Construction method for straddle type monorail prefabricated steel-HPC (High Performance Concrete) combined track beam

A straddle-type monorail and construction method technology, applied in the field of rail transit, can solve the problems of affecting the durability and integrity of the structure, easy cracking of concrete, complicated stress on the connecting surface, etc., to achieve convenient operation and reduce shrinkage cracks. Risks and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

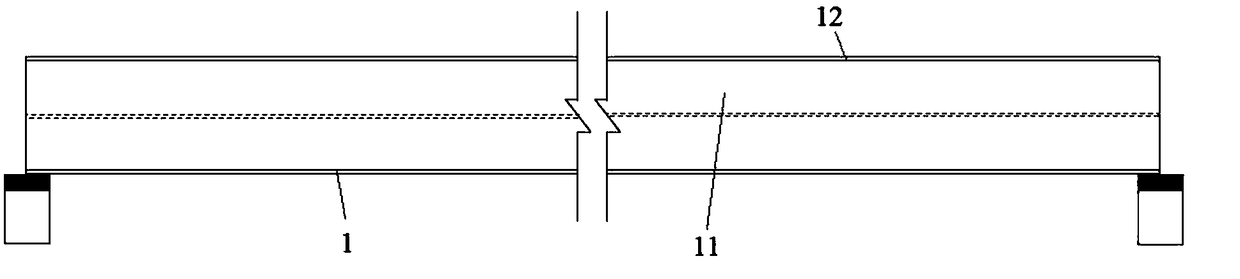

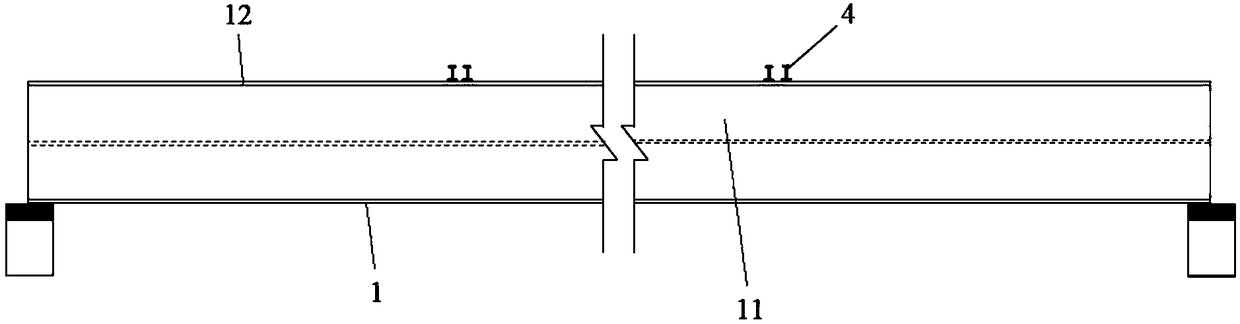

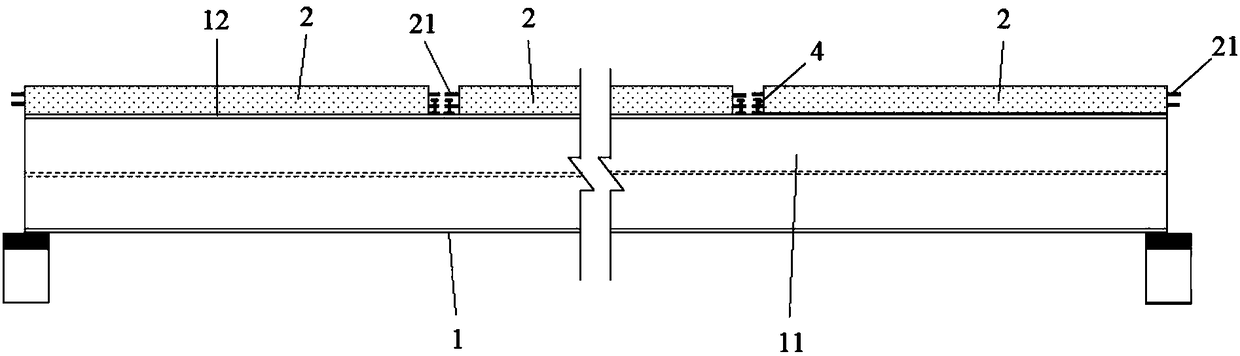

[0061] Such as Figure 1-8 , Shown in 11 and 12, the construction method of a kind of straddle type monorail prefabricated assembly type steel-HPC composite track girder of the present invention, comprises the following steps:

[0062] A. If figure 1 As shown, the steel box 1 and the prefabricated HPC board 2 are manufactured at the beam manufacturing site;

[0063] B. If figure 2 As shown, each wet joint 3 section on the top of the steel box 1 is provided with a connecting part 4;

[0064] C. If image 3 As shown, the prefabricated HPC panels 2 are hoisted and positioned on the steel box 1, and between two adjacent prefabricated HPC panels 2 is the corresponding section of the wet joint 3, wherein each of the prefabricated HPC panels 2. There are several extended longitudinal main ribs 21 at the end face;

[0065] D. Correspondingly setting the extended longitudinal main ribs 21 between two adjacent prefabricated HPC panels 2;

[0066] E. If Figure 4 As shown, all th...

Embodiment 2

[0078] Such as Figure 9-12 As shown, the construction method of a straddle-type monorail prefabricated steel-HPC composite track beam of the present invention comprises the following steps:

[0079] a. Make steel box 1 and prefabricated HPC board 2 at the beam making place, and several vertical through holes 22 are set on the prefabricated HPC board 2;

[0080] b. The top of the steel box 1 corresponding to each of the through holes 22 is provided with a connecting part 4;

[0081]c. Lift the prefabricated HPC board 2 and position it on the steel box 1, so that each connecting part 4 fits the corresponding through hole 22, and the corresponding said through hole 22 is between two adjacent prefabricated HPC boards 2. Wet joint 3 sections, wherein each of the prefabricated HPC panels 2 end faces is provided with several extended longitudinal main ribs 21;

[0082] d. The extended longitudinal main ribs 21 on the end faces of two adjacent prefabricated HPC panels 2 are arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com