Straddle type single-track prefabricated assembling steel-HPC (High Performance Concrete) combined track beam

A straddle-type monorail and prefabricated assembly technology, which is applied in the field of rail transit, can solve the problems affecting the durability and integrity of the structure, the concrete is prone to cracks, and the stress on the connecting surface is complicated, so as to achieve good durability and integrity of the structure , reduce the risk of shrinkage cracks, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

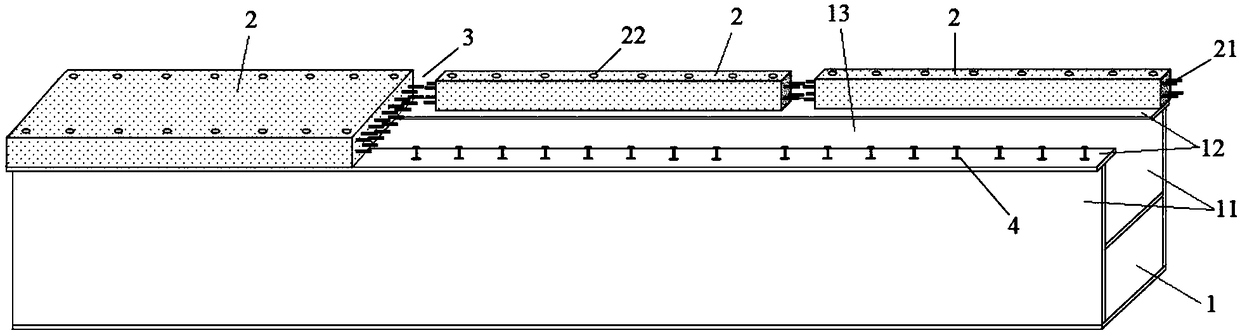

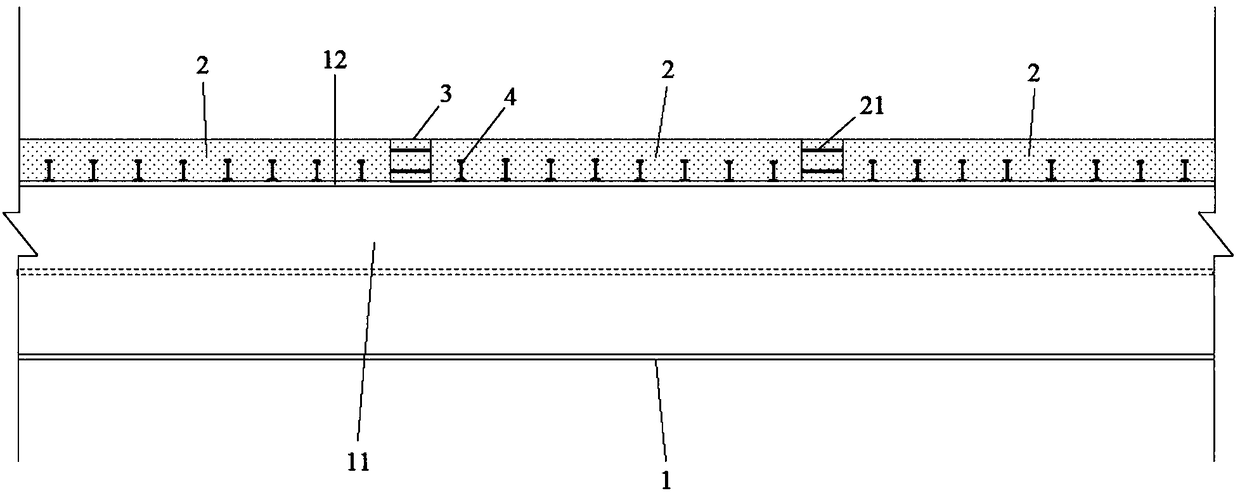

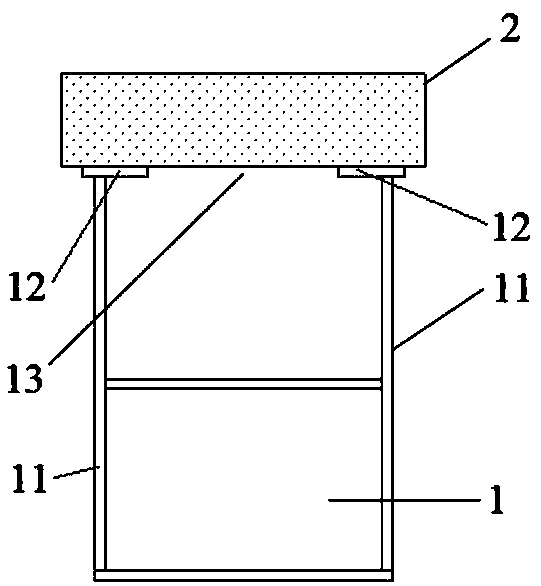

[0038] Such as Figure 1-4 As shown, a straddle type monorail prefabricated steel-HPC composite track beam according to the present invention includes a steel box 1 .

[0039] The steel box 1 includes a web 11 and a top plate 12, and several prefabricated HPC panels 2 are arranged on the top panel 12, and several vertical through holes 22 are arranged on each of the prefabricated HPC panels 2, and each of the through holes 22 corresponding to the top plate 12 is provided with a connecting part 4, the steel box 1 and all the prefabricated HPC panels 2 are connected by pouring all the through holes 22, and the length of each prefabricated HPC panel 2 is greater than 8 meters.

[0040] As a preferred solution of this embodiment, the port on one side of each through-hole 22 close to the top plate 12 is smaller than the port on the other side. With this structure, the through-hole 22 has an up and down effect on the prefabricated HPC board 2 after pouring. Limiting effect. Sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com