Preparation method of hydrophilic chitosan modified basalt fiber support

A basalt fiber, chitosan modification technology, applied in fiber treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of poor surface hydrophilicity and few surface active groups, and achieve low cost, Improves hydrophilicity and accelerates growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

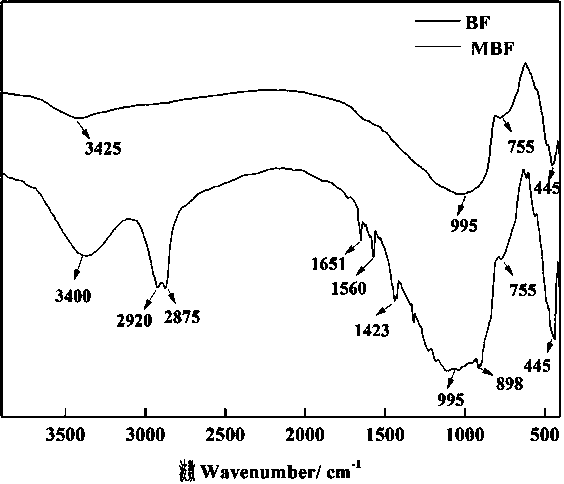

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of hydrophilic chitosan modified basalt fiber carrier, comprises the steps:

[0029] (1) Prepare a 0.5mol / L KOH solution, soak the basalt fiber (BF) in the KOH solution, take it out after 1 hour, rinse it with deionized water until neutral, and dry it for later use;

[0030] (2) preparation concentration is 0.2wt.% CH 3 COOH solution, weigh a certain amount of chitosan and dissolve it in CH 3 In the COOH solution, stir for 3h to obtain a chitosan solution with a concentration of 0.5wt.%.

[0031] (3) Soak the dried basalt fiber in step (1) in the chitosan solution in step (2), take it out after soaking at room temperature for 2h, and move it to a vacuum oven for drying to obtain modified basalt fiber Vector (MBF-1);

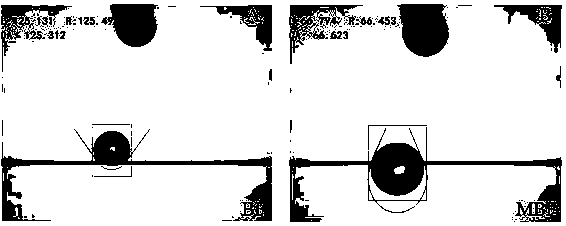

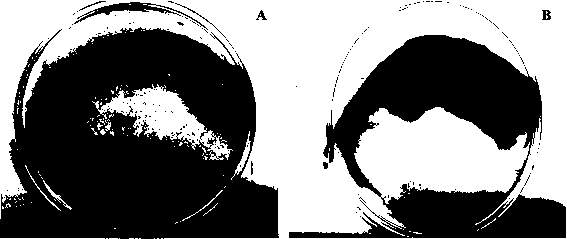

[0032] The basalt fibers (BF and MBF-1) before and after modification were made into umbrella-shaped carriers, and the film-hanging experiments were carried out on the two carriers. The amount of microbial attachment is rep...

Embodiment 2

[0034] A kind of preparation method of hydrophilic chitosan modified basalt fiber carrier, comprises the steps:

[0035] (1) Prepare a 1mol / L NaOH solution, soak the basalt fiber (BF) in the NaOH solution, take it out after 0.5h, rinse it with deionized water until neutral, and dry it for later use;

[0036] (2) preparation concentration is 0.2wt.% CH 3 COOH solution, weigh a certain amount of chitosan and dissolve it in CH 3 In the COOH solution, stir for 5h to obtain a chitosan solution with a concentration of 1.5wt.%.

[0037] (3) Soak the dried basalt fiber in step (1) in the chitosan solution in step (2), take it out after soaking at room temperature for 4h, and move it to dry in a vacuum oven to obtain modified basalt fiber Vector (MBF-2).

[0038] The basalt fibers (BF and MBF-2) before and after modification were made into umbrella-shaped carriers, and the film-hanging experiments were carried out on the two carriers. The amount of microbial attachment is represent...

Embodiment 3

[0040] A kind of preparation method of hydrophilic chitosan modified basalt fiber carrier, comprises the steps:

[0041] (1) Prepare a 1mol / L NaOH solution, soak the basalt fiber in the NaOH solution, take it out after 1h, rinse it with deionized water until neutral, and dry it for later use;

[0042] (2) preparation concentration is 0.2wt.% CH 3 COOH solution, weigh a certain amount of chitosan and dissolve it in CH3 In the COOH solution, stir for 4h to obtain a chitosan solution with a concentration of 1.5wt.%.

[0043] (3) Soak the dried basalt fiber in step (1) in the chitosan solution in step (2), take it out after soaking at room temperature for 2h, and move it to a vacuum oven for drying to obtain modified basalt fiber Vector (MBF-3).

[0044] The basalt fibers (BF and MBF-3) before and after modification were made into umbrella-shaped carriers, and the film-hanging experiments were carried out on the two carriers. The amount of microbial attachment is represented by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com