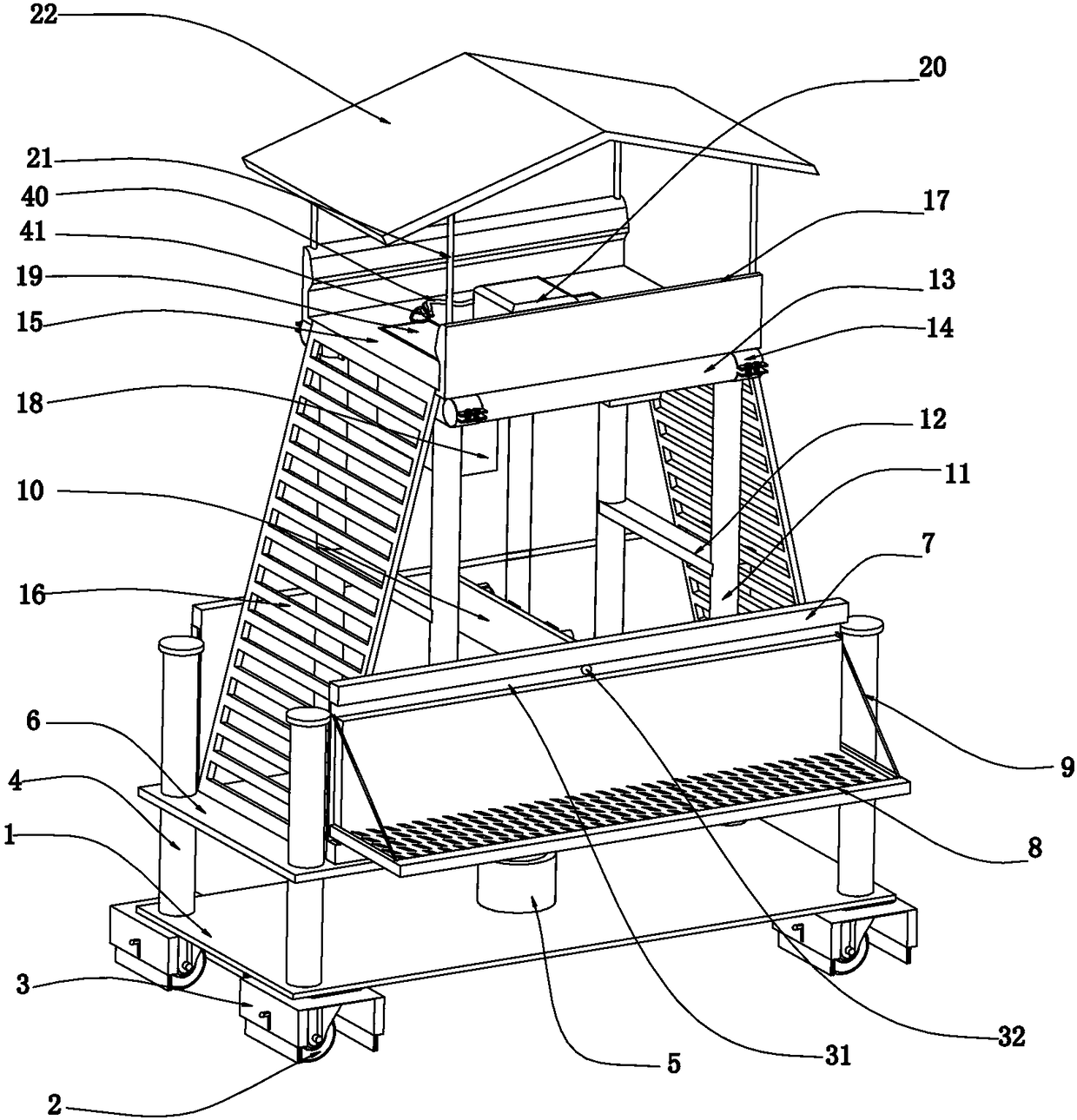

[0034] Embodiment 1. The present invention is a bridge column construction operation platform, which includes a rectangular bottom plate 1. In order to make the construction operation platform move more conveniently, the lower end of the bottom plate 1 is fixedly connected with four universal wheels 2 by bolts. In order to make the construction operation platform The device is more stable when working. The four universal wheels 2 are all equipped with a brake system 3. When the sliding plate 3-2 of the brake system 3 is put down, it can touch the ground to complete the fixation. The friction pad or pointed cone installed at the lower end of the sliding plate 3-2 The block will strengthen the braking strength, keep the stability of the device, make the universal wheel 2 stop displacement, and the construction operation platform is fixed; the upper edge of the bottom plate 1 is integrally connected or welded with four vertically arranged guide columns 4, and the guide columns 4 pl...

Embodiment 2

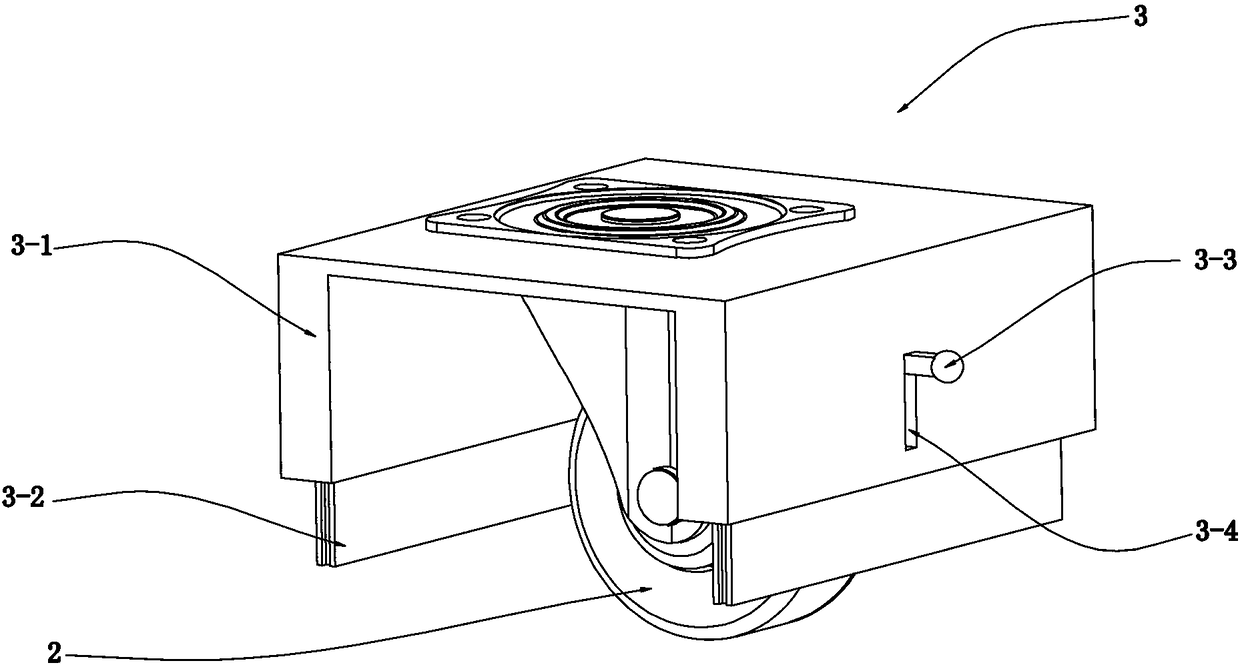

[0042] Embodiment 2. On the basis of Embodiment 1, the brake system 3 includes a U-shaped guide rail 3-1 installed around the universal wheel 2, and two sliding plates 3-1 that are slidably connected to the U-shaped guide rail 3-1. 2, see image 3 , the two sliding plates 3-2 slide inside the U-shaped guide rail 3-1, the two sliding plates 3-2 are equipped with handles 3-3, the U-shaped guide rail has a rectangular chute 3-4, and the handle 3-4 is pulled 3. The lower ends of the two sliding plates 3-2 can touch the ground; when the construction operation platform needs to be moved, the handle 3-3 is lifted up, and the sliding plate 3-2 slides upwards to push the construction operation platform. When fixing, the handle 3-3 is pulled down, and the sliding plate 3-2 slides downward, and the lower end of the sliding plate 3-2 touches the ground, and the lower end of the sliding plate 3-2 is equipped with a friction pad or a sharp cone block, which can effectively strengthen the br...

Embodiment 3

[0043] Embodiment 3, on the basis of Embodiment 1, four guide columns 4 run through the middle plate 6, and the height of the guide columns 4 is equal to the maximum height of the lifting rod 5. The existence of the guide columns 4 plays a guiding role, and for The construction operation platform plays a supporting role, and the top of the guide column 4 is set in a boss shape, which limits the position of the middle plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com